A Surface Defect Detection Method Based on Fusion of Gray Level and Depth Information

A technology of depth information and defect detection, which is applied in the direction of optical test defect/defect, image data processing, instrument, etc., can solve the problems of unreachable, undetectable, misidentification, etc., and achieve the effect of improving reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

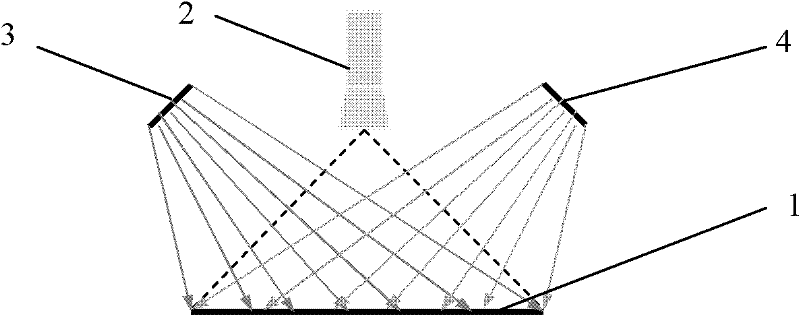

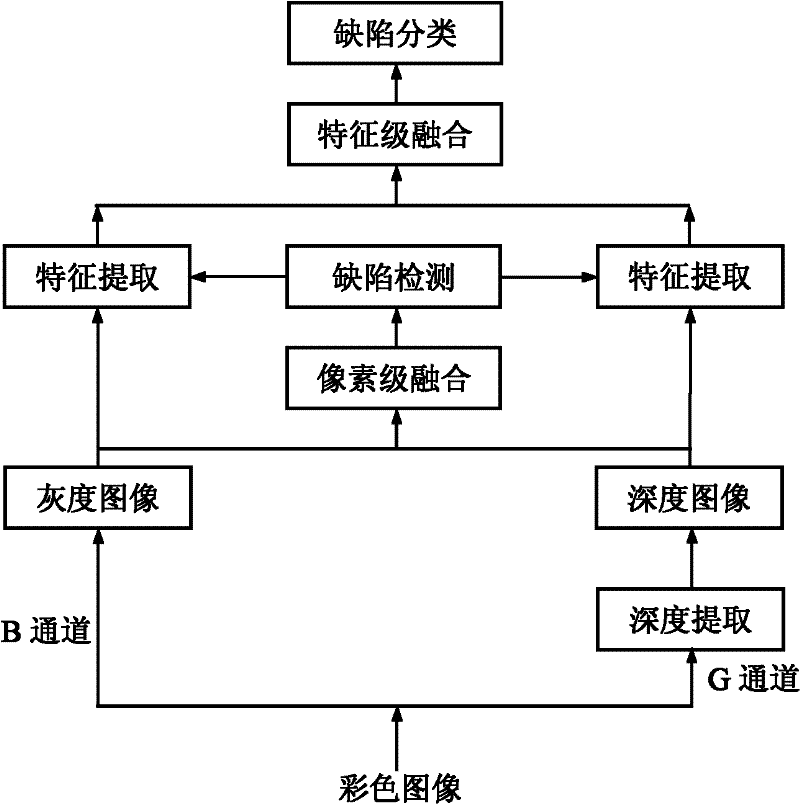

[0025] figure 1 Among them, the blue diffuse light source 3 and the green surface structured light source 4 irradiate the same area on the surface of the object 1 to be inspected, and the color area array CCD camera 2 collects images of the illuminated area on the surface of the object 1 to be inspected. In the color image collected by the camera 2, the blue channel (namely, the B channel) is the reflected light image irradiated by the light source 3 on the surface of the object 1, and the green channel (G channel) is the reflected light image irradiated by the light source 4 on the surface of the object 1 . Since the light source 3 emits diffuse light, the B channel image is the surface grayscale image of the object 1 . Since the light source 3 emits surface structured light, the G channel image is the surface structured light image of the surface of the object 1 . The surface structured light projection image also needs to undergo a depth extraction step before it can be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com