Nut food cooking and drying production line and its working method

A working method and production line technology, which are applied in the field of nut food cooking and drying production lines, can solve the problems that materials are not easy to fully stir, the taste is uneven, and the water phase is not easy, so as to improve the drying effect and utilization rate, the taste is uniform and thorough, and the cooking is improved. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

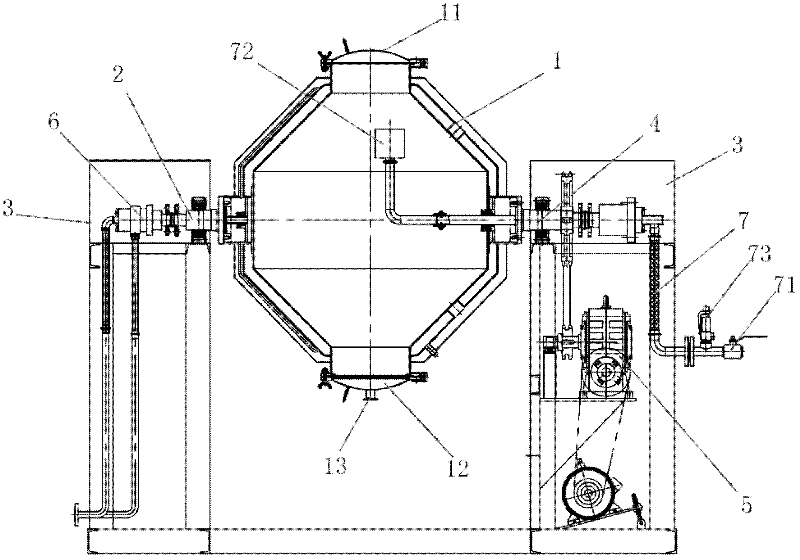

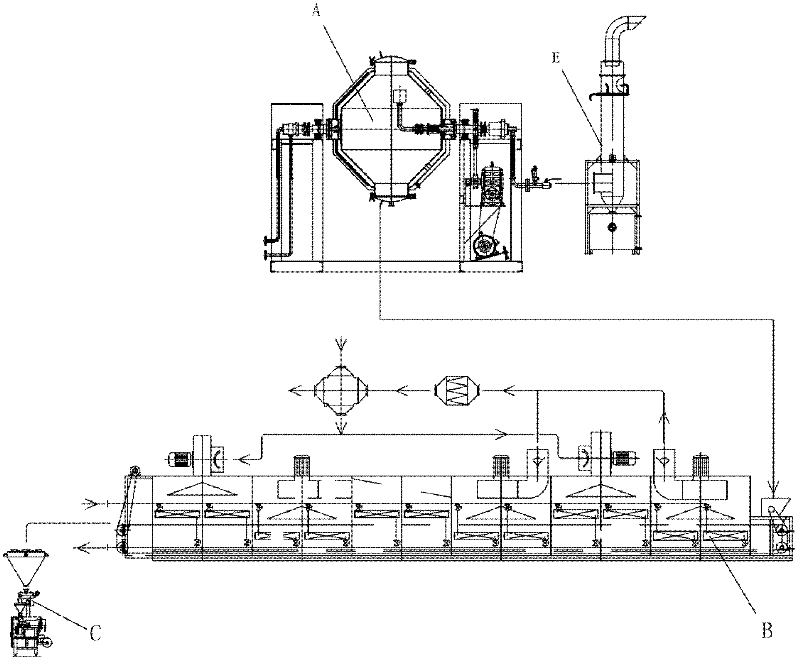

[0025] See Figure 1-4 , the nut food cooking and drying production line of this embodiment, which includes: a rotary cooker A for cooking nut food, a belt dryer B for continuously drying the nut food output from the rotary cooker A, A vacuum packaging machine C that vacuum-packs the nuts output from the belt dryer B, and a water film dust collector E that is connected to the exhaust pipe 7 of the rotary cooker A.

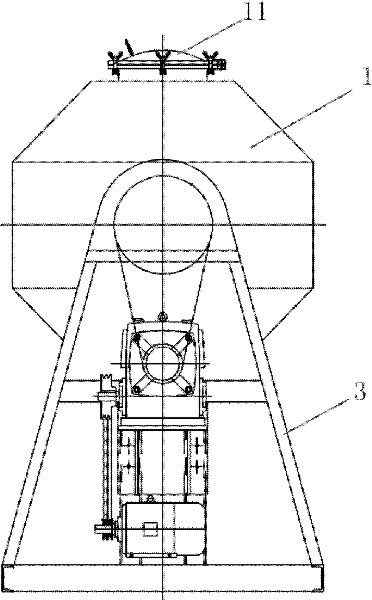

[0026] The rotary cooker A includes: a cooking tank 1 and left and right shafts 2, 4 symmetrically arranged on both sides of the cooking tank 1; on bracket 3.

[0027] The cooking tank 1 is a jacketed tank body suitable for heating by hot steam or heat-conducting oil; the bracket 3 is provided with a pulley drive for driving the right shaft 4 to rotate forward and backward alternately to drive the cooking tank 1 to rotate forward and reverse alternately. Agency 5.

[0028] The left and right shafts 2 and 4 of the rotary cooker are hollow shafts, the left shaft 2...

Embodiment 2

[0034] The working method of the nut food cooking and drying production line in the above embodiment includes:

[0035] Load nuts into the rotary cooker A, the amount of the charge does not exceed 60% of the volume of the rotary cooker A, then add the soup stock and lock the feeding cover 11;

[0036] Rotary cooker A starts to operate, turns on the heat conduction oil pump to heat rotary cooker A; closes the exhaust port valve;

[0037] After cooking for a preset time, stop supplying the heat source, stop the cooking tank 1 and make the discharge port downward; open the control valve 71 to exhaust and release the pressure to normal pressure;

[0038] Open the valve on the liquid discharge port 13 to discharge the liquid. After the feed liquid is exhausted, open the discharge cover 12 to discharge the material and send it into the feeder D at the feed end of the belt dryer B;

[0039] After being dried by the belt dryer B, it is sent to the vacuum packaging machine C for vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com