Method for preparing pure rice flour bread and pure rice flour bread prepared by same

A production method and technology of rice flour, applied in baking, baked food, food science, etc., can solve problems such as inability to form gluten, inability to make leather, and unsatisfactory performance indicators, so as to increase gluten strength, improve performance indicators, and change gluten protein Effects on Structural Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

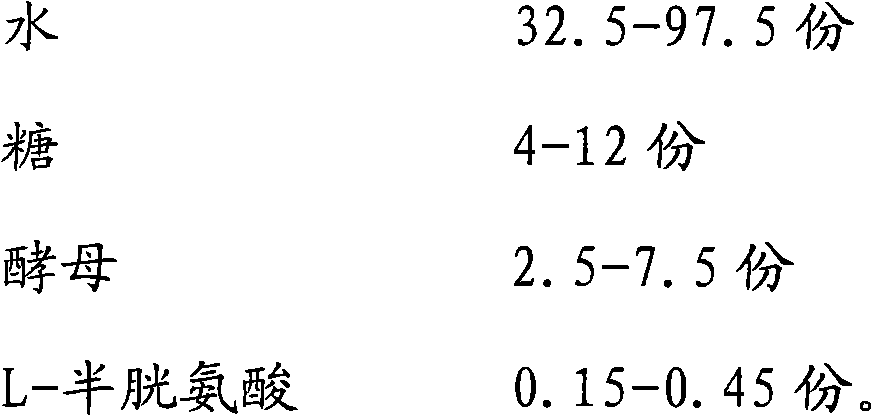

Method used

Image

Examples

Embodiment 1

[0028] Get fresh polished round-grained rice 3Kg, after soaking with clear water for 24 hours, organize a masher to mash initially, and then vertical cross-body mill grinds, and the prepared rice flour slurry is dried by a spray dryer to obtain rice flour, and the grain size of the gained rice flour is Number is greater than or equal to 75 orders; Add 0.015Kg additive in above-mentioned gained rice flour and mix evenly, the preferred additive of the present invention is L-cysteine, add 3Kg water after and stir, when stirring, first low-speed stirring (96r / min) 2min, Stir again at high speed (306r / min) for 3 minutes to make dough; cover the prepared dough with plastic wrap and let it stand for 12 hours to react. Increase the gluten strength of rice noodles when water is adjusted; add 0.25Kg of yeast and 0.4Kg of sugar to the mixture of 0.25Kg of water to dissolve, and then move it into the noodle tank together with the dough after standing reaction and stir at high speed (306r / m...

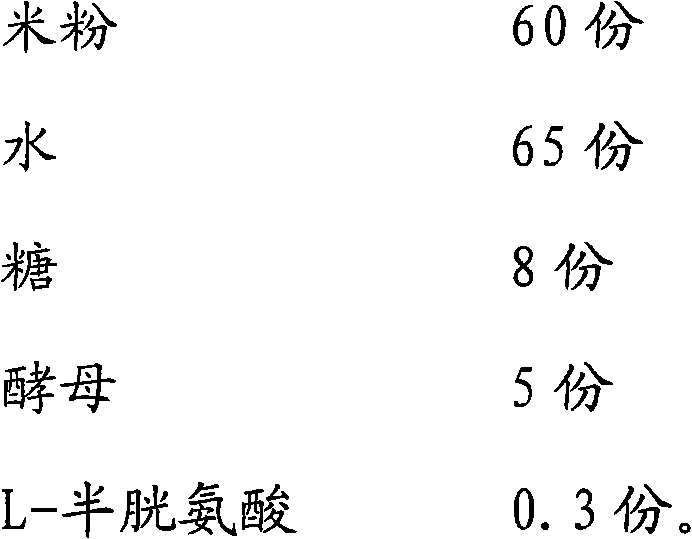

Embodiment 2

[0030] Get 6Kg of fresh round-grained rice, after soaking with clear water for 24 hours, organize a masher to mash initially, and then grind with a vertical cross-body mill, and the prepared rice flour slurry is dried by a spray drier to obtain rice flour, and the grain size of the gained rice flour is Number or be equal to 75 orders; Add 0.03Kg additive in the above-mentioned gained rice flour and mix evenly, the preferred additive of the present invention is L-cysteine, then add 6Kg water and stir, when stirring, first low-speed stirring (96r / min) 2min, then Stir at high speed (306r / min) for 3 minutes to make dough; cover the prepared dough with plastic wrap and let it stand for 12 hours to react. The gluten strength of rice flour when water is adjusted; after the mixture of 0.5Kg yeast and 0.8Kg sugar is dissolved in 0.5Kg water, it is moved into the noodle tank together with the dough after standing reaction and stirred at high speed (306r / min) for 3min until The dough is ...

Embodiment 3

[0032] Get 9Kg of fresh round-grained rice, after soaking with clear water for 24 hours, first organize a mashing machine to mash, and then grind with a vertical cross-body mill, and the prepared rice flour slurry is dried by a spray dryer to obtain rice flour. number or equal to 75 orders; in the above-mentioned gained rice flour, add 0.045Kg additive and mix evenly, the preferred additive of the present invention is L-cysteine, then add 9Kg water and stir, when stirring, first low-speed stirring (96r / min) 2min, then Stir at high speed (306r / min) for 3 minutes to make dough; cover the prepared dough with plastic wrap and let it stand for 12 hours to react. The gluten strength of rice flour when water is adjusted; after the mixture of 0.75Kg yeast and 1.2Kg sugar is dissolved in 0.75Kg water, it is moved into the noodle tank together with the dough after standing reaction and stirred at high speed (306r / min) for 3min until The dough is completely fused with the mixture of yeas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com