Magnetic block design method and magnetic block for a magnetic adsorption wall climbing robot

A technology of wall-climbing robot and design method, which is applied in the manufacture of manipulators, permanent magnets, inductors/transformers/magnets, etc., and can solve the problems of long cycle time, poor safety, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the accompanying drawings and examples.

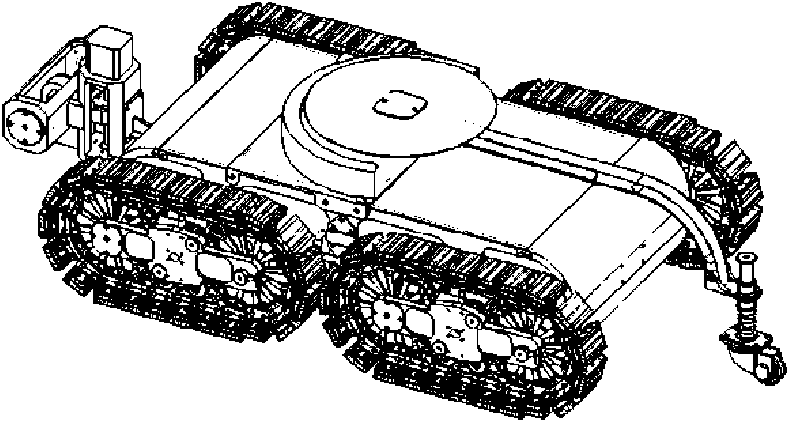

[0040] The wall-climbing robot involved in the present invention is as attached figure 1As shown, it has four crawlers, and magnetic blocks are installed on the outside of each crawler, so that the wall-climbing robot can crawl vertically and walk horizontally on inclined walls or even conical tower barrels. In this embodiment, the wall-climbing robot also has an anti-overturn bar that imitates the tail of a gecko. The anti-overturn bar is a bar that can rotate around a certain point on the back of the robot. The end of the bar that is not connected to the robot has casters in contact with the wall; when the robot head When tilting away from the wall, the casters at the end of the anti-tipping bar will be subjected to the force of the wall, and the force will be transmitted to the top of the anti-tipping bar by the anti-tipping bar, thereby counteracting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com