Preparation method of alkylaluminoxane solution

A technology of alkylaluminoxane and alkylaluminum is applied in the field of preparation of metallocene, late transition metal cocatalyst alkylaluminoxane solution, which can solve the problem of lack of thermodynamic stability, reduced cocatalyst activity, hindering commercial application, etc. problems, to achieve the effect of facilitating storage and transportation, reducing losses, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

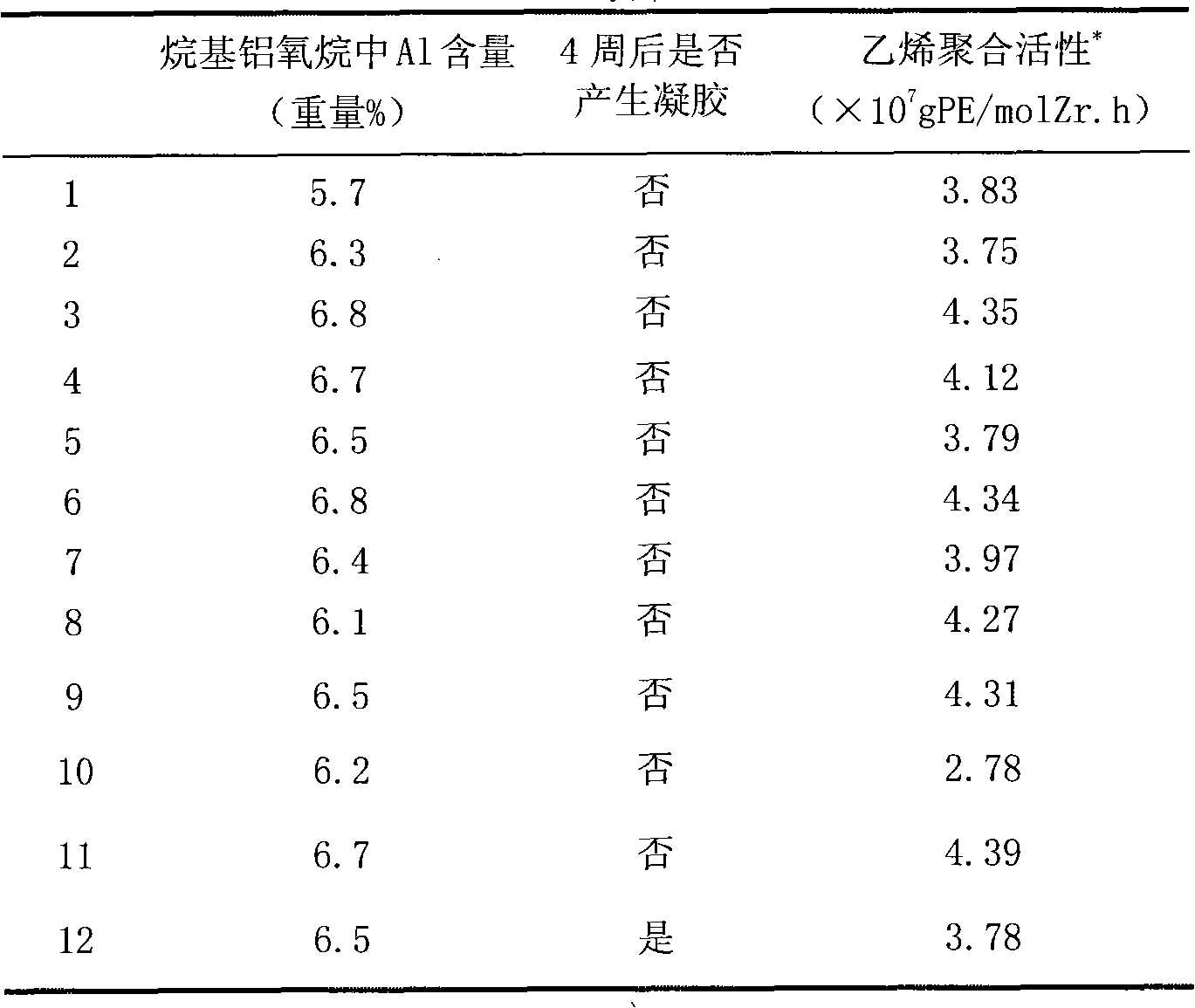

Examples

Embodiment 1

[0020] Under a nitrogen atmosphere, 100 milliliters of toluene was added to a 500 milliliter three-necked round-bottomed flask containing 23.7 grams of copper sulfate pentahydrate (about 0.474 moles of water) and 0.84 grams (about 0.035 moles) of anhydrous lithium hydroxide, and then 120 milliliters of 3 mol / liter trimethylaluminum toluene solution and 24 ml 3 mol / liter triisobutylaluminum toluene solution were mixed at room temperature, added dropwise to the flask for 1 hour, the reaction temperature was maintained at -10°C, and then continued to stir for 2 hour; add 15 milliliters of 2 mol / liter of diethylaluminum chloride in toluene, add dropwise within half an hour, and continue to stir for 1 hour. The solid material was removed by filtration to give a clear solution of the alkylaluminoxane in toluene.

Embodiment 2

[0022] Under a nitrogen atmosphere, 100 milliliters of toluene was added into a 500 milliliter three-neck round bottom flask containing 18.6 grams of magnesium chloride hexahydrate (about 0.542 moles of water) and 0.50 grams (about 0.021 moles) of anhydrous lithium hydroxide, and then 150 milliliters of 3 mol / liter trimethylaluminum toluene solution and 30 ml 3 mol / liter triisobutylaluminum toluene solution were mixed at room temperature, added dropwise to the flask for 2 hours, the reaction temperature was maintained at -15°C, and then continued to stir for 3 hours , and then add 12.5 milliliters of 2 mol / liter of a toluene solution of diethylaluminum chloride, the addition is completed dropwise within half an hour, and the stirring is continued for 1 hour. The solid material was removed by filtration to give a clear solution of the alkylaluminoxane in toluene.

Embodiment 3

[0024] Under a nitrogen atmosphere, 100 milliliters of toluene was added into a 500 milliliter three-necked round-bottomed flask containing 21.7 grams of aluminum sulfate octadecahydrate (about 0.586 moles of water) and 0.75 grams (about 0.031 moles) of anhydrous lithium hydroxide, and then 150 Mix a milliliter 3 mol / liter trimethylaluminum toluene solution and 30 milliliter 3 mol / liter triisobutylaluminum toluene solution at room temperature, add dropwise to the flask for 2 hours, keep the reaction temperature at -20°C, and then continue to stir 2 hours; 15.0 ml of 2 mol / liter toluene solution of diethylaluminum chloride was added, the addition was completed dropwise within half an hour, and stirring was continued for 1 hour. The solid material was removed by filtration to give a clear solution of the alkylaluminoxane in toluene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com