Roof steel structure for cement production line clinker warehouse and construction method thereof

A steel structure construction and production line technology, which is applied in large-capacity bulk material storage, building types, buildings, etc., can solve the problems of less aerial work, high precision requirements for assembling tires, and long assembly time, and achieves steel structure design. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

