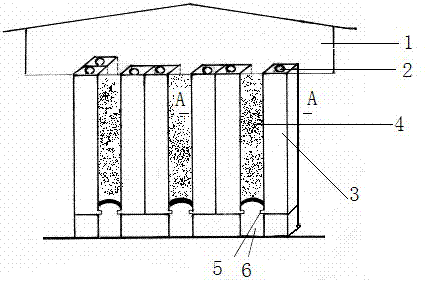

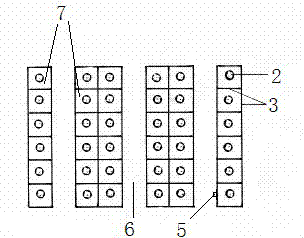

Underground bionic honeycomb granary

A bionic bee and granary technology, applied in climate change adaptation, agricultural buildings, building types, etc., can solve the problems of chemical pollution, large grain storage loss, large energy consumption, etc., and achieve easy and safe operation and compact structure , the effect of flexible texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

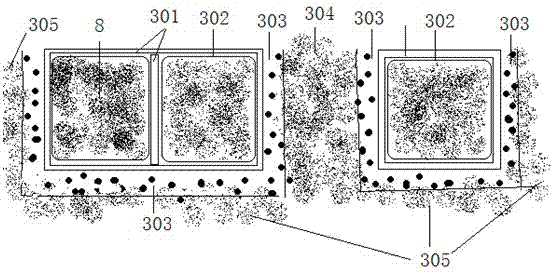

Method used

Image

Examples

Embodiment 2

[0069] A. Lay a polyethylene film in the silo before storing grain, place a film protector and a grain flow regulator in the polyethylene film at the grain storage outlet, pressurize and seal the polyethylene film outlet with a tightener, and close the Outlet sealing cap;

[0070] B. Use a grain conveyor to send the grain with moisture and impurities up to the standard into the polyethylene film from the upper mouth of the silo;

[0071] C. After the stored grain is loaded to the standard height, open the film opening until the grain temperature naturally dissipates below 20°C, discharge the air above the grain surface, pressurize and seal the upper opening of the polyethylene film with a tightener, and then seal it with a rubber pad. Cover the top of the silo.

[0072] The grains that meet the moisture and impurity standards are wheat, rice, beans and other grains that have been air-dried or other precipitation measures, the moisture content of the grain is not more than 13%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com