A square motor without casing

A technology without casing and stator core, which is applied in the direction of electromechanical devices, manufacturing motor generators, casings/covers/supports, etc., can solve the problems of motor performance deterioration, efficiency decline, copper consumption increase, etc., to achieve processing and Easy assembly, guaranteed concentricity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

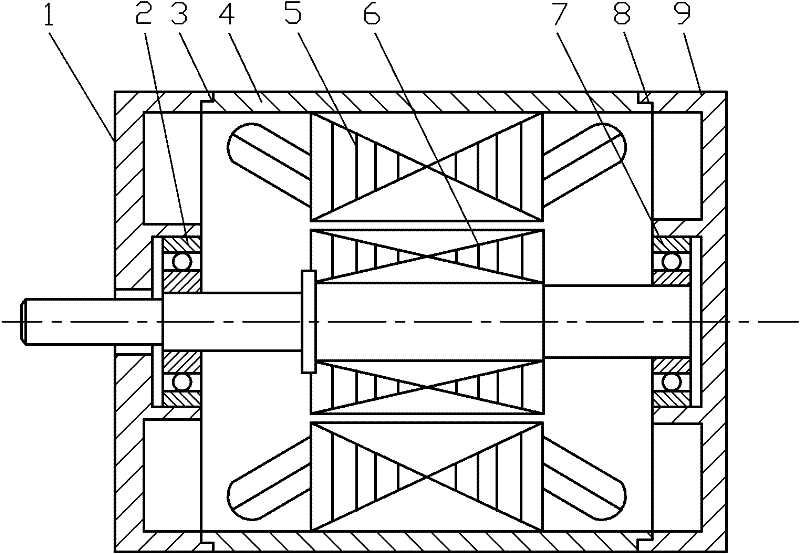

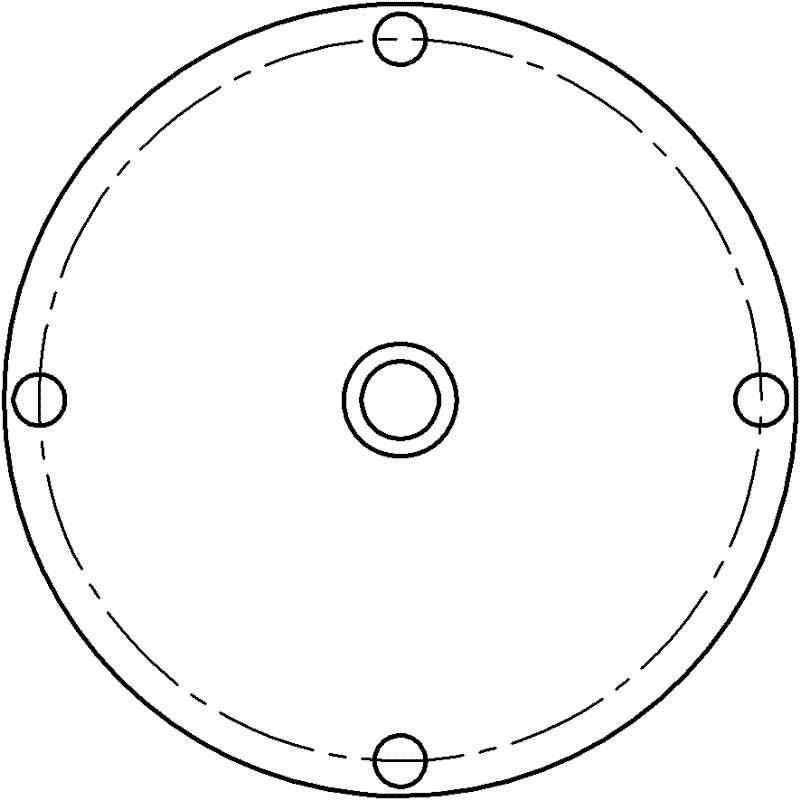

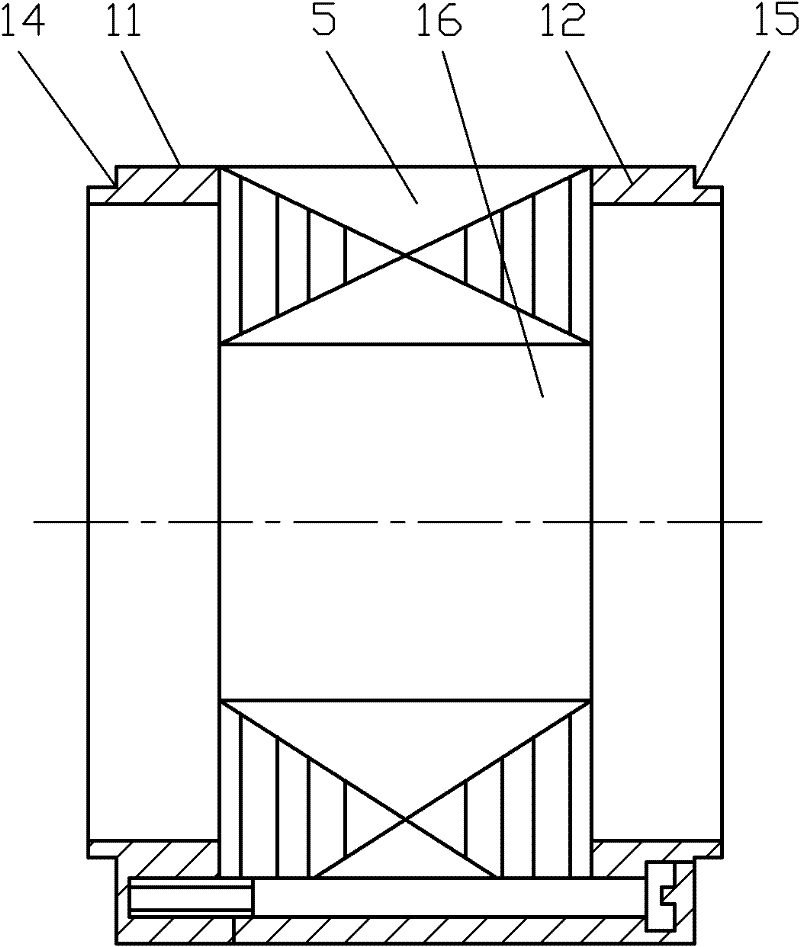

[0030] refer to Figure 7-Figure 12 , a casing-less square motor of the present invention includes a left end cover 1, a stator, a rotor 6 and a right end cover 9, and is characterized in that a small round hole 23 and a pin hole are provided on the four corners of the stator core 5 29. The left end cover 1 is provided with four screw holes 25 corresponding to the small circular holes 23 of the stator core 5 and four blind holes 24 corresponding to the pin holes 29 of the stator core 5; Four small round holes 22 corresponding to the small round holes 23 of the stator core 5 and four blind holes 26 corresponding to the pin holes 29 of the stator core 5 are provided on the right end cover 9; the four bolts 21 are in turn After passing through the small round hole 22 of the right end cover 9 and the small round hole 23 of the stator core 5, cooperate with the screw hole 25 of the left end cover 1; after the four cylindrical pins 27 pass through the pin holes 29 of the stator core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com