A suspension string of composite insulators for overhead transmission lines

A technology for overhead transmission lines and composite insulators, which is applied in the direction of circuits, insulators, suspension/strain insulators, etc., which can solve the problems of mechanical performance degradation, weakening the connection strength of mandrel and end fittings, etc., and achieve the effect of ensuring mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

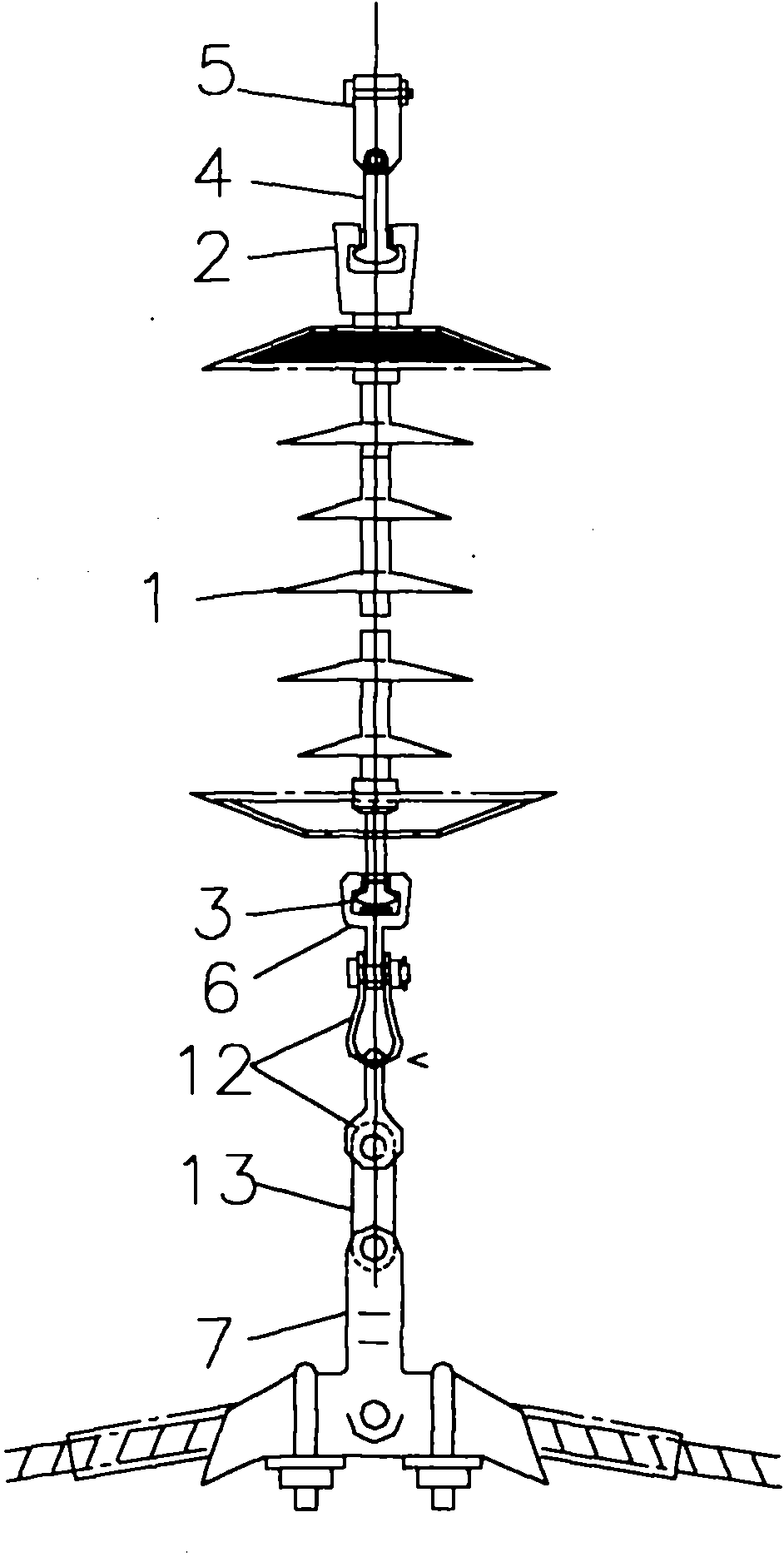

[0022] Embodiment 1, a kind of overhead transmission line composite insulator single wire suspension string (see figure 1 ), which includes a composite insulator 1. The upper end of the composite insulator 1 is provided with a ball socket structure 2, and the lower end is provided with a ball joint structure 3. The ball socket structure 2 is connected to the grounding terminal fittings string, and the grounding terminal fittings string is connected by a QP type ball joint hanging ring 4 and the UB hanging plate 5 are connected to form, and the QP type ball joint hanging ring 4 is connected with the ball-and-socket structure 2. The ball head structure 3 connects the high-voltage end fittings string, and the high-voltage end fittings string