A comprehensive water quality simulation test system for circulating pipe networks with visible pipe sections

A technology for simulating a test system and a circulating pipe, which is applied in the field of a comprehensive water quality simulation test system for a circulating pipe network, and can solve problems such as affecting the accuracy of flow control, insufficient condition control, and distortion of flow simulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

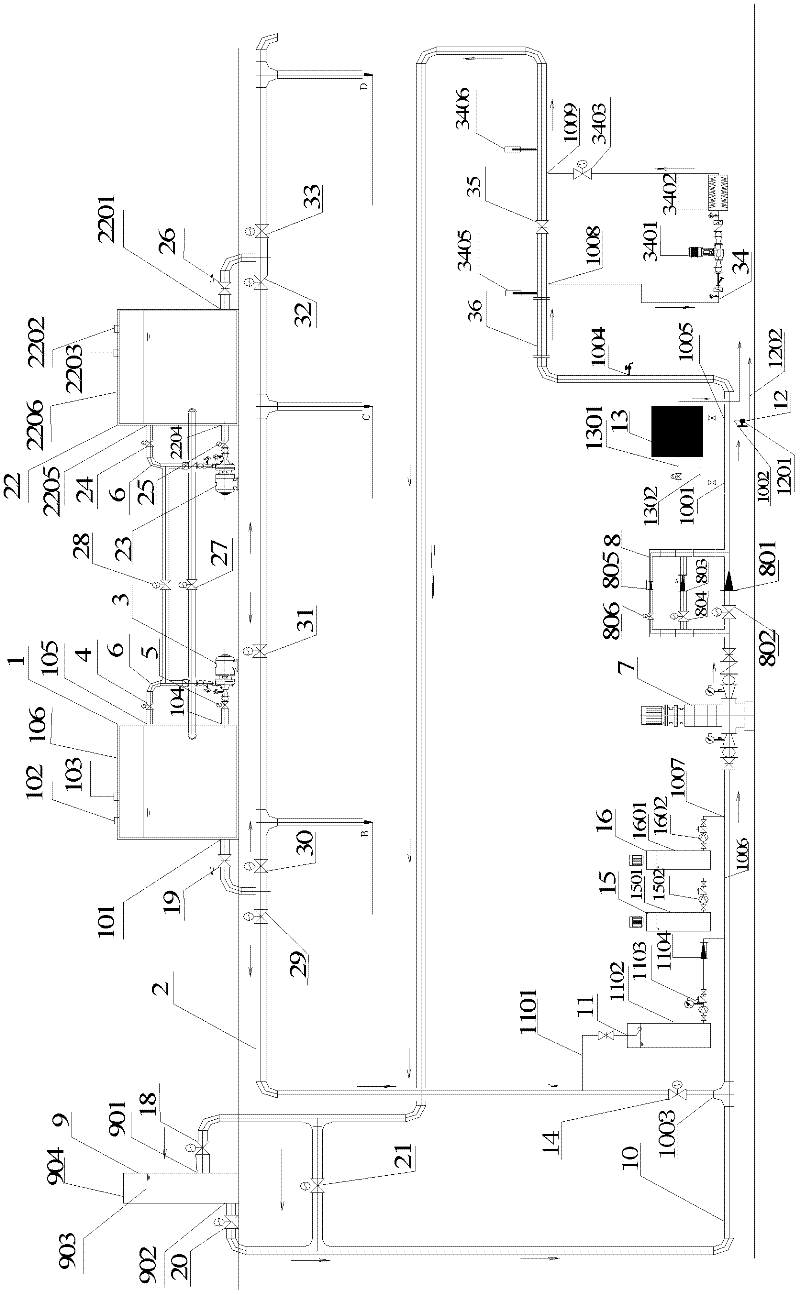

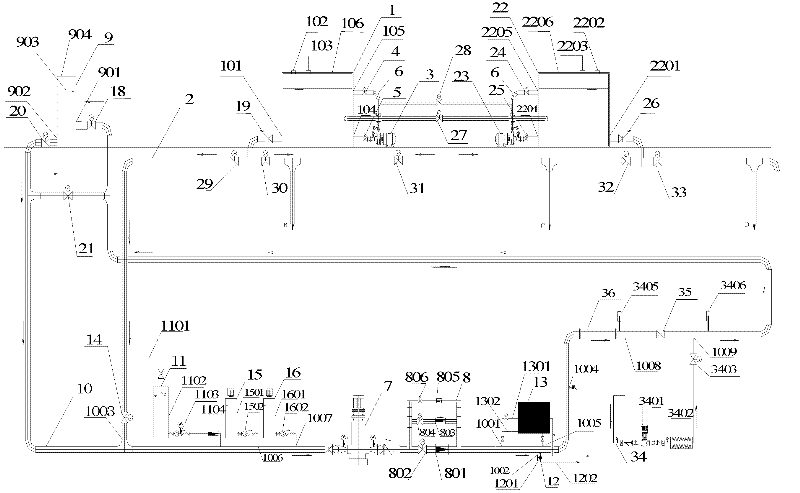

[0058] like figure 1 As shown, it is the comprehensive simulation test system for the water quality of the circulating pipe network with visible pipe sections of the present invention. Pipe network subsystem, the four independent circulation pipe network subsystems are the first independent circulation pipe network subsystem, the second independent circulation pipe network subsystem, the third independent circulation pipe network subsystem and the fourth independent circulation pipe network subsystem.

[0059] The water supply subsystem includes a first water supply tank 1, a second water supply tank 22, a pipeline 2, a first mixed circulation pump 3, a valve 4, a valve 5, a valve 19, a second mixed circulation pump 23, a valve 24, a valve 25, and a valve 26. , the second valve 27, the ninth valve 28, the valve 29, the valve 30, the valve 31, the valve 32, the valve 33 and the pipeline 6, the first water supply tank 1 is cylindrical, the volume is 6000L, the first water supply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com