Non-metallic box-type substation shell, its manufacturing process, and exterior wall mold

A box-type substation, non-metallic technology, applied in the substation/distribution device shell, substation/switch layout details, electrical components, etc., can solve the problems of increased transportation costs, increased procedures, complex processing, etc., to achieve simple manufacturing process, The effect of simplifying the manufacturing process and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (Embodiment 1, non-metallic box-type substation housing)

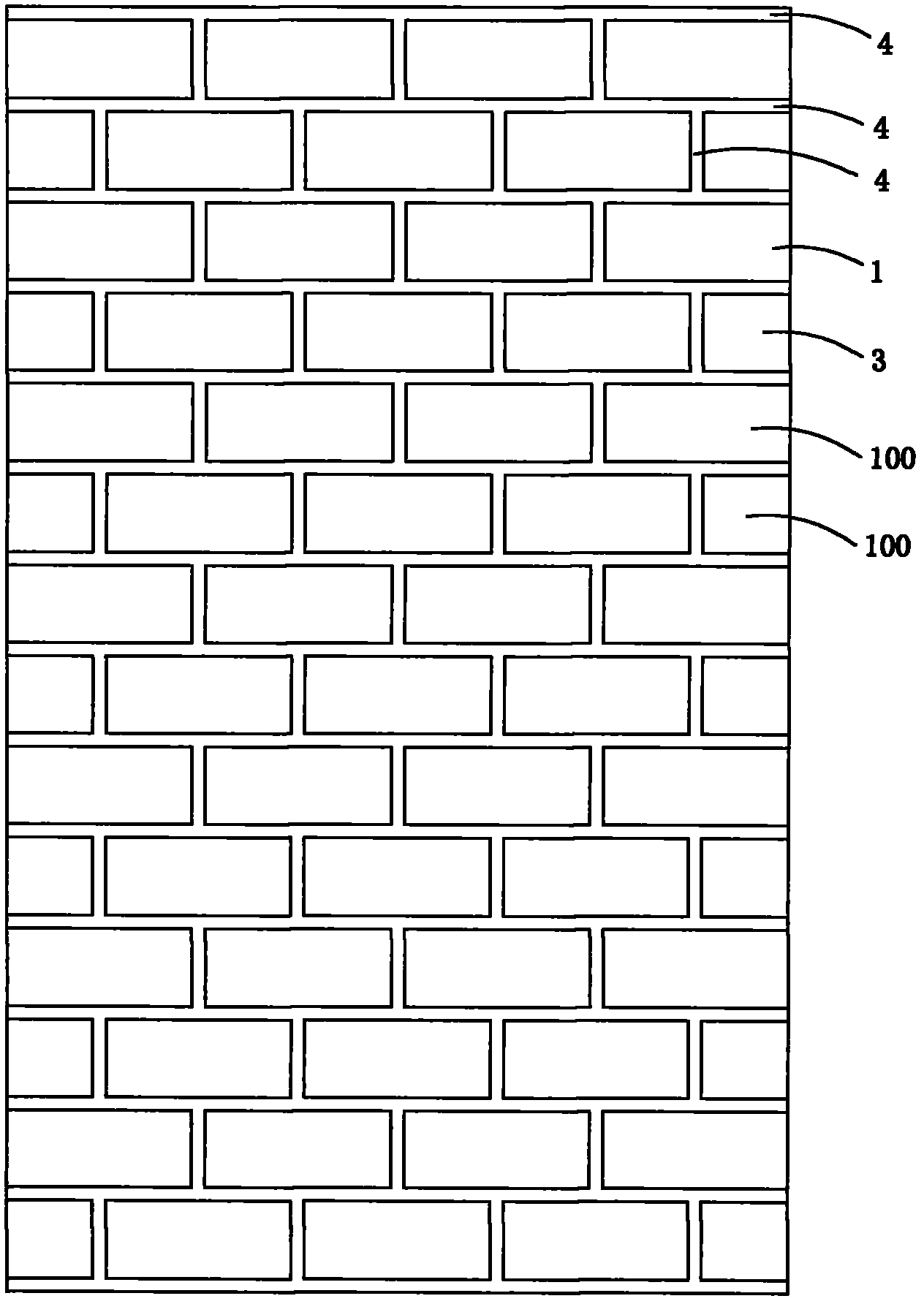

[0031] figure 1 It is a structural schematic diagram of the shell of the non-metallic box-type substation in the present invention.

[0032] This embodiment is a non-metal box-type substation shell, the wall 1 of which is composed of a metal skeleton 2 and a non-metallic environmental protection cement composition wallboard 3 coated outside the metal skeleton 2, the wallboard 3 and the metal skeleton 2 bonding to form a whole; the outer wall of the wallboard 3 is provided with a rectangular protrusion 100 and a slot 4 located at the edge of the rectangular protrusion, and the combination of the rectangular protrusion 100 and the slot 4 forms a brick wall pattern .

[0033] The outer wall of the wallboard 3 is coated with a paint layer. The cross-sectional shape of each slot 4 is a semicircle.

[0034] The metal skeleton 2 is welded and connected by a plurality of steel bars 21, steel plates 22 are welded and...

