a bread machine

A technology of bread machines and bread barrels, which is applied in the direction of toasting equipment, baking, household appliances, etc., can solve the problems of polluting the internal environment, low production efficiency, and large space occupation, and achieves increased lubrication area, reduced manufacturing costs, and structural reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

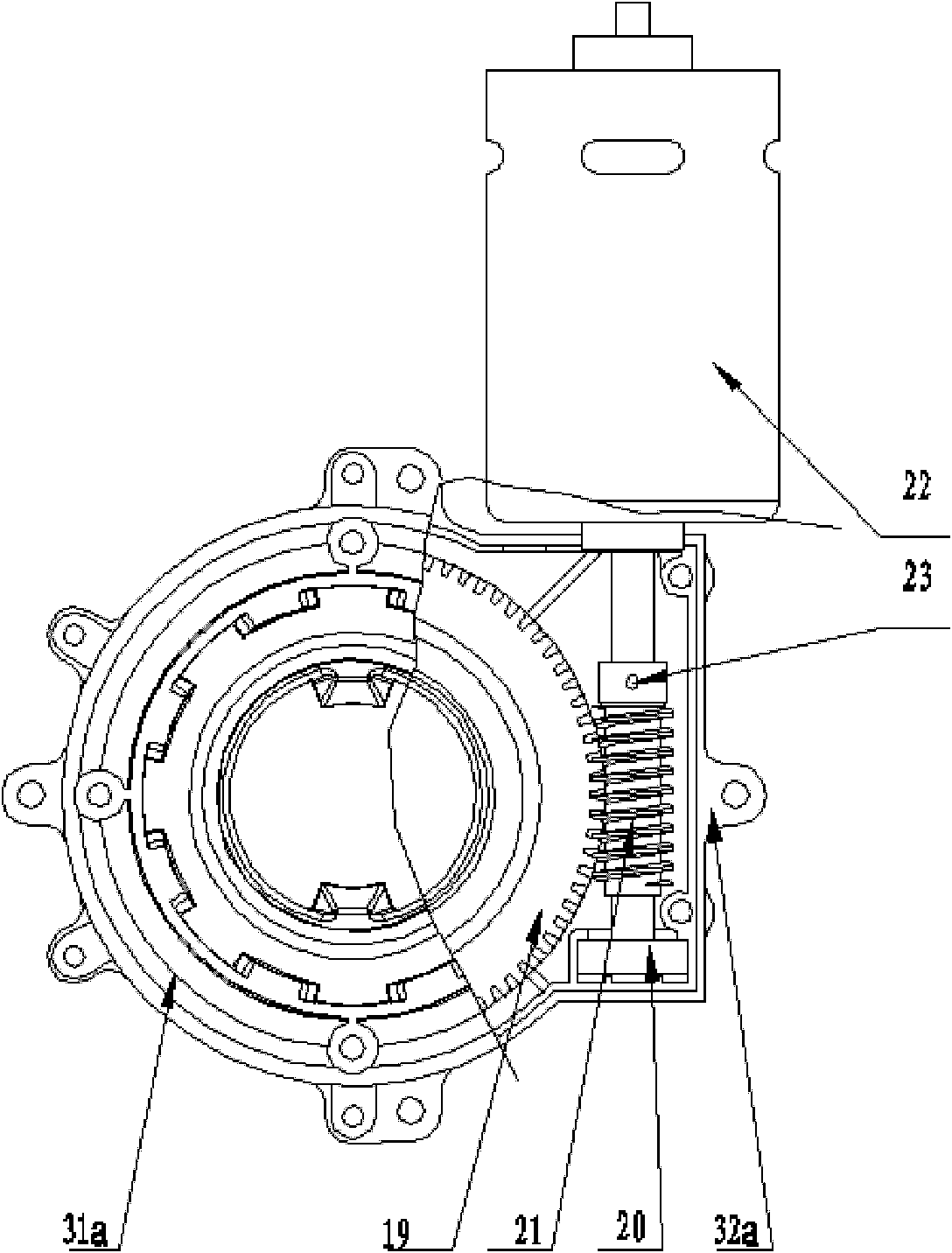

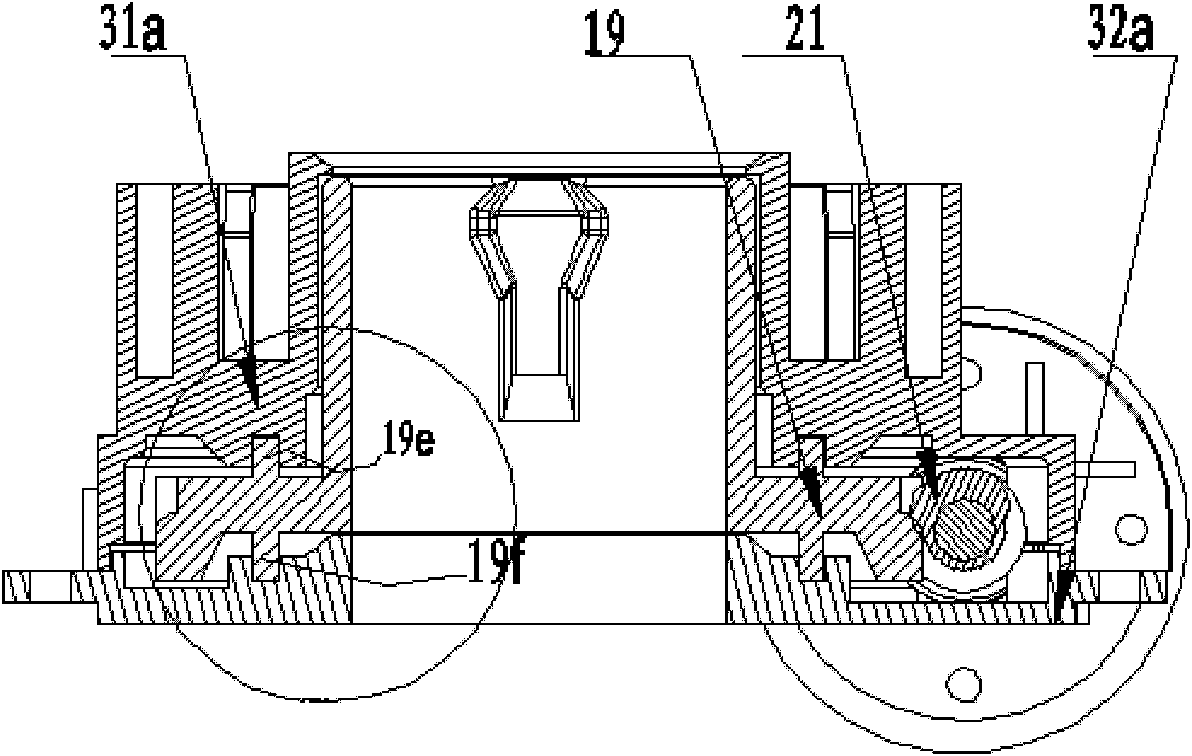

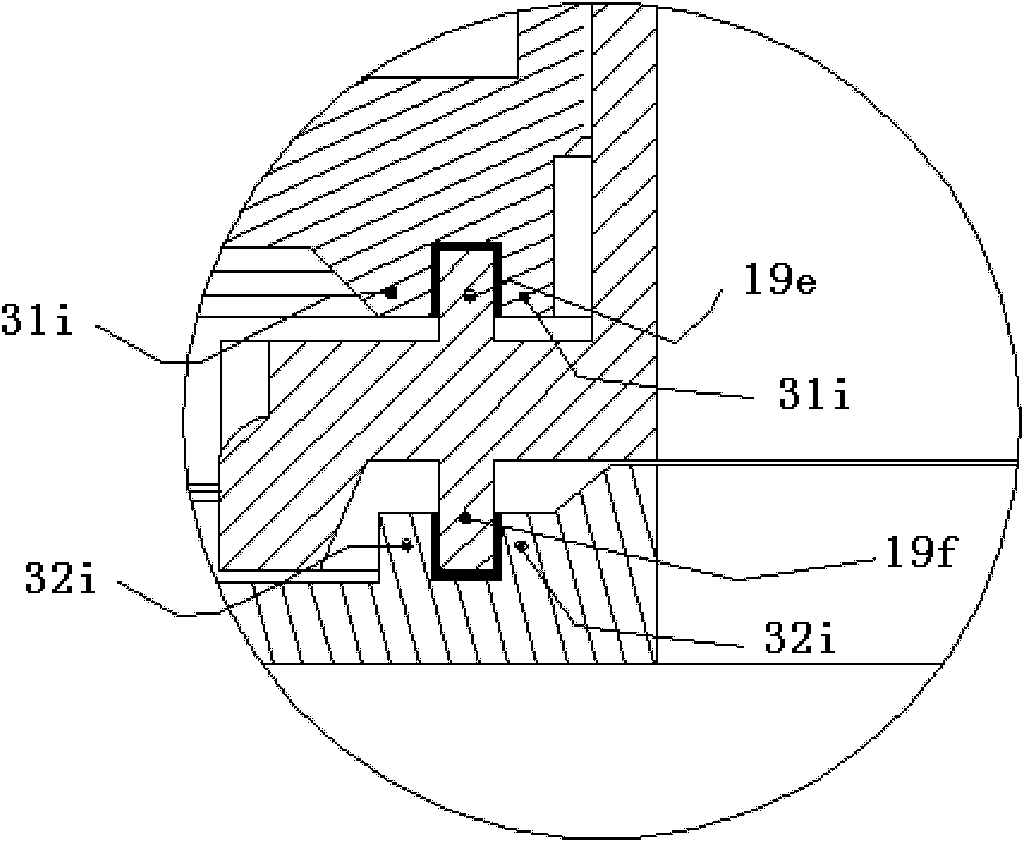

[0043] refer to Figure 1-4 , shows the transmission mechanism of the bread machine, including transmission mechanism upper cover 31a, worm wheel 19, worm 21, rolling bearing 20, transmission mechanism lower cover 32a, motor 22 and rivet 23. The motor (DC or series motor) 22 is connected to the worm 21 through a rivet 23, and the rolling bearing 20 supports the worm 21 to move axially. When working, the motor 22 directly transmits the power to the worm 21, and the worm 21 transmits the power to the worm wheel 19, and the worm wheel 19 decelerates the output power to work, wherein the output shaft of the motor 22 is arranged substantially horizontally. The worm wheel 19 is provided with an upper concentric ring 19e and a lower concentric ring 19f, an upper concentric positioning ring 31i is arranged on the upper cover of the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com