Method, system and device for monitoring mechanical structural parts using rfid tags

A technology of RFID tags and mechanical devices, which is applied in the direction of connecting components, mechanical equipment, computer parts, etc., can solve the problems of expensive devices, many environmental resources, and the inability to be widely used, so as to improve safety, ensure personal safety, The effect of reducing the risk of omission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An RFID reliability monitoring system provided by Embodiment 1 of the present invention includes a reader and an RFID tag. The RFID tag includes a chip and an antenna element, and the antenna element has at least one breakable area. When the breakable area When broken, the RFID tag becomes useless.

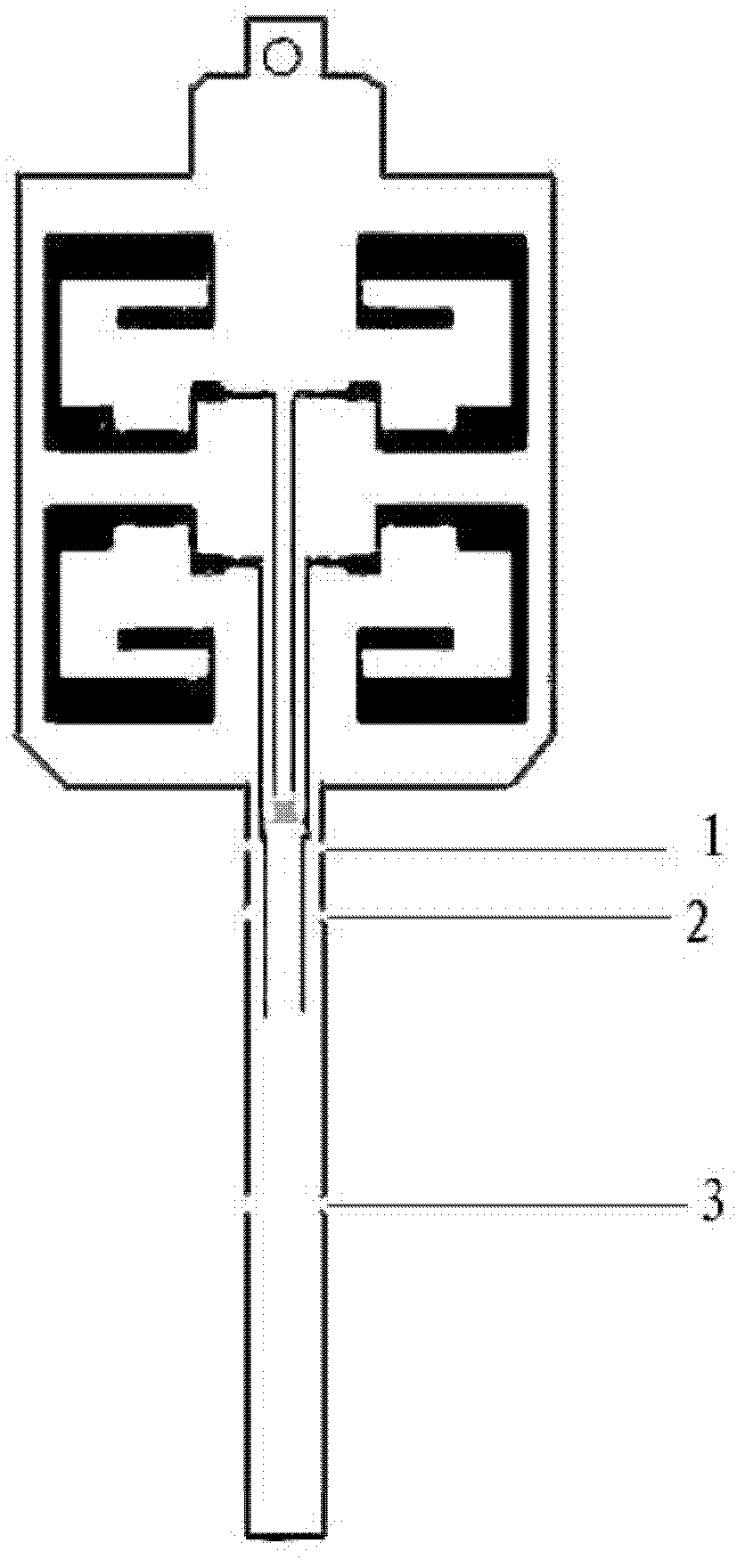

[0044] see figure 1 , shows a schematic structural diagram of the RFID tag in the RFID reliability monitoring system provided by Embodiment 1 of the present invention. figure 1 Also schematically shows the internal circuit structure of the RFID tag (as shown by the black area and lines inside the figure), figure 1 The antenna elements shown in are strip-shaped. Wherein, the positions of the notches indicated by the marks 1, 2 and 3 exemplarily show the positions of the three breakable regions on the antenna element.