Embodiment 2

[0036] (embodiment 2, exterior wall mould)

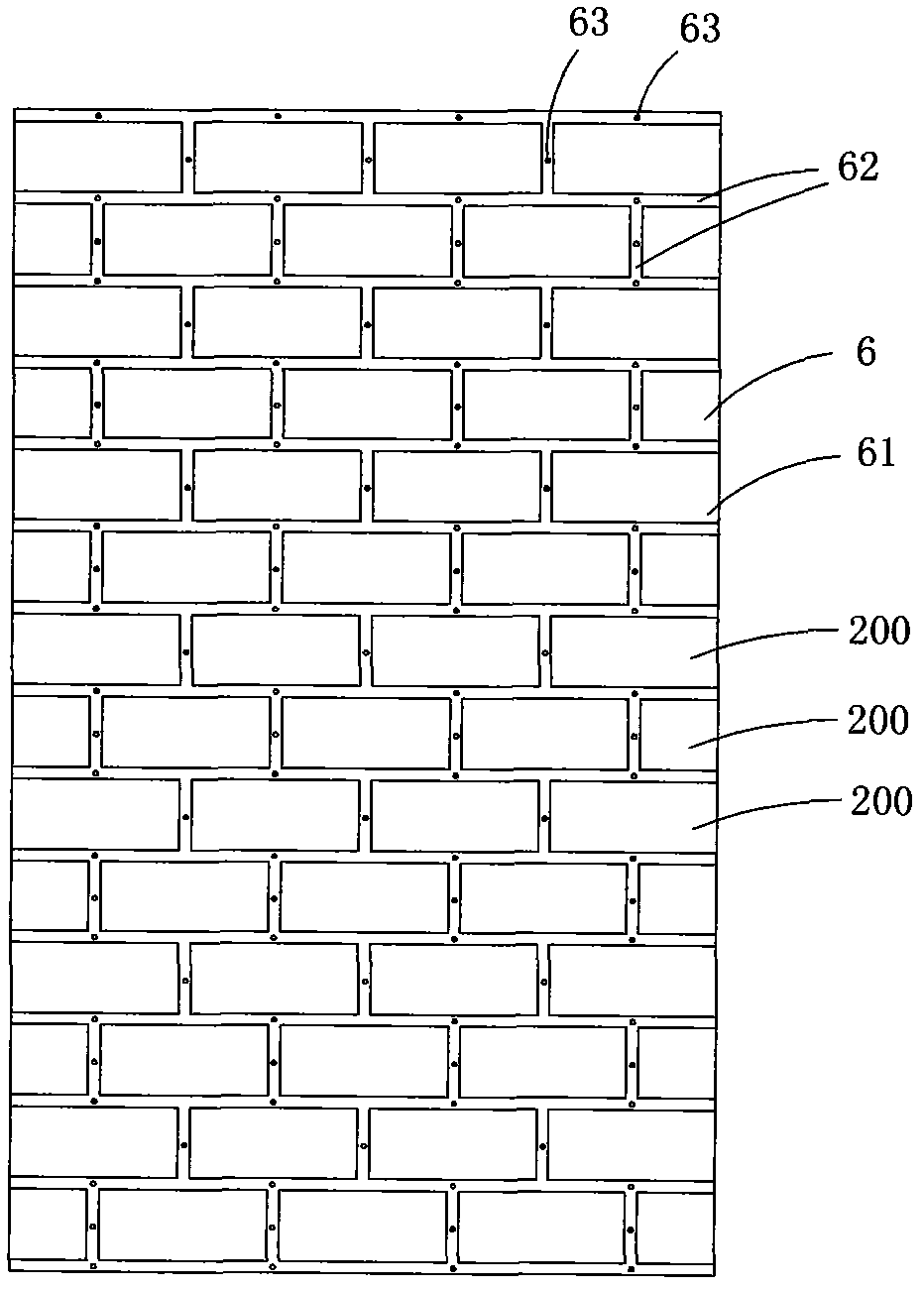

[0037] image 3 It is a structural schematic diagram of the exterior wall mold used in the process of the present invention.

[0038] This embodiment is an exterior wall mold for manufacturing non-metallic box-type substation shells, including a hard plate body 61, and the working surface of the plate body 61 is provided with a plurality of rectangular sections 200 to divide the working surface. Rib 62.

[0039] The cross-sectional shape of the protruding strip 62 is a semicircle.

[0040] In this embodiment, both the board body 61 and the protruding strips 62 are made of wood, and the protruding strips 62 are fixed on the board body 61 with screws or nails 63 .

[0041] In practice, the protruding strip 62 may also be glued and fixed on the board body 61 .

[0042] The structure of the external wall grinding tool in this embodiment is relatively simplified, especially the board body is made of wood and the raised strips for for...

Embodiment 3

[0043] (embodiment 3, the processing method for manufacturing non-metallic box-type substation housing)

[0044] Figure 2 to Figure 4 A specific embodiment of the process of the present invention is shown, wherein figure 2 It is a structural schematic diagram of the casting frame used in the process of the present invention; image 3 It is a schematic diagram of the structure of the external wall mold used in the process of the present invention; Figure 4 It is a structural schematic diagram of the metal skeleton used in the process of the present invention.

[0045] This embodiment is a process for manufacturing non-metallic box-type substation shells, see Figure 2 to Figure 4 , including the following steps:

[0046] ① Prepare the casting frame 5, the metal skeleton 2, and the exterior wall mold 6; the exterior wall mold 6 includes a hard plate body 61, and the working surface of the plate body 61 is provided with convex strips 62 arranged in a brick wall pattern; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com