A kind of organic fiber reinforced organic airgel thermal insulation material and preparation method thereof

A technology of thermal insulation materials and organic fibers, which is applied in the field of organic fiber reinforced organic aerogel thermal insulation materials and their preparation, can solve the problems of hidden safety hazards, high equipment costs and operating costs, and achieves improved strength, excellent thermal insulation performance, The effect of low gas heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

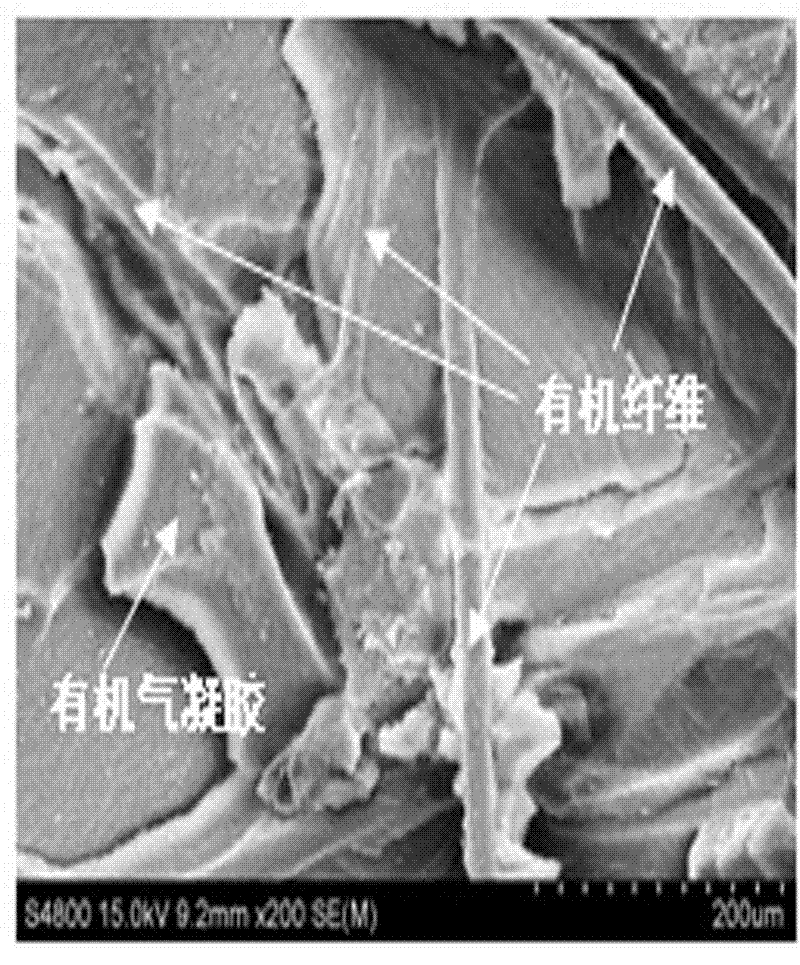

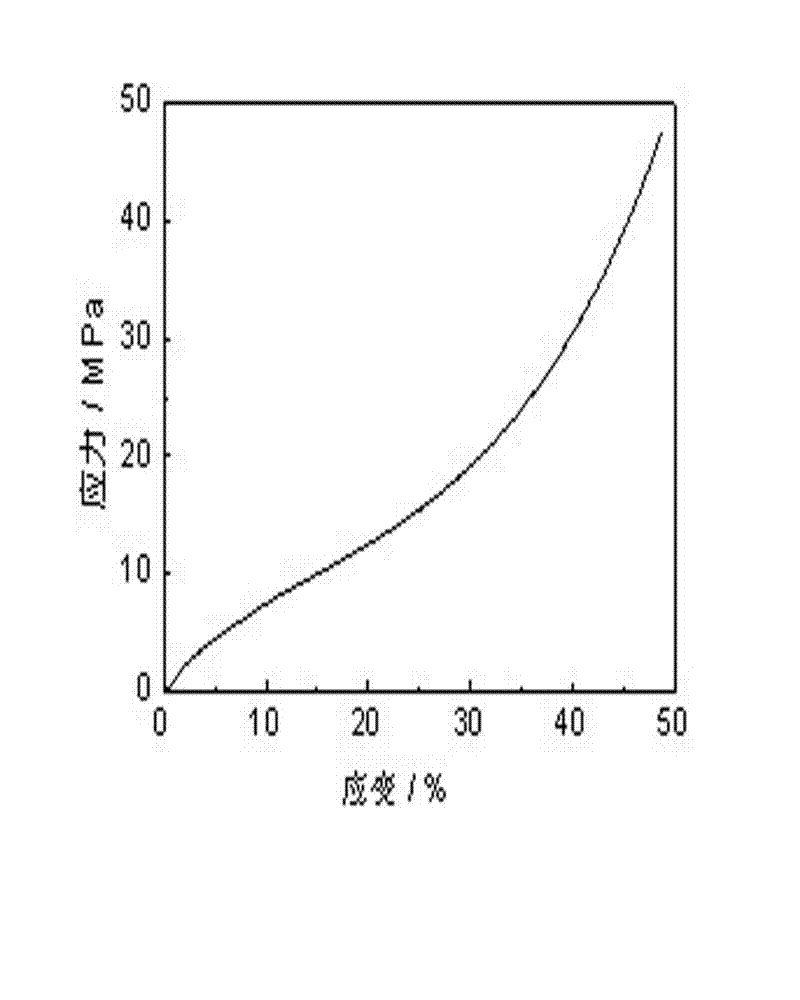

[0034] In this example, the organic fiber-reinforced organic airgel thermal insulation material product reinforcement is 26 μm polyacrylonitrile pre-oxidized silk fiber, the matrix is organic resorcinol-formaldehyde airgel, and the density is 0.473g / cm 3 .

