A method for measuring high temperature thermal conductivity

A technology of thermal conductivity and measurement method, applied in the field of high-temperature thermal conductivity measurement, can solve the problems of inability to achieve fast and accurate measurement of high-temperature thermal conductivity of thermal insulation materials, increase the difficulty and cost of testing, and large thermal conductivity measurement errors, and achieve high thermal conductivity. Practical application value, convenient measurement accuracy, accurate measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is described in further detail below by specific embodiments:

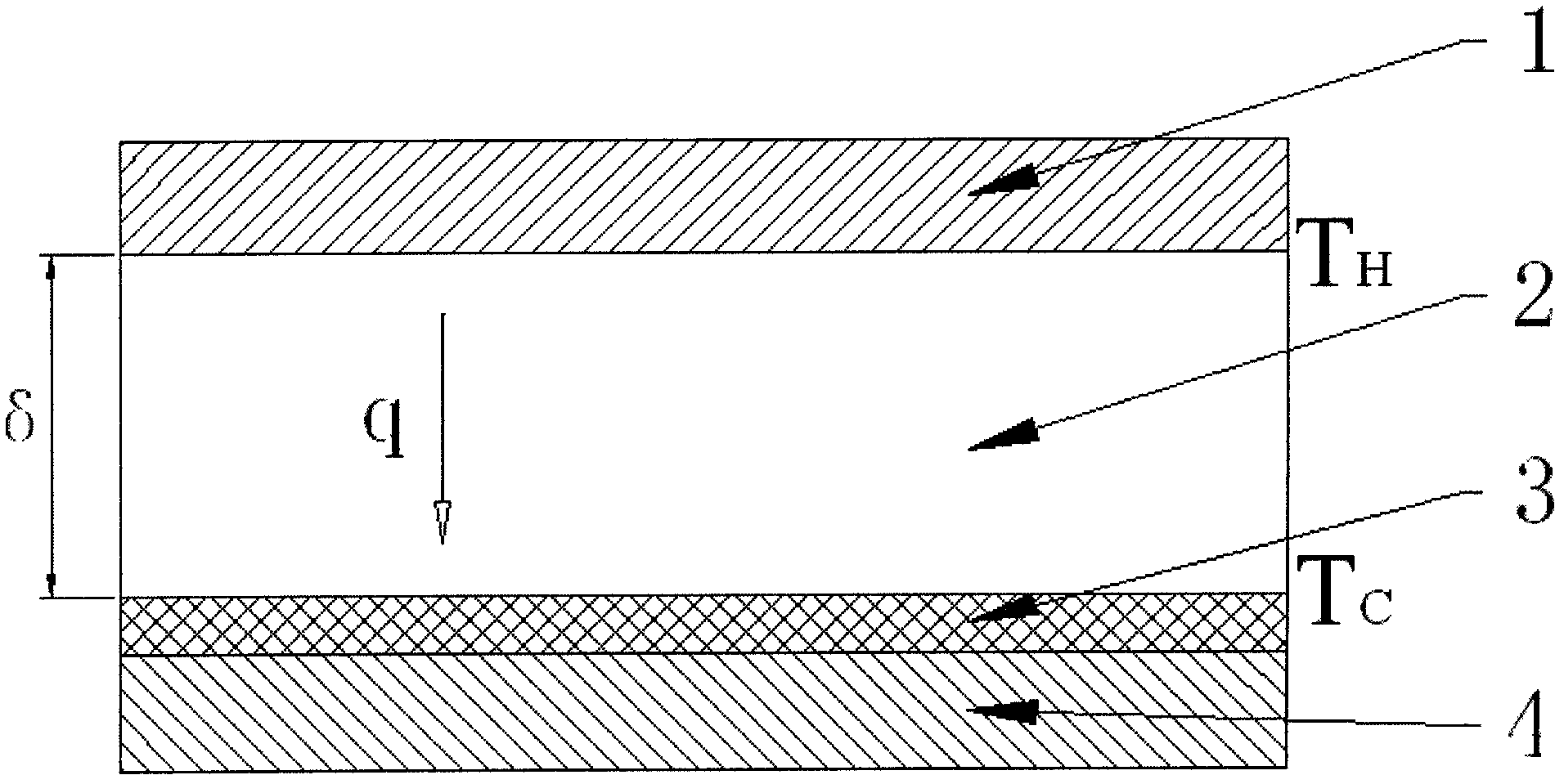

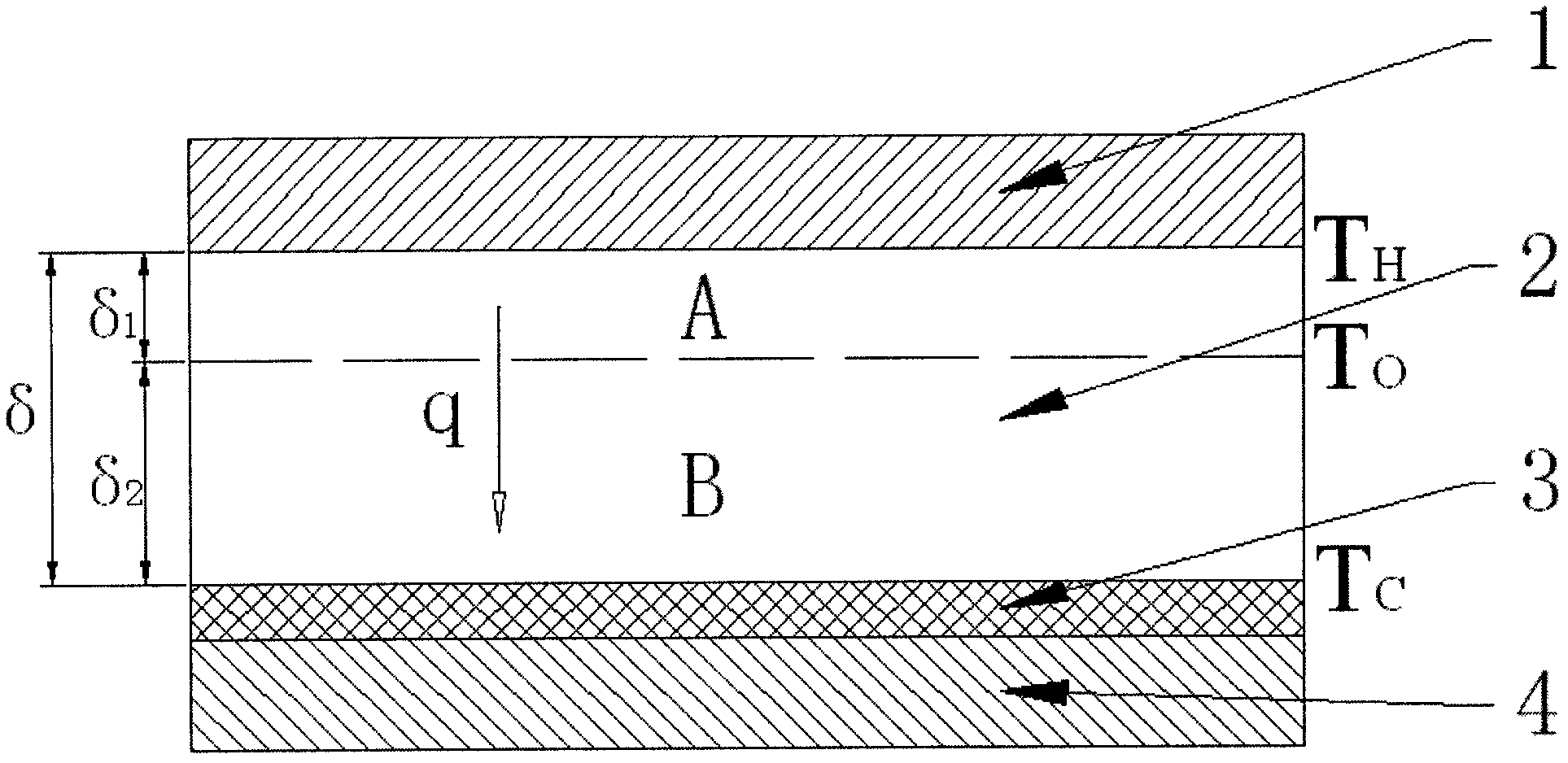

[0049] see figure 2 , which is a schematic diagram of the principle of the high-temperature thermal conductivity measurement method of the present invention. in accordance with figure 2 As shown, in the tested material sample, it is always possible to find the temperature T o material layer, and (T H +T C ) / 2o C . temperature is T o The material layer divides the material sample into two parts, A and B. Since it is a steady state heat transfer condition, the heat flux through part A of the material sample is equal to the overall heat flux q of the material sample. Due to the heat flux through part A of the material sample, and the T H , T o known, according to the formula

[0050] λ 2 = q δ 1 T H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com