Hepatocyte growth-promoting factor and preparation and application thereof

A hepatocyte auxin and preparation technology, applied in the field of new hepatocyte auxin, can solve the problems of long heating time, cumbersome extraction process, and loss of active substance content, so as to save energy, prevent membrane damage, and avoid degradation The effect of pressing the substance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

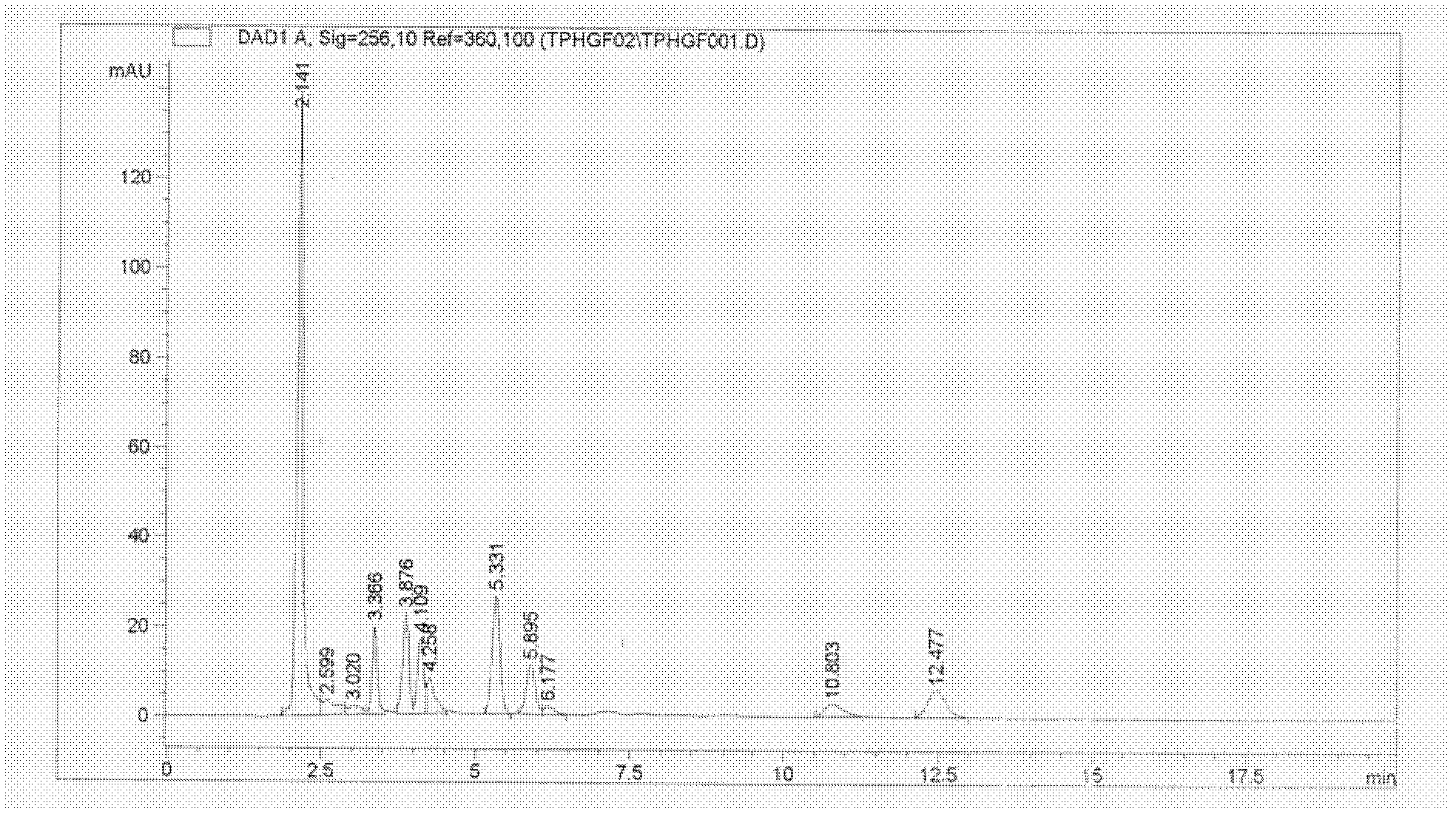

[0062] Example 1 Extraction of hepatocyte growth-stimulating factor

[0063] (1) Material selection: the raw material is fresh suckling pig liver slaughtered on the same day; the weight of a single whole pig liver shall not exceed 140 grams;

[0064] (2) Tissue processing: After the fascia and pedicles of suckling pig liver are removed, wash with pure water; cut into 2-3 pieces with a stainless steel knife to facilitate homogenization;

[0065] (3) Mix with water for injection at room temperature, the speed of homogenate is 800~1000 rpm, the time is: 5min, the ratio is water: pig liver mass ratio is 11:1; Freeze to 0°C, then freeze to -35°C at a rate of 4°C / min;

[0066] (4) After thawing the homogenate that has been frozen at -10~-25℃ for at least 7 days, heat it to 83℃~85℃, remove the heating source immediately, put it into a filter cloth and filter it naturally, and adjust the pH value of the filtrate with NaOH solution to 6.5, the speed of thawing and heating is 1~2℃ / min...

