A method for increasing the strength of carbon fiber

A carbon fiber and strength technology, used in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of high cost and unsatisfactory "repair" efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0019] 1. Preparation of spraying liquid:

[0020] Take the commercially available carbon nanotubes and the dispersion liquid prepared by ionic liquid and water and mix them in a container according to the required ratio, and then use ultrasonic waves with a frequency of 25kHz to perform ultrasonic vibration for about 4 hours, so that the carbon nanotubes are dispersed Fully dispersed in the liquid, then prepared into the required concentration of spray liquid for use.

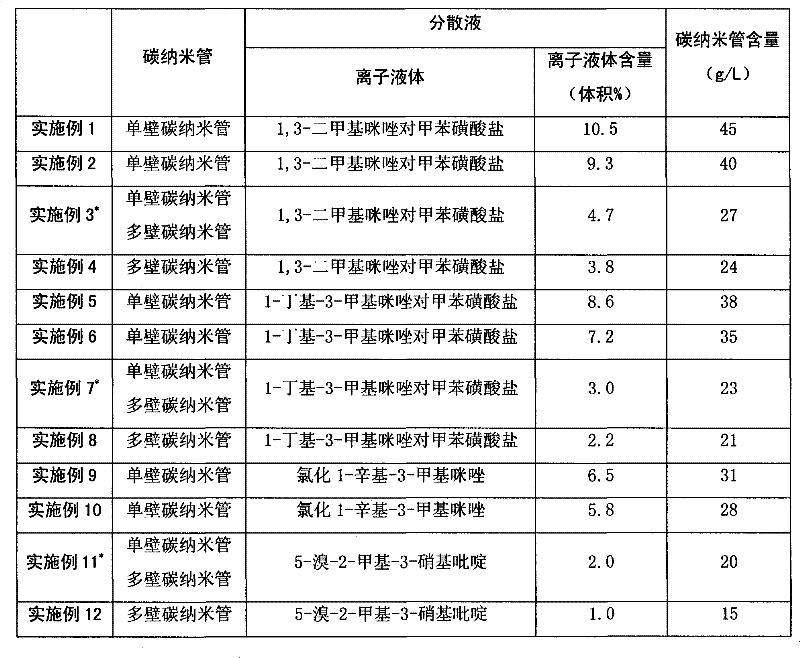

[0021] The composition of the spraying liquid in each embodiment is shown in Table 1. The diameter distribution of the single-wall carbon nanotubes used is 0.5-5 nm, the diameter distribution of the multi-wall carbon nanotubes is 10-20 nm, and the length distribution is 10-30 μm.

[0022] Table 1.

[0023]

[0024] *The weight ratio of single-walled carbon nanotubes to multi-walled carbon nanotubes is 1:1.

[0025] 2. Electrostatic spraying of carbon nanotubes on the surface of carbon fiber

[0026] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com