consists of a bowl head hanging plate 6, an inner arc U-shaped ring 12 connected by two rings, a PD hanging plate 13, and a suspension clamp 7 (holding the wire) The structure is connected in turn, and the bowl head hanging plate 6 is connect...

Embodiment 2

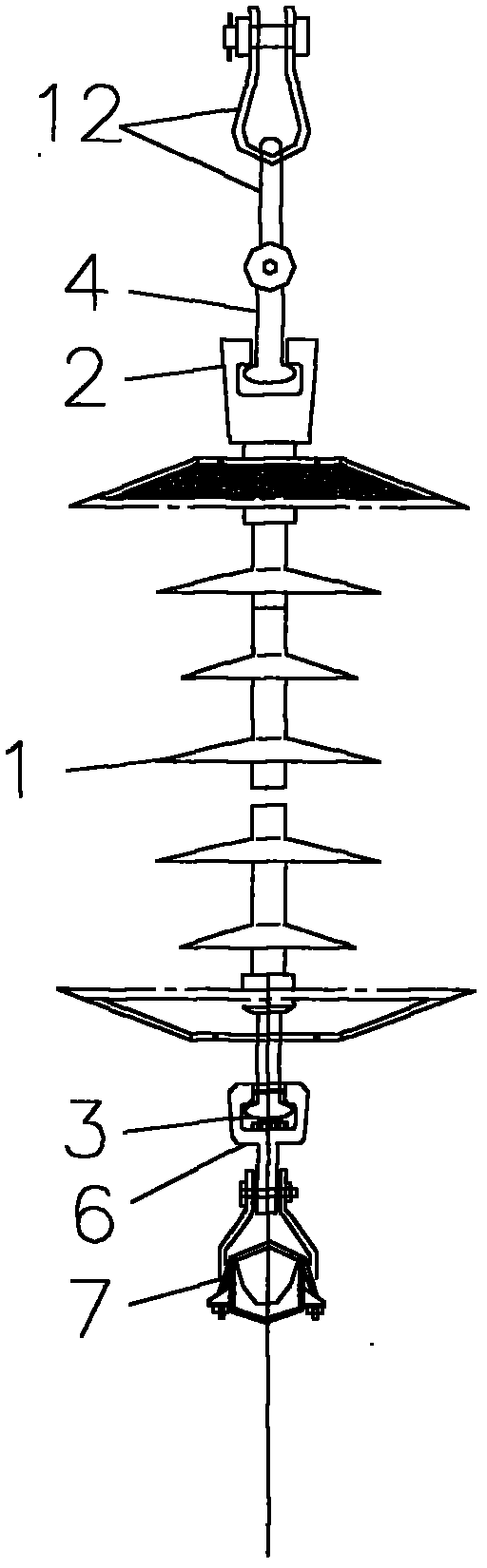

[0023] Embodiment 2, a kind of overhead transmission line composite insulator single wire suspension string (see figure 2 ), which includes a composite insulator 1. The upper end of the composite insulator 1 is provided with a ball socket structure 2, and the lower end is provided with a ball joint structure 3. The ball socket structure 2 is connected to the grounding terminal fittings string, and the grounding terminal fittings string is connected by a QP type ball joint hanging ring 4 is connected with two inner arc U-shaped rings 12 connected by ring-ring, and the QP type ball joint hanging ring 4 is connected with the ball-and-socket structure 2. The ball head structure 3 is connected to the high-voltage end fittings string, and the high-voltage end fittings string is formed by sequentially connecting the bowl head hanging plate 6 and the suspension wire clamp 7 , and the bowl head hanging plate 6 is connected to the ball head structure 3 .