Embodiment 2

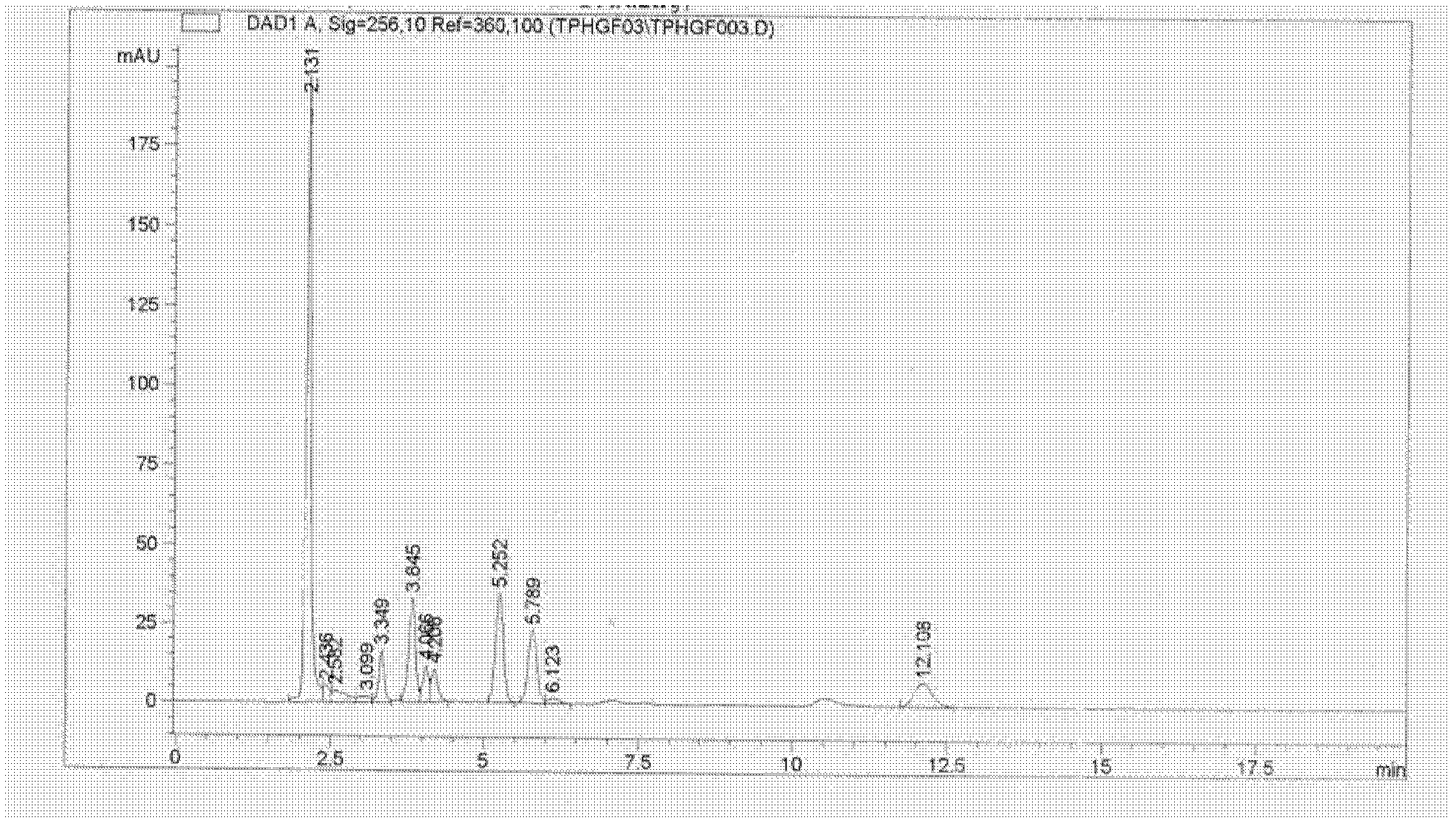

[0075] (1) Material selection: the raw material is fresh suckling pig liver slaughtered on the same day; the weight of a single whole pig liver shall not exceed 140 grams;

[0076] (2) Tissue processing: After the fascia and pedicles of suckling pig liver are removed, wash with pure water; cut into 2-3 pieces with a stainless steel knife to facilitate homogenization;

[0077] (3) mix with water for injection at room temperature, the speed of homogenate is 800~1000 rpm, the time is 5 minutes, the ratio is water: pig liver mass ratio is 115: 1; Freeze at room temperature to -5°C, and then freeze to -35°C at a rate of 5°C / min.

[0078] (4) After thawing the homogenate that has been frozen at -35°C for at least 7 days, heat it to 83°C-85°C and immediately remove the heating source, put it into a filter cloth and filter naturally, and adjust the pH value of the filtrate to 6.5 with NaOH solution; thaw And the heating speed is raised to 0°C at a rate of 2°C / min, and then heated to ...

Embodiment 3

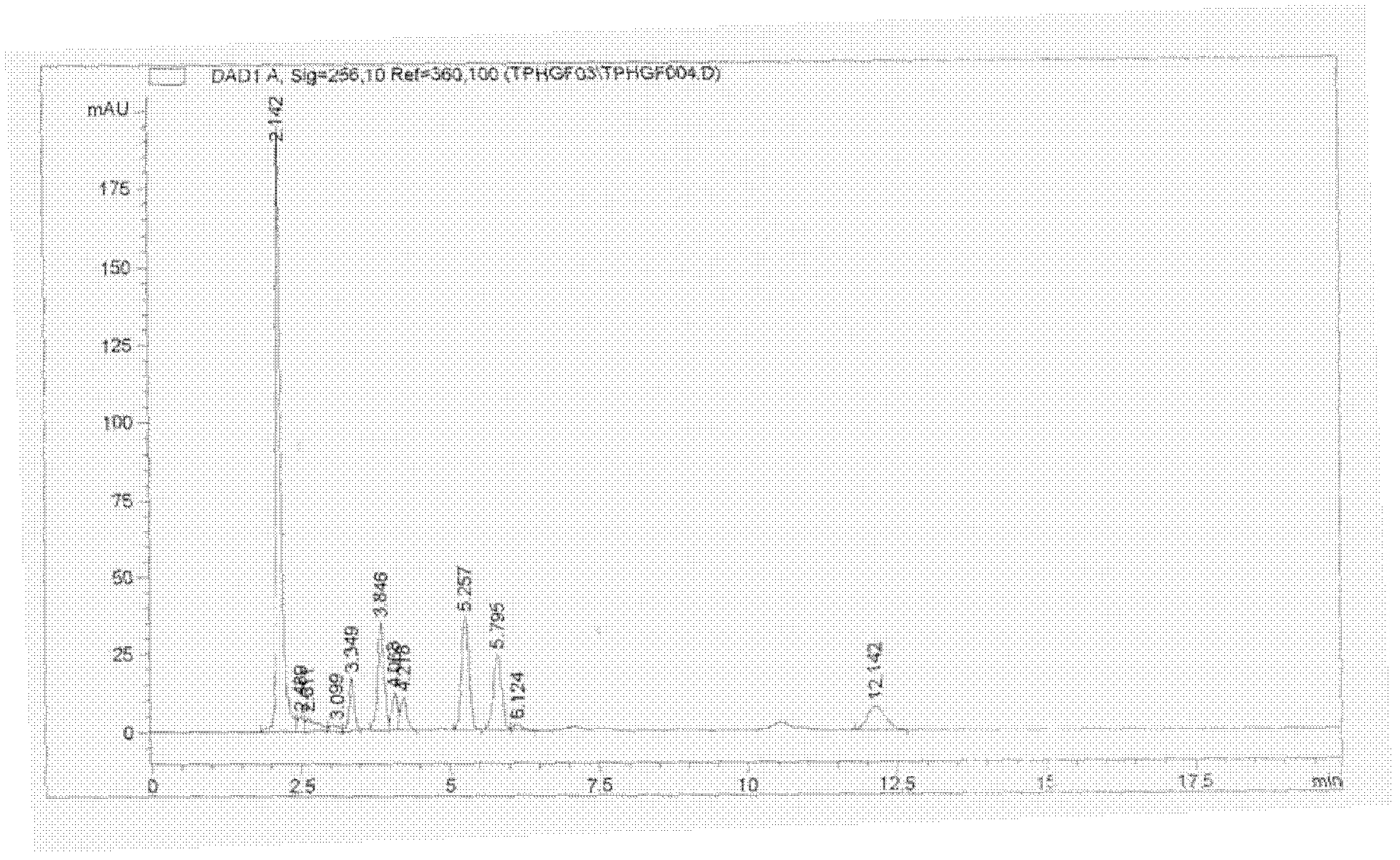

[0087] (1) Material selection: the raw material is fresh suckling pig liver slaughtered on the same day; the weight of a single whole pig liver shall not exceed 140 grams;

[0088] (2) Tissue processing: After the fascia and pedicles of suckling pig liver are removed, wash with pure water; cut into 2-3 pieces with a stainless steel knife to facilitate homogenization;

[0089] (3) Mix with water for injection at room temperature, the speed of homogenate is 800-1000 rpm, the time is 5 minutes, the mass ratio of water and pig liver is 11:1; the homogenate is frozen from room temperature at a speed of 18°C / min to -2°C, and then frozen to -28°C at a rate of 8°C / min;

[0090] (4) After thawing the homogenate that had been frozen at -30°C for at least 7 days, heat it to 83°C and immediately remove the heating source, put it into a filter cloth and filter it naturally, and adjust the pH value of the filtrate to 6.5 with NaOH solution;

[0091] (5) The solution adjusted to pH 6.5 is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com