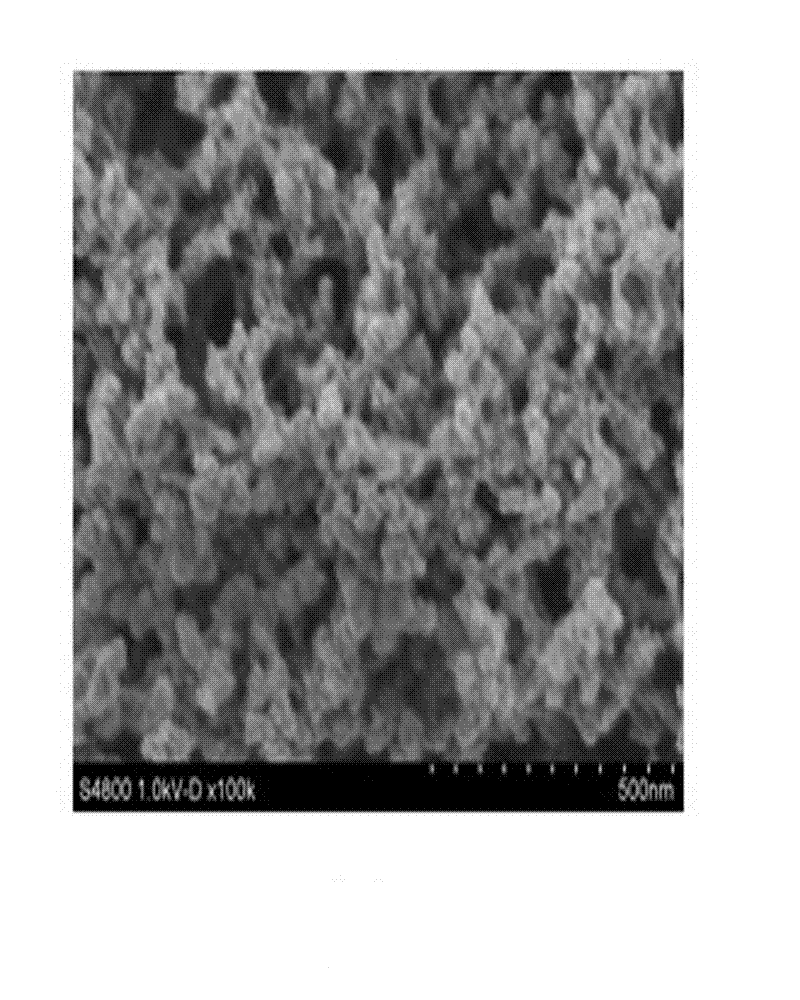

[0035] According to the molar ratio of raw materials resorcinol: formaldehyde: sodium carbonate: water = 1:2:0.001:16, prepare a solution of about 5L, stir for 30 minutes, then let it stand at room temperature for 1 day, and then vacuum impregnate the polyacrylonitrile base Pre-oxidized fiber preform, fiber preform apparent density 0.16g / cm 3 , the vacuum degree is 0.0095MPa when vacuuming, then put it in a 50°C water bath for 1 day, then raise the temperature of the water bath to 95°C, keep the temperature constant for 2 days, and then immerse the gel / fiber composite in 3 times its volume of ethanol ( 99.7%), continue to 50°C water bath, replace ethanol once every 24 hours, and replace 3 times in total, then take it ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com