[0045] The above-mentioned reader and chip adopt RFID reader and RFID chip, and the chip and the antenna element have a connected line. When there is an op...

Embodiment 2

[0049] Embodiment 2 of the present invention provides a mechanical device with an RFID reliability monitoring system. For the RFID reliability monitoring system, refer to the content in Embodiment 1. At least one breakable area of the RFID reliability monitoring system is fixed on the mechanical device At least one monitoring point that is prone to deformation or movement, when the monitoring point is deformed or moved, the breakable area breaks, and the RFID tag becomes invalid.

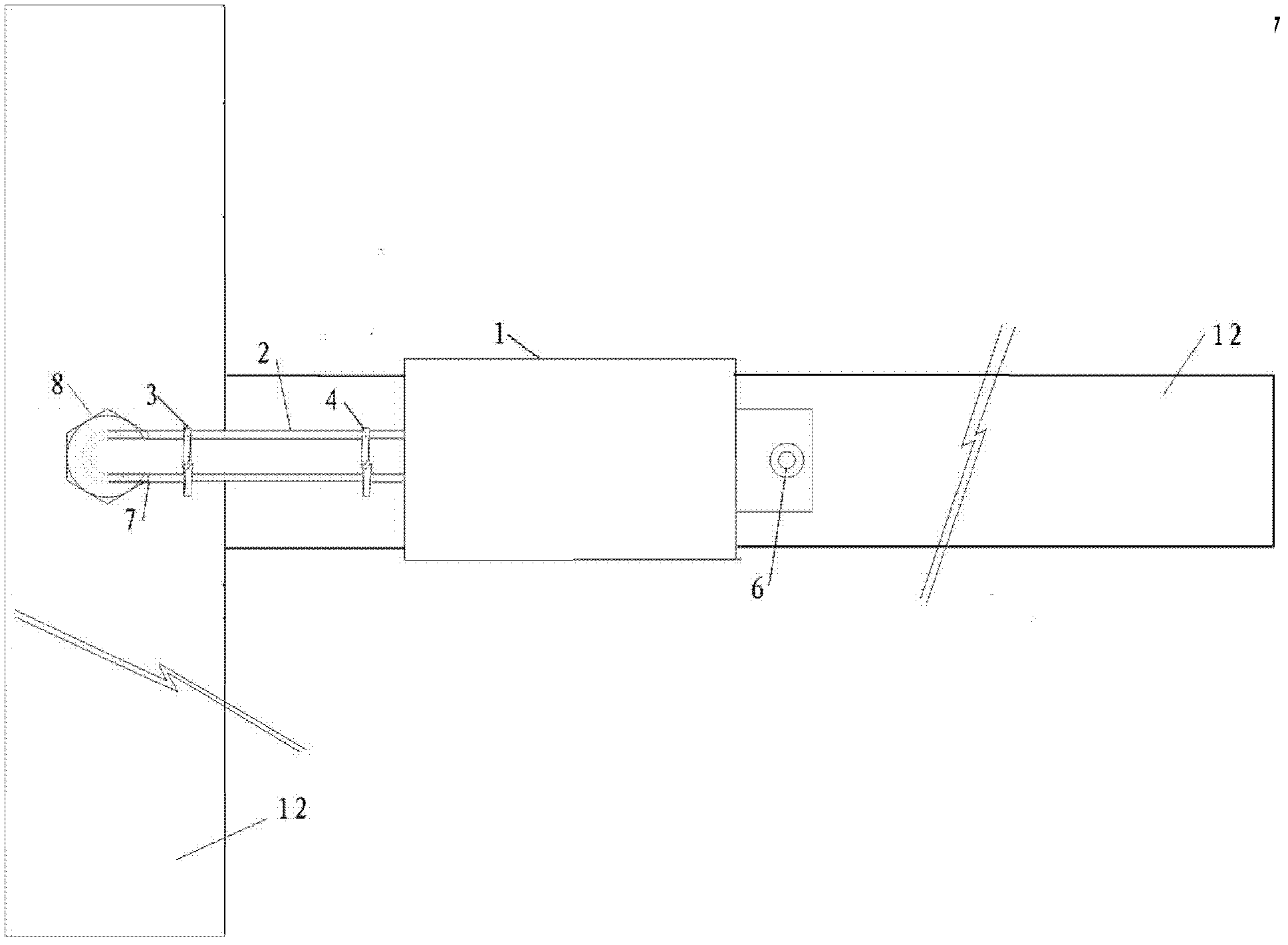

[0050] see figure 2 , showing a schematic partial installation of a mechanical device with an RFID reliability monitoring system. The RFID reliability monitoring system is connected to the bolt 8 at the joint of two steel pipes 12 on the mechanical device, such as through the welding point 7. The figure only schematically shows the local structure of the joint of the steel pipe 12. The zigzag mark indicates that part of the length of the steel pipe is omitted here or the part indicated by the ma...

