A dual-channel hybrid ultrasonic flowmeter and its measuring method

A flow measurement and ultrasonic technology, which is used in the field of dual-channel dual-mode hybrid ultrasonic flowmeter and measurement, can solve the problems of high requirements for fluid to be measured, high requirements for moving impurity distribution, and difficulty in ensuring accuracy, and achieves improved accuracy, expanded Measuring range, effect of reducing flow velocity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

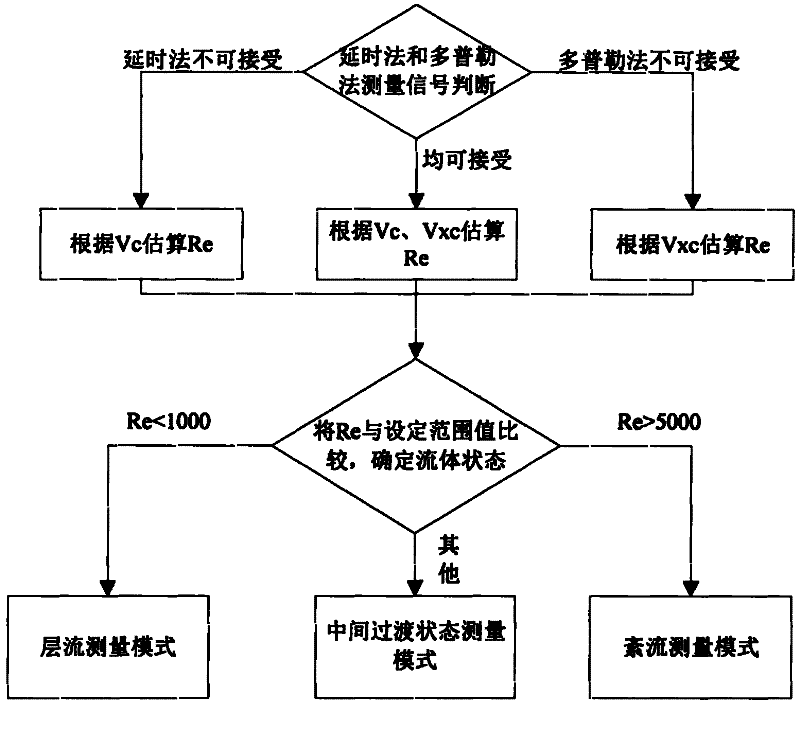

[0056] The main difficulty of the dual-channel hybrid ultrasonic flow measurement method of the present invention is that it is necessary to dynamically calculate the flow velocity distribution of the fluid. The flow velocity distribution is related to the fluid Reynolds number Re. Re is proportional to the flow velocity and pipe diameter of the fluid, and inversely proportional to the viscosity of the fluid, see Expression 1:

[0057] Re = ρ * V * D μ - - - ( 1 )

[0058] Among them, ρ is the fluid density, V is the average flow velocity of the fluid, D is the diameter of the fluid flowing through the pipe, and μ is the fluid viscosity.

[0059] When the Reynolds coefficient Re is less than 1000, the fluid is generally laminar flow, and when the Reynolds coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com