Embodiment 3

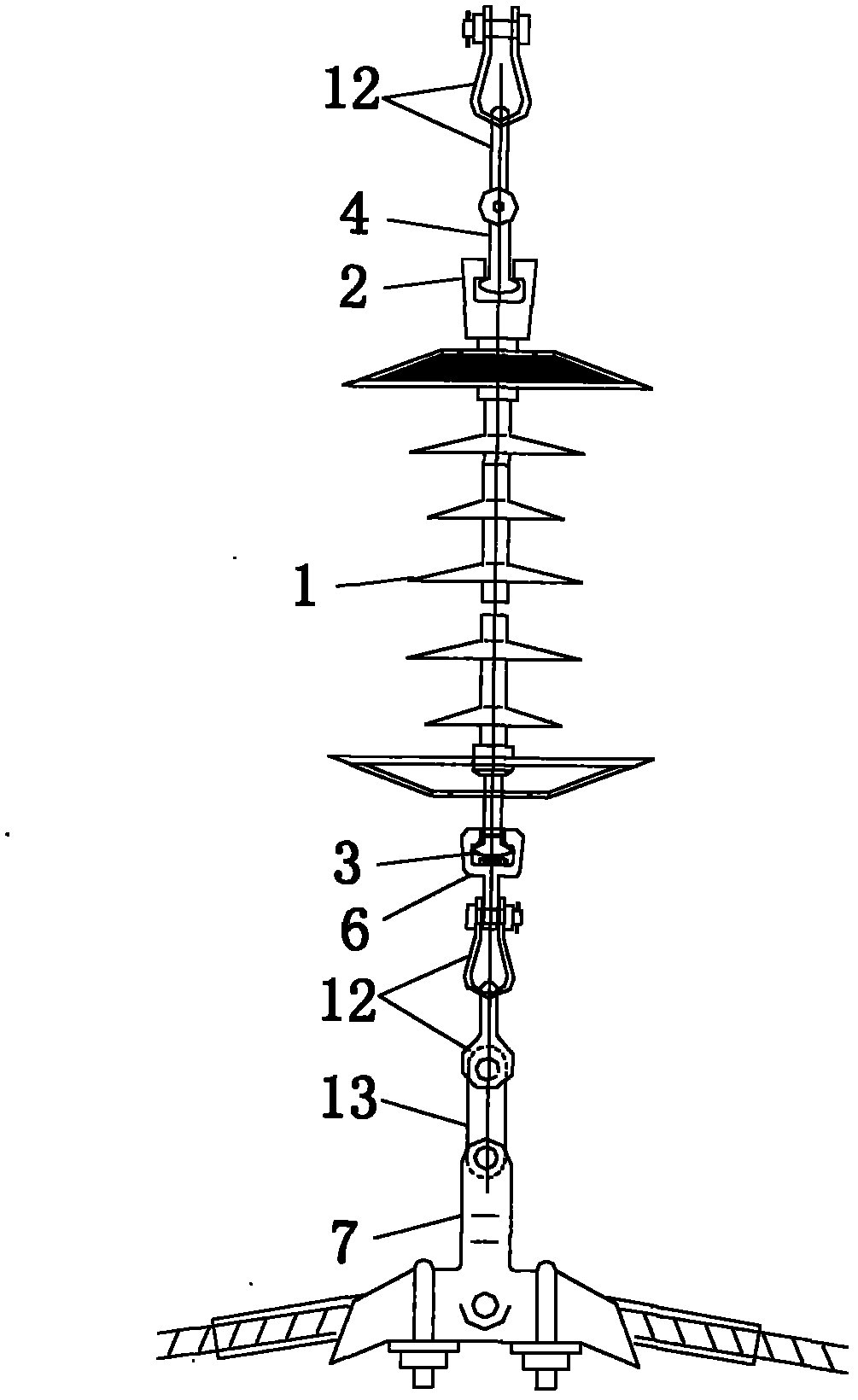

[0024] Embodiment 3, a kind of overhead transmission line composite insulator single wire suspension string (see image 3 ), which includes a composite insulator 1. The upper end of the composite insulator 1 is provided with a ball socket structure 2, and the lower end is provided with a ball joint structure 3. The ball socket structure 2 is connected to the grounding terminal fittings string, and the grounding terminal fittings string is connected by a QP type ball joint hanging ring 4 is connected with two inner arc U-shaped rings 12 connected by ring-ring, and the QP type ball joint hanging ring 4 is connected with the ball-and-socket structure 2. The ball head structure 3 connects the high-voltage end fittings string, and the high-voltage end fittings string consists of a bowl head hanging plate 6, an inner arc U-shaped ring 12 connected by two rings, a PD hanging plate 13, and a suspension clamp 7 (holding the wire) The structure is connected in turn, and the bowl head ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com