Embodiment 3

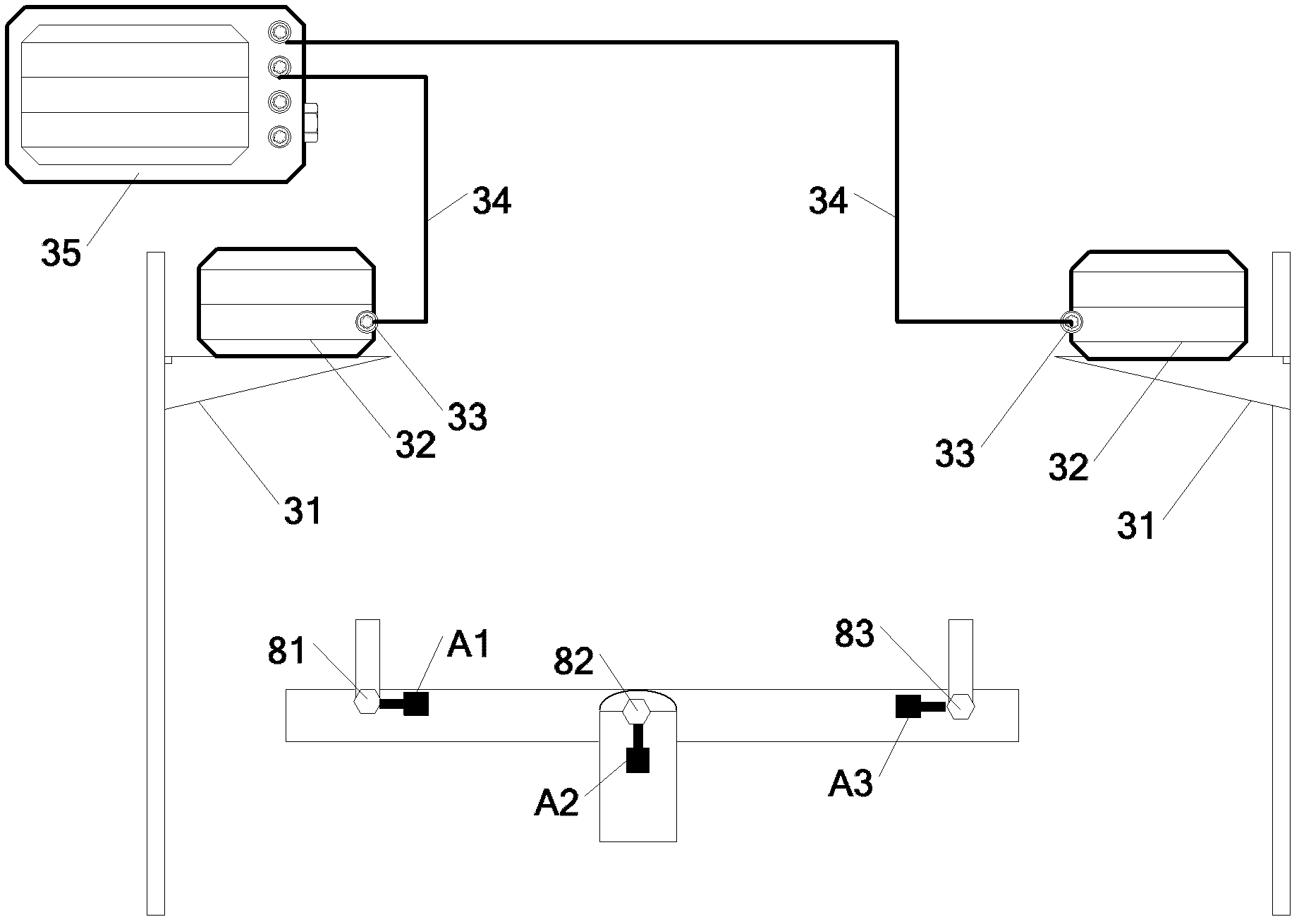

[0055] Embodiment 3 of the present invention provides a mechanical device with an RFID reliability monitoring system. For the RFID reliability monitoring system, refer to the content in Embodiment 1. At least one breakable area of the RFID reliability monitoring system is fixed on the mechanical device. At least one monitoring point that is prone to deformation or movement, when the monitoring point is deformed or moved, the breakable area breaks, and the RFID tag becomes invalid.

[0056] The above-mentioned mechanical device can be an independently operated device, or a certain part of an independently operated device. When the mechanical device is a certain part of an independently operated device, it can be installed on the device according to the characteristics of the device. Select different components to be monitored as the above-mentioned mechanical device, such as bolts, nuts, and the like.

[0057] The above-mentioned monitoring points that are prone to deformatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com