Quick Repair Method of Existing Expansion Joints in Railway Concrete Bridges

A repair method and concrete technology, applied in bridge maintenance, bridges, bridge parts, etc., can solve the problems of loss of waterproof and sealing function, poor embedding of rubber strips, failure to achieve waterproofing of bridge decks, etc. Maintenance and repair, easy to use in large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

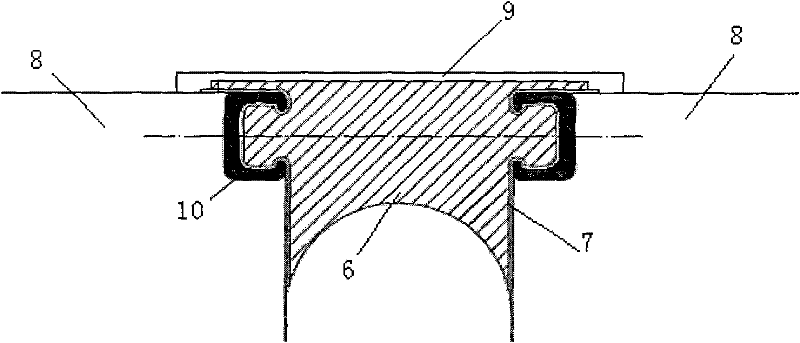

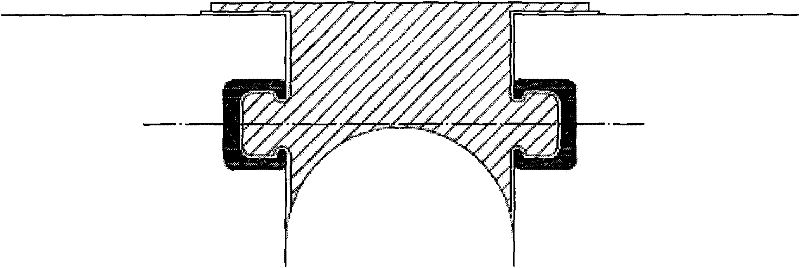

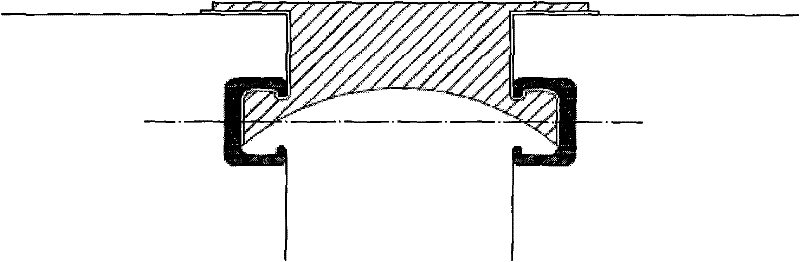

[0031] will now refer to Figure 1-5 A preferred embodiment of the present invention will be described in detail. in, figure 1 It is a structural schematic diagram of a railway bridge expansion joint repaired according to a preferred embodiment of the present invention.

[0032] A rapid repair method for existing expansion joints of railway concrete bridges, comprising the following steps: a. removing residual water-stop rubber strips; b. removing scum, floating soil, oil stains, Rust and other dirt and rubbish, then dry; c, according to the condition of the beam end and the width of the beam gap, select the bottom lining and side lining, install and position the bottom lining and side lining, and the bottom lining is composed of multiple sections of 2-3m Splicing of long plate-shaped or rod-shaped materials; d. Spraying the primer: the primer should be sprayed evenly, without accumulation and not exposed to the bottom surface; e. Pouring repair materials: after the primer ...

Embodiment 2

[0036] Next, refer to figure 1 Another preferred embodiment of the present invention will be described in detail. A quick repair method for existing expansion joints of railway concrete bridges, comprising the following steps:

[0037] a. Clearance of the failed existing expansion joints: The failure of the existing expansion joints of high-speed railway bridges mainly manifests in the shedding and peeling of the water-stop rubber strips, the blockage of the drainage channels, and cannot be repaired and replaced. Therefore, the quick repair must first remove the original water-stop rubber strip; for the ballasted track, the ballast retaining cover plate must also be removed.

[0038] b. Cleaning and drying the bonding base surface: the treatment of the base surface is the process of removing scum, floating soil, oil stains, rust and other dirt and garbage on the exposed surface of the concrete base surface and metal edge beams, and drying them , special attention should be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com