Fast chopper circuit and method for switched reluctance motor drive system

A technology of switched reluctance motor and drive system, applied in the direction of single motor speed/torque control, control system, control/regulation system, etc. Burnout of the switch tube and other problems, achieve the effect of fast action response, simple and reliable circuit structure, and reduce torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described below with reference to the accompanying drawings.

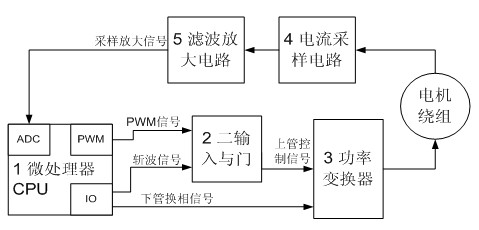

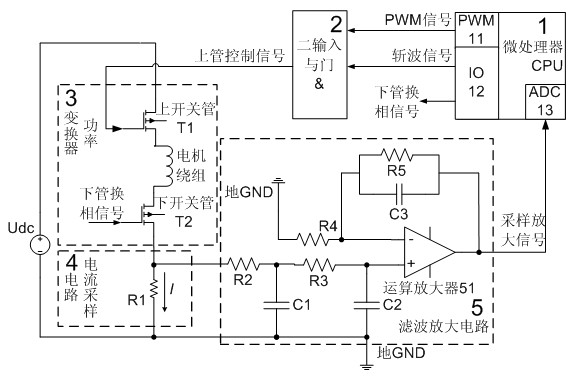

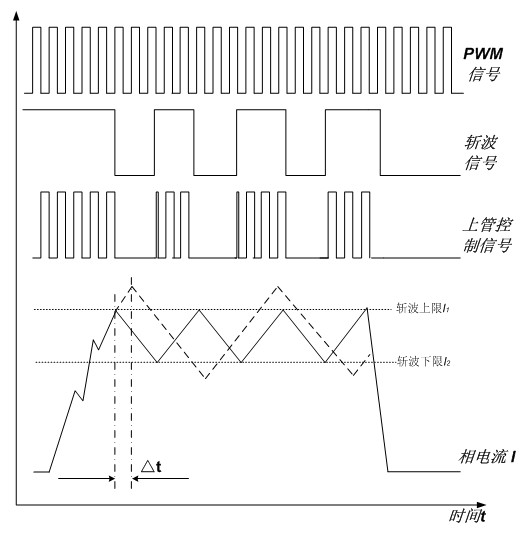

[0030]The invention discloses a fast chopper circuit and method for a switched reluctance motor drive system, which can quickly switch off The control signal of the upper switching tube of the power converter is cut off, so as to achieve a fast chopping effect, and the PWM module of the microprocessor CPU does not need to be turned off. The method and the circuit solve the problem that the switching tube of the power converter may be burnt due to the large delay in the on and off of the output signal of the PWM module of the microprocessor CPU, which leads to the untimely response of the software chopping action. The method and circuit structure are simple, reliable and easy to implement.

[0031] Taking one phase of the power converter and its related control circuit in the three-phase switched reluctance motor as an example, the arrow shows the flow direction of the signal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com