Floater-guided steam trap

A pilot-operated, steam trap technology, applied in the direction of steam traps, mechanical equipment, etc., can solve problems such as uneven wear, air blockage, increased friction, etc., to achieve a wide range of applicable working conditions, sensitive and reliable action, and improve the use of performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

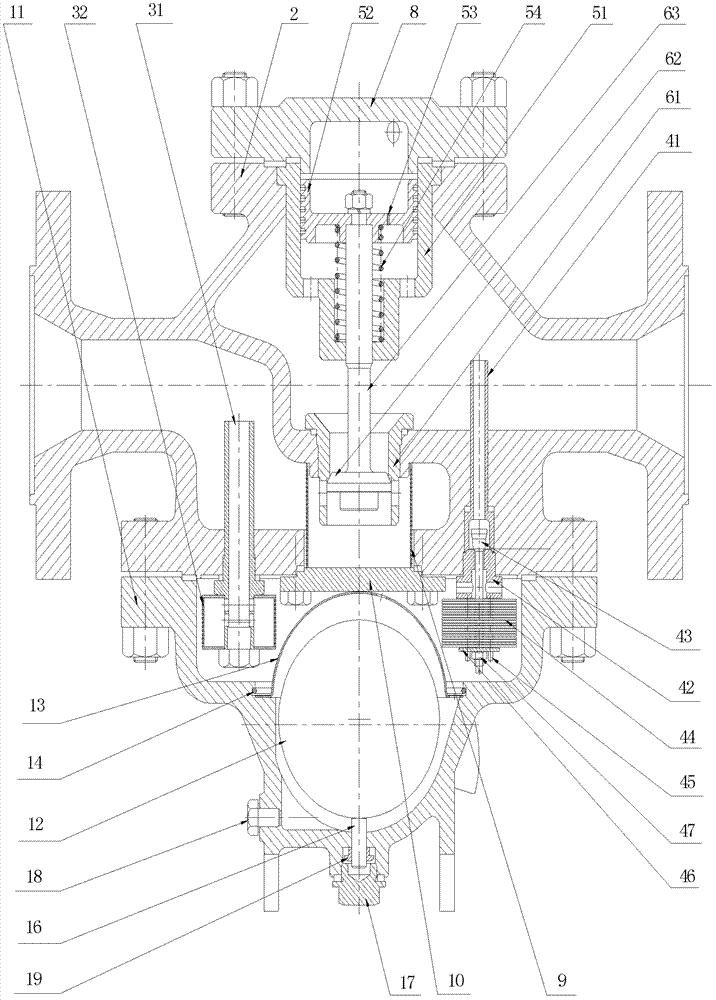

[0043] Embodiment 1 (float pilot type steam trap of bimetallic automatic air exhaust device)

