Method for separating and purifying tetrandrine and tetrandrine from tetrandrine

A technology for tetrandrine and tetrandrine, applied in the chemical industry, can solve the problems of inability to meet market demand, small production scale, low product purity, etc., and achieve the effects of shortening separation time, saving reagents, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 100g of pulverized Fangji medicinal material, add 0.5L 50% ethanol, heat and reflux for 100 minutes, separate the residue and extract; add 0.5L 50% ethanol to the residue and reflux twice, each time for 60 minutes, separate the residue and extract; combine the extracts obtained by the above-mentioned reflux for 3 times, and recover ethanol by distillation under reduced pressure to obtain the crude extract of Fangji.

[0028] Dissolve the extract of Fangji crude extract with 0.2L of 0.5% hydrochloric acid, let it stand for 36 hours, and filter to remove the precipitate to obtain a solution; adjust the pH of the above solution to 8 with ammonia water, let it stand for 24 hours, then filter to obtain a precipitate, and let the precipitate dry in the air dry to obtain the crude extract of Fangji alkaloid.

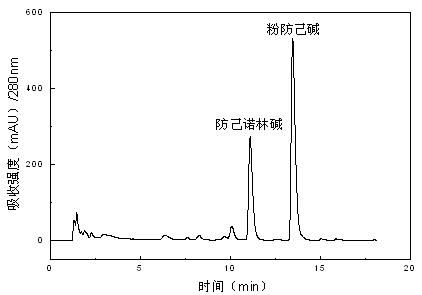

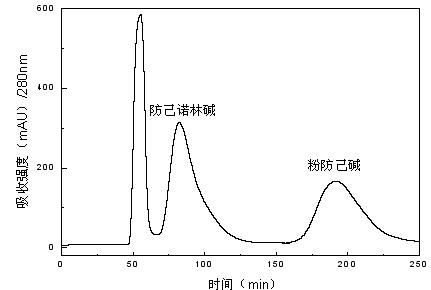

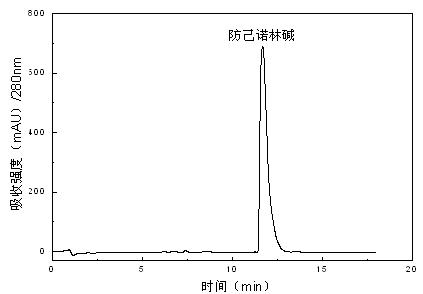

[0029] Diethyl ether-phosphate buffer was used as a high-speed countercurrent chromatography two-phase solvent system to separate and purify the extract of Fangji. ...

Embodiment 2

[0031] Take 100g of pulverized powdered Tetragalus, add 2L of 55% ethanol, heat and reflux for 90 minutes, separate the residue and extract; add 1L of 55% ethanol to the residue and reflux twice, each time for 50 minutes, separate the residue and extract liquid; the above-mentioned 3 times of reflux obtained extracts were combined, the ethanol was recovered by distillation under reduced pressure, and the crude extract of tetrandrine was obtained.

[0032]Dissolve the extract of Fangji crude extract with 0.16L of 1.0% hydrochloric acid, let it stand for 36 hours, and filter to remove the precipitate to obtain the solution; adjust the pH of the above solution to 10 with ammonia water, let it stand for 36 hours, then filter to obtain the precipitate, and let the precipitate dry in the air dry to obtain the crude extract of Fangji alkaloid.

[0033] Diethyl ether-phosphate buffer was used as a high-speed countercurrent chromatography two-phase solvent system to separate and purify...

Embodiment 3

[0035] Take 100g of pulverized Fangji medicinal material, add 0.5L 60% ethanol, heat and reflux for 80 minutes, separate the residue and extract; add 0.5L 60% ethanol to the residue and reflux twice, each time for 50 minutes, separate the residue and extract; combine the extracts obtained by reflux for the above 3 times, and recover ethanol by distillation under reduced pressure to obtain the crude extract of tetrandrine.

[0036] Dissolve the extract of Fangji crude extract with 0.08L of 4.0% hydrochloric acid, let it stand for 12 hours, and then filter to remove the precipitate to obtain a solution; adjust the pH of the above solution to 8 with ammonia water, let it stand for 24 hours, then filter to obtain a precipitate, and let the precipitate dry in the air dry to obtain the crude extract of Fangji alkaloid.

[0037] Diethyl ether-phosphate buffer was used as a high-speed countercurrent chromatography two-phase solvent system to separate and purify the extract of Fangji. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com