Ceramic gas discharge metal halide lamps with high color temperature

A metal halide, gas discharge technology, used in gas discharge lamps, gas discharge lamp parts, discharge lamps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

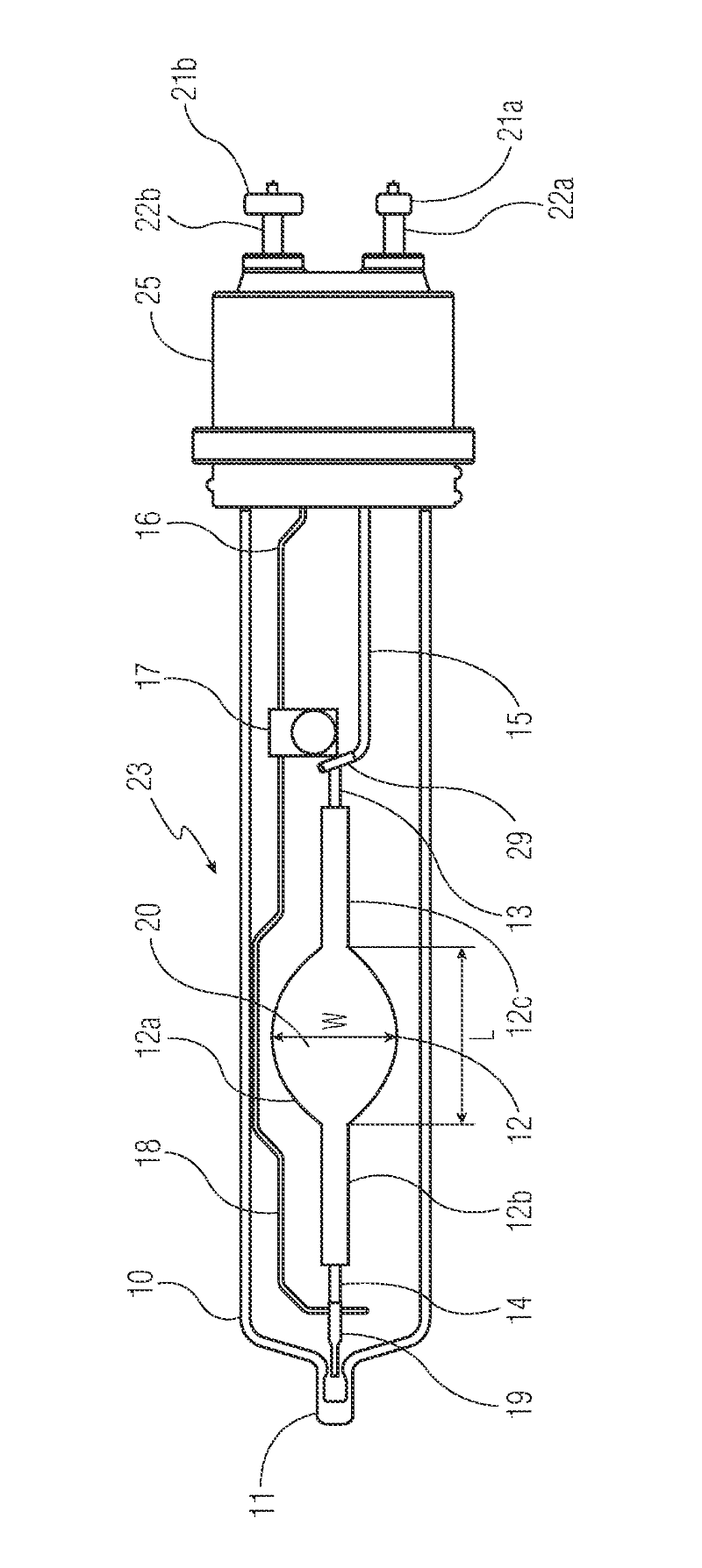

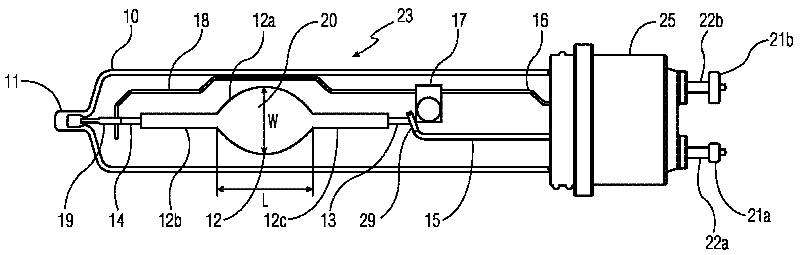

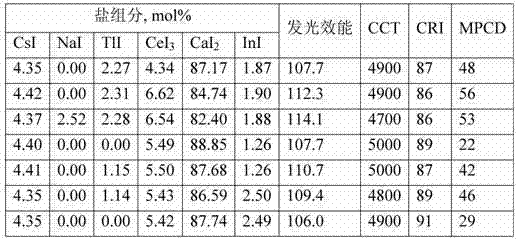

[0029] The arc tube was formed according to the shape shown in the drawing. The shape has a prolate spherical shape with a minor axis width W of approximately 18 mm and a major axis length L of approximately 26 mm. The wall thickness of the main body is about 1 mm. The end of the ball is integrally formed into a hollow axial extension through which the tungsten discharge electrode is inserted. The distance between the tungsten electrodes is 14mm. A dose of Hg is added to the arc tube as well as the salt mixture itself. The arc tube is filled with Ar, and a small amount of Kr is added 85 . The fill pressure was 75 Torr. Other inert gases such as Xe, Ne or a mixture of these gases can also be used for filling. The discharge electrodes are tightly sealed in extensions in the arc tube body.

[0030] The lamp was made with a rated power of 315W. The voltage of the lamp is about 100V, which is adjusted by the dose of Hg. The values of CCT, CRI and MPCD were measured after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com