Method of Controlling Bottom of Roadway by Deep Hole Interval Blasting

A technology for roadway and deep hole, which is applied in the field of deep hole interval blasting control of roadway bottom, can solve the problems of deterioration, insufficient depth, and poor control effect of roadway bottom, and achieves the effect of maintaining stability and reducing the amount of bottom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0023] In this embodiment, a working face with a coal seam thickness of 3 m is taken as an example to introduce the treatment method for roadway undercut.

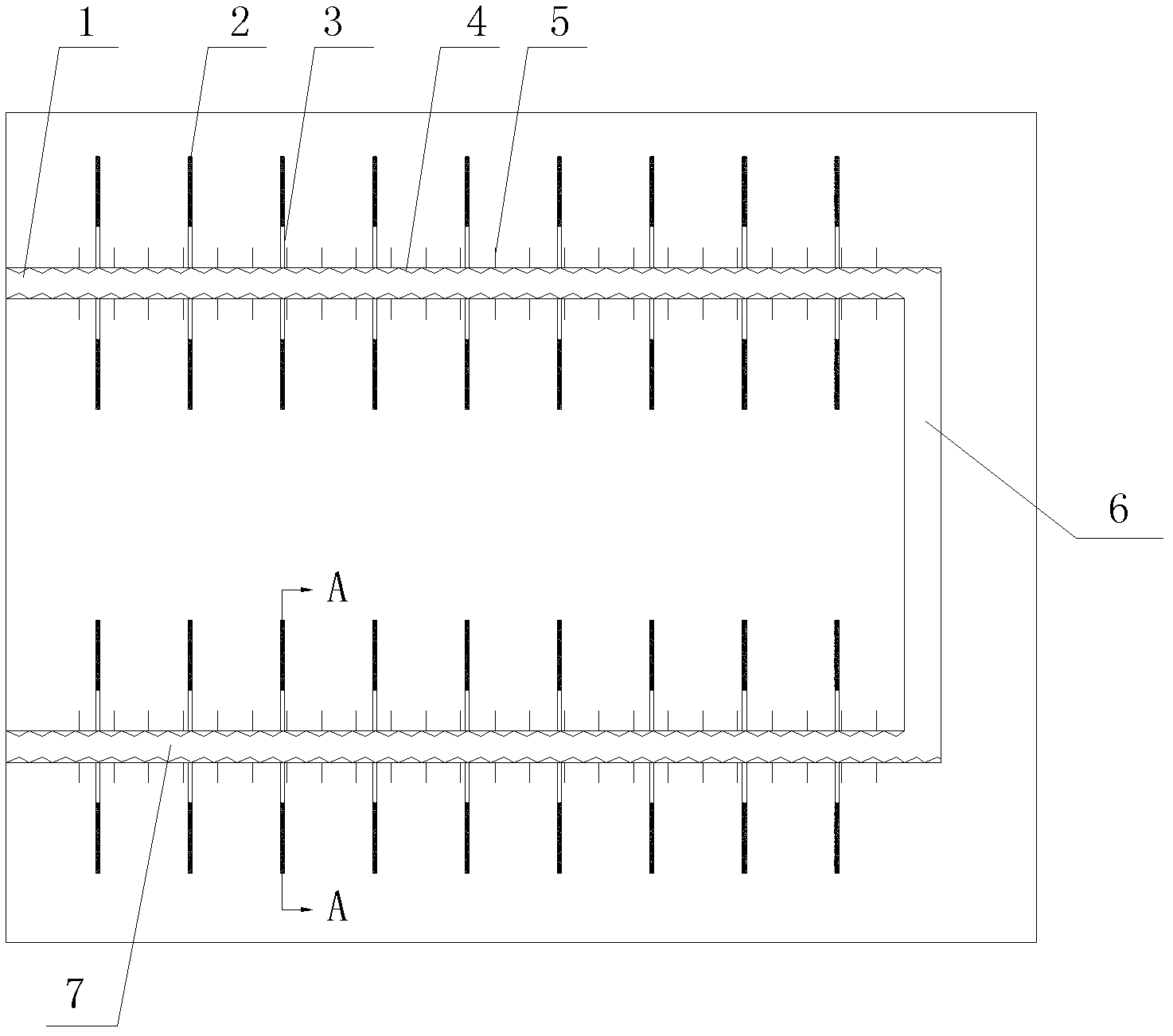

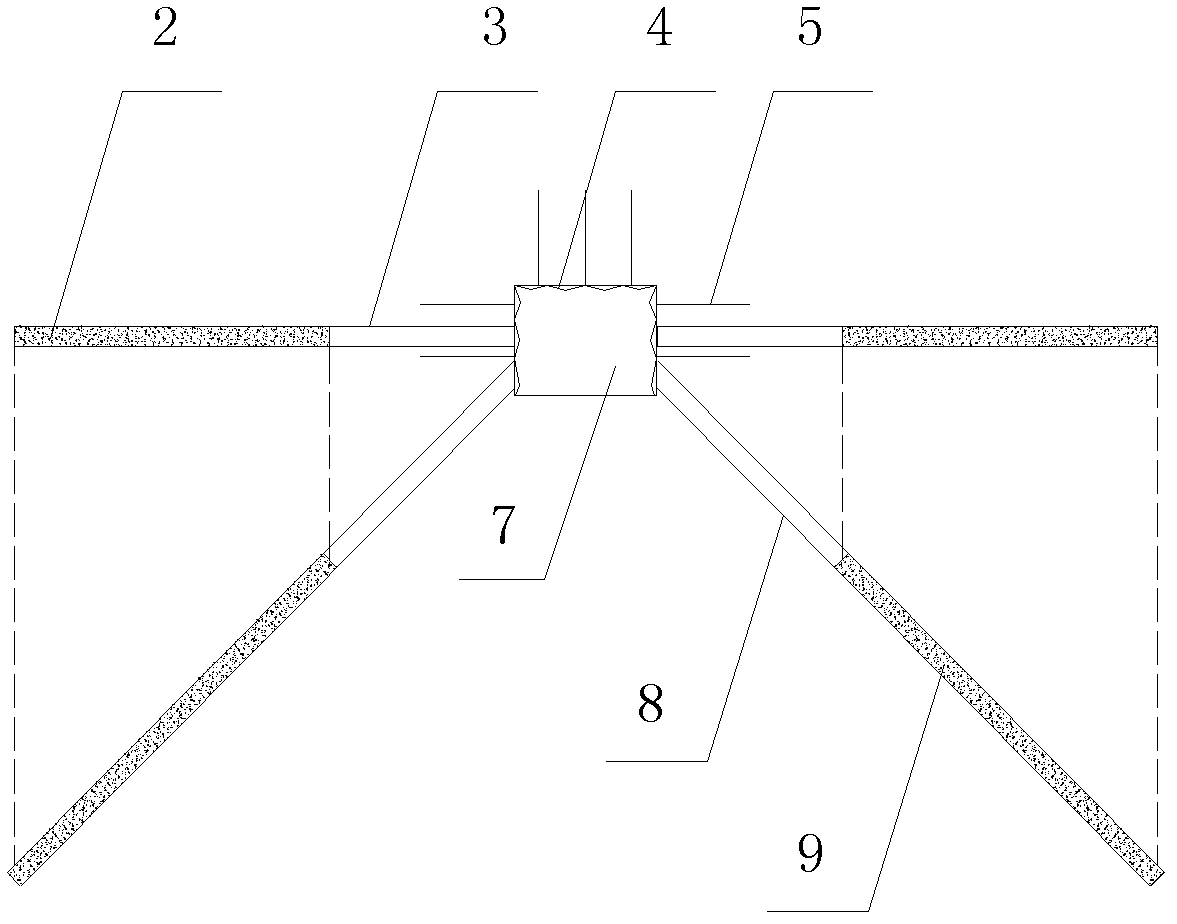

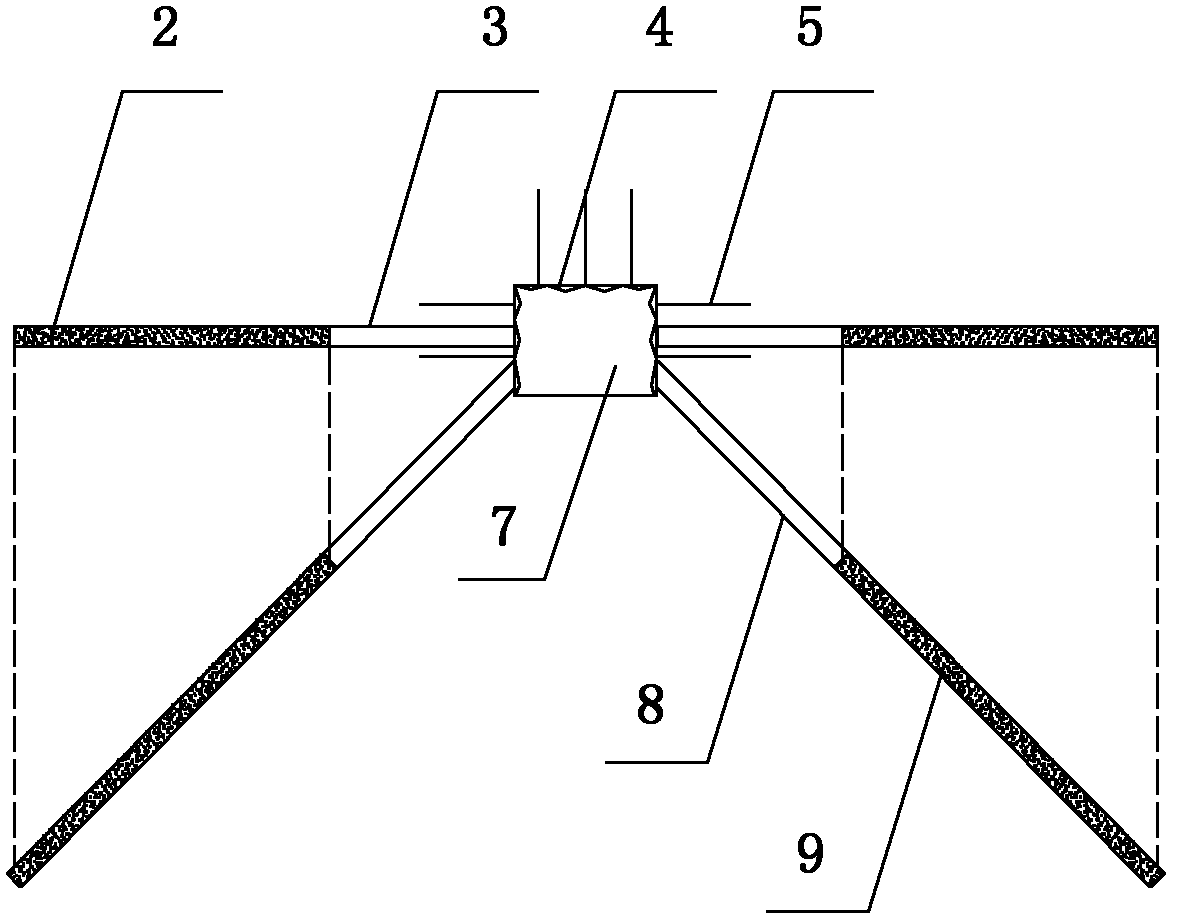

[0024] Such as figure 1 As shown, firstly, in the underground mining area, roadways such as inlet air entry 1, incision 6 and return air entry 7 are excavated in the underground mining area; Lay diamond-shaped metal mesh 4 on the top plate and the two sides of the return air alley 7, and the lap length between the nets is 100mm; the roof and the two sides after the netting are installed with an anchor rod 5 with a length of 2.5m, and the anchor rod The row spacing between 5 is 600mm×800mm.

[0025] After completing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com