A kind of manufacturing method of capacitive touch screen

A technology of capacitive touch screen and manufacturing method, which is applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of increasing the production cost of touch screen, and achieve saving of magnetron sputtering equipment and spin coating equipment , reduce material costs, improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention aims to provide a capacitive touch screen solution which simplifies the process and reduces the product price. Its core is to realize the production of capacitive touch screen through the following technical measures:

[0038] 1. Patterning of the conductive film on both sides of the substrate;

[0039] 2. Use silk screen metal paste as the wire.

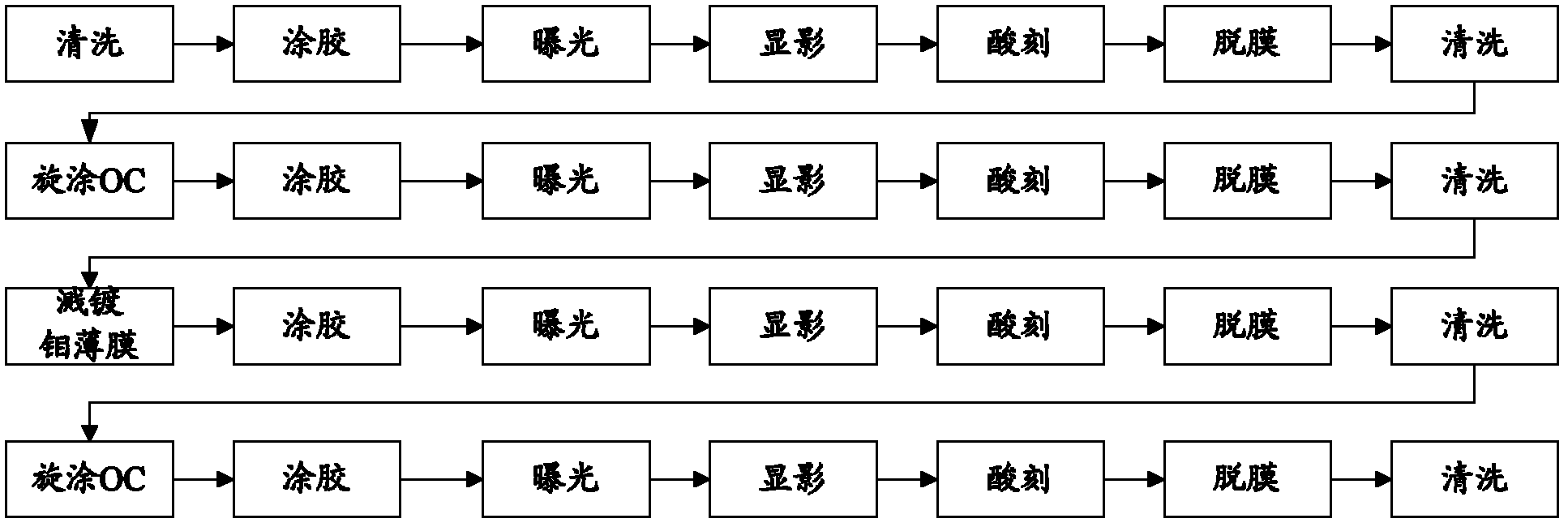

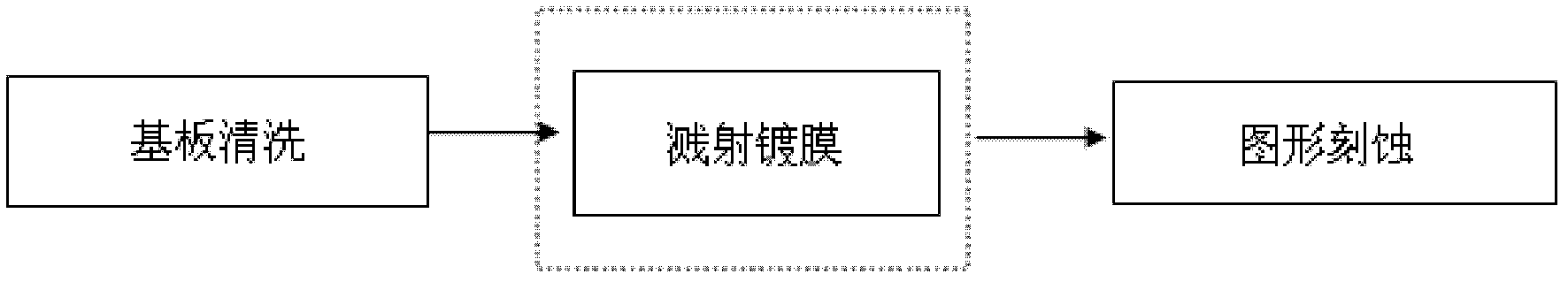

[0040] Specifically, the manufacturing process of the touch screen electrode of the capacitive touch screen of the present invention includes the following steps:

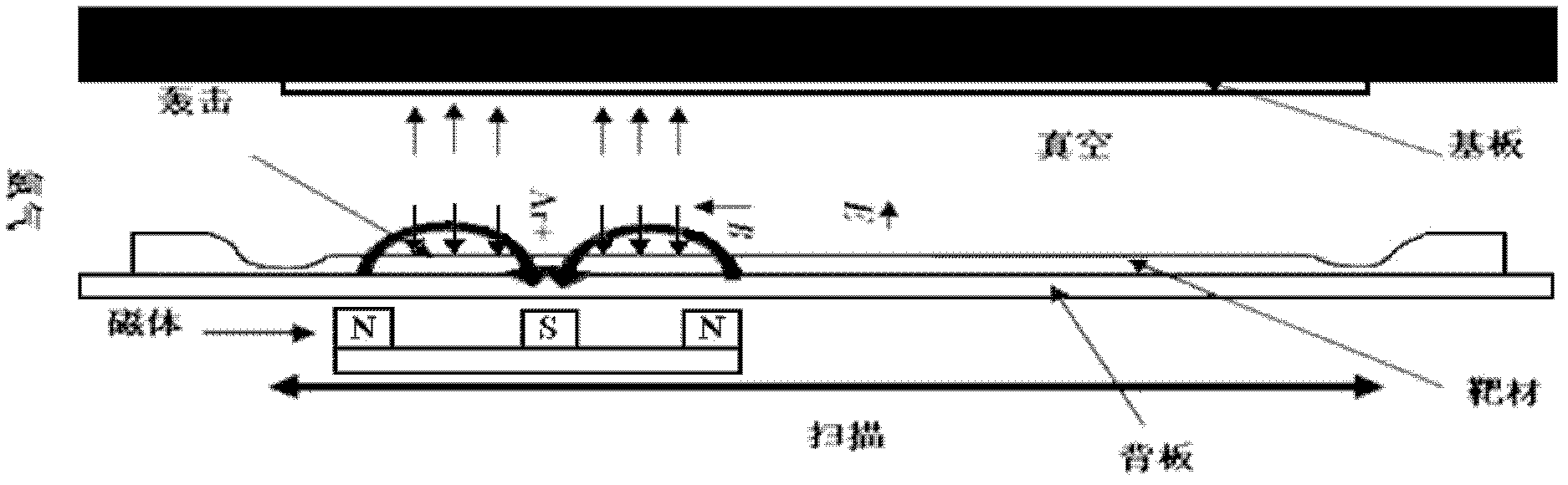

[0041] Pattern the conductive film on the first surface (made of materials such as indium tin oxide, aluminum zinc oxide, etc.) and the conductive film on the second surface of the substrate (made of transparent materials such as glass and plexiglass) to form the first set of sensing electrodes and a second set of sensing electrodes;

[0042] Conductor production process, screen printing metal paste (such as silver paste, silver-aluminum paste, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com