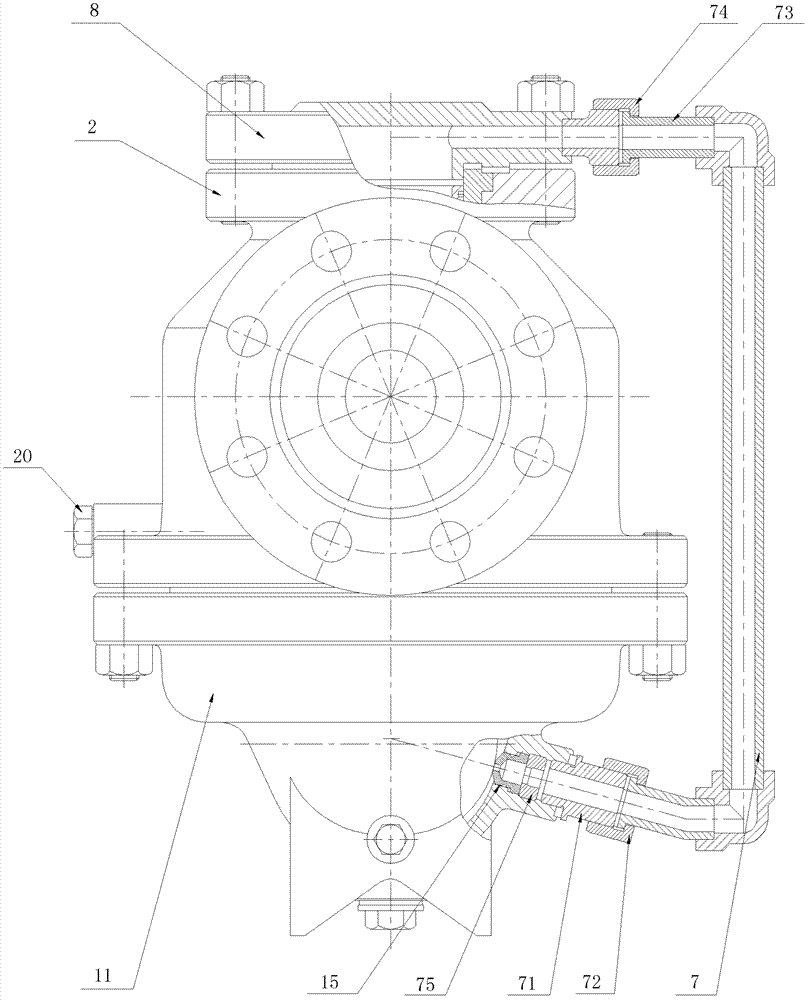

[0044] see figure 1 and 3 ~6, Embodiment 1 of the present invention is provided with a float pilot valve, an upper valve body 2, a filter device, an exhaust device, a piston assembly, a main valve, a conduit and a valve cover 8.

[0045] The floating ball pilot valve is provided with a lower valve body 11, a floating ball 12, a cover 13, a fixed circlip 14, a pilot valve seat 15, an adjusting bolt 16, a lower joint 71 and a blowdown bolt 18; the filtering device is provided with Inlet pipe 31 and filter screen 32; The piston assembly is provided with a piston body 51, a piston 52, three uniformly distributed pressure relief holes 53 and a spring 54; the main valve is provided with a main valve seat 61, a main valve core 62 And the main valve stem 63.

[0046] The upper valve body 2 and the lower valve body 11 are connected by stud bolts, and the upper valve body 2 and the lower va...

Embodiment 2

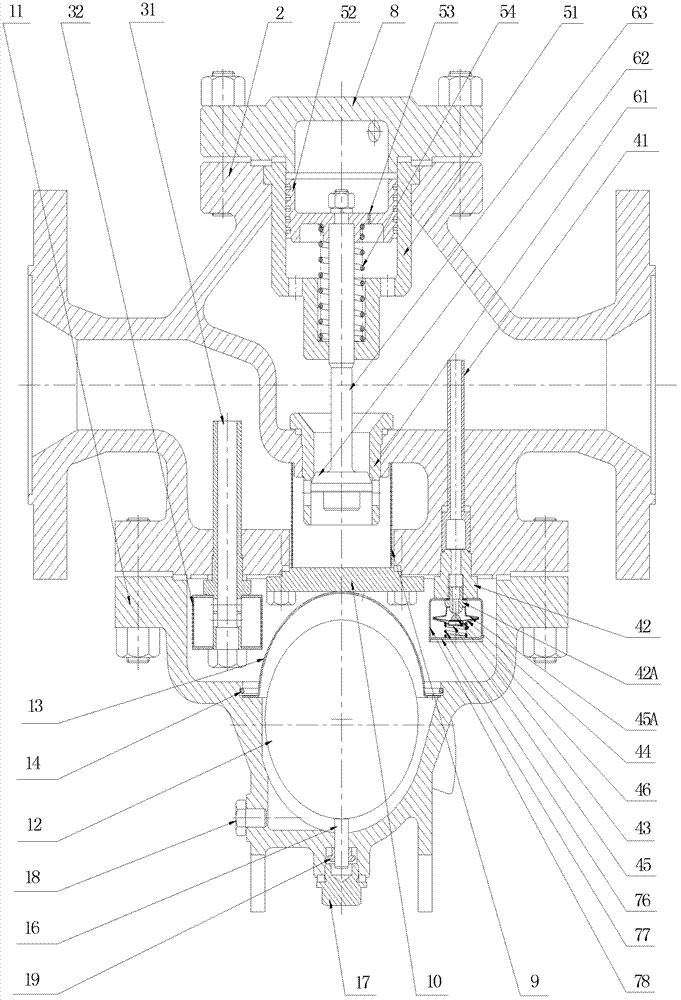

[0053] Embodiment 2 (float pilot type steam trap of the bellows automatic exhaust device)

[0054] see figure 2 and 7 , similar to Embodiment 1, the difference is that the exhaust device is provided with an exhaust pipe 41, a large exhaust valve seat 42, a small exhaust valve seat 42A, an exhaust valve core 43, a diaphragm 44, and a bellows upper cover 45, bellows lower cover 45A, limit plate 46, spring 76, pressure plate 77 and bellows cover 78, described exhaust pipe 41 is directly connected to the outlet cavity of upper valve body 2, exhaust pipe 41 is exhausted by large valve seat 42 Tighten, the exhaust small valve seat 42A and the large valve seat 42 are screwed and fixed, the upper cover 45 of the bellows box is welded together with the lower cover 45A of the bellows box and the diaphragm 44, the exhaust valve core 43 is connected with the diaphragm 44 and the limit plate 46 spot welding connection, the lower end hole of the bellows cover 78 is inserted into the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com