Activated carbon composite material and application thereof in lead-carbon battery

A composite material, lead-carbon battery technology, used in lead-acid batteries, lead-acid battery electrodes, battery electrodes, etc., can solve problems such as hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

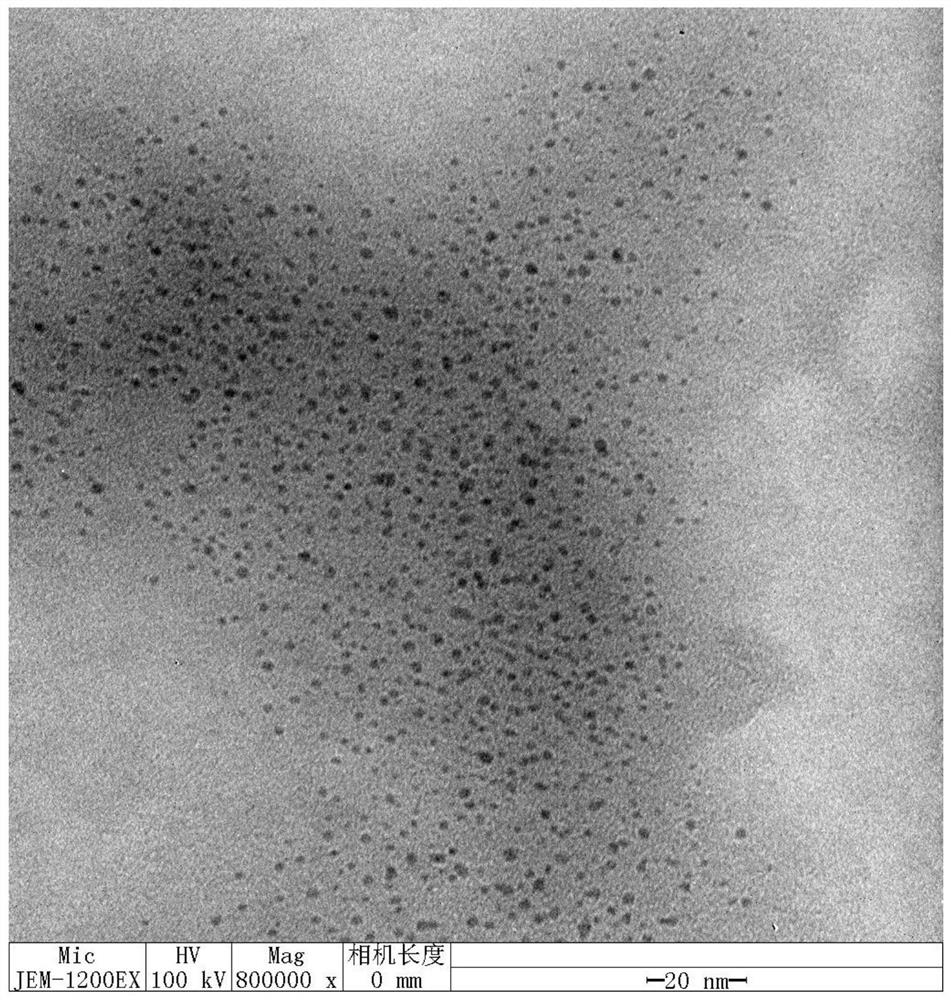

[0034] Step 1, adopt the following method to prepare monodisperse atomic cluster-activated carbon composite material:

[0035] 1) Prepare liquid A:

[0036] 300mg of indium nitrate and 5ml of 40wt% polysodium methacrylate (PMAA-Na) solution were dissolved in 100ml of water;

[0037] 2) Prepare B slurry:

[0038] Add liquid A dropwise to 10g of activated carbon material while stirring to form B slurry state; the specific surface area of activated carbon is 1800m 2 / g; the surface area of the activated carbon used is about 18000m after testing and calculation 2 ;

[0039] 3) Put the B slurry in an ice-water bath at 0°C while stirring, add 0.5g of sodium borohydride (NaBH 4 ) was dissolved in 100ml of water and added dropwise to the B slurry, the dropping time was controlled to be 10min, and the stirring was continued for 2h after the dropping;

[0040] 4) Drying at 80°C for 12 hours to obtain a monodisperse atomic cluster-activated carbon composite material.

[0041] T...

Embodiment 2

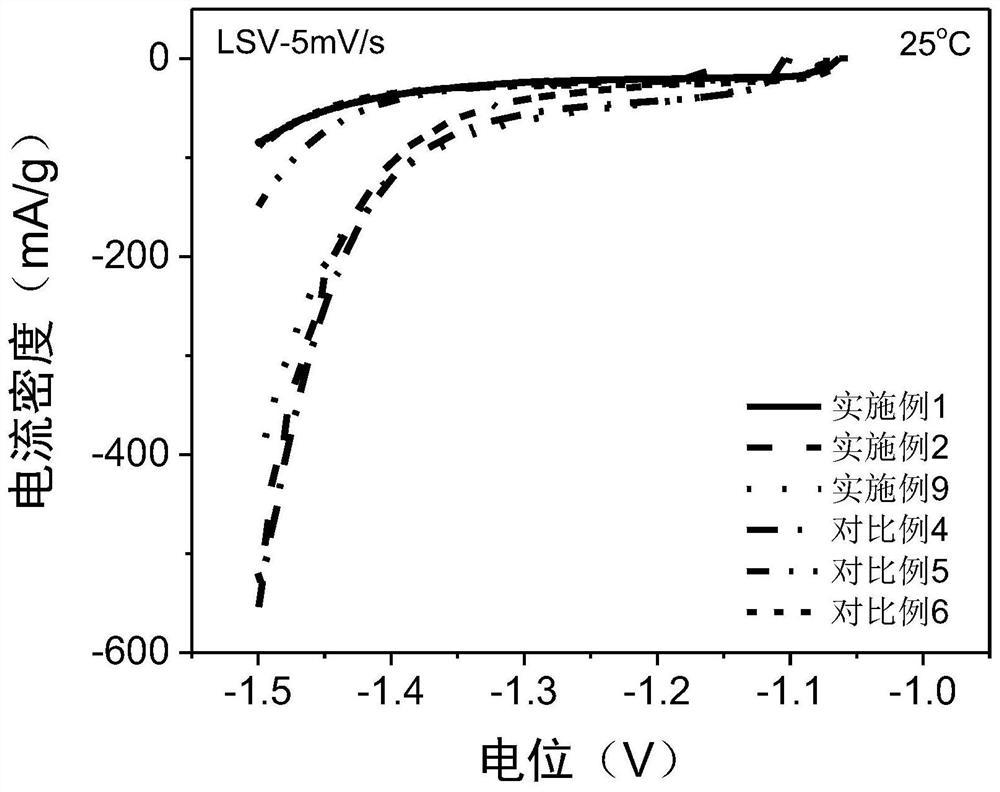

[0044] Lead-carbon battery: according to the requirements of Example 1, without changing other conditions, polysodium methacrylate (PMAA-Na) was replaced by polyethylene glycol dimethacrylate with the same volume and concentration. Get 0.21g of the prepared lead-carbon battery negative active material as the working electrode, 0.36g of the positive active material as the counter electrode, take the commercial mercury-mercurous sulfate reference electrode and carry out the three-electrode system LSV test, the test range is (-1)V to (-1.6)V, the test results are as follows figure 2 . The morphology of the prepared monodisperse atomic cluster-activated carbon composite shows that the size of the atomic cluster is about 1nm.

Embodiment 3

[0046] According to the requirements of Example 1, without changing other conditions, the addition amount of indium nitrate was changed to 600mg. The internal hybrid battery can run 14400 laps under this condition. Compared with the test results of ordinary lead-acid batteries with the same lead element content under the same test conditions (7200 cycles), the life of the internal mixed lead-carbon battery can reach twice the life of the traditional lead-acid battery. The morphology of the prepared monodisperse atomic cluster-activated carbon composite shows that the size of the atomic cluster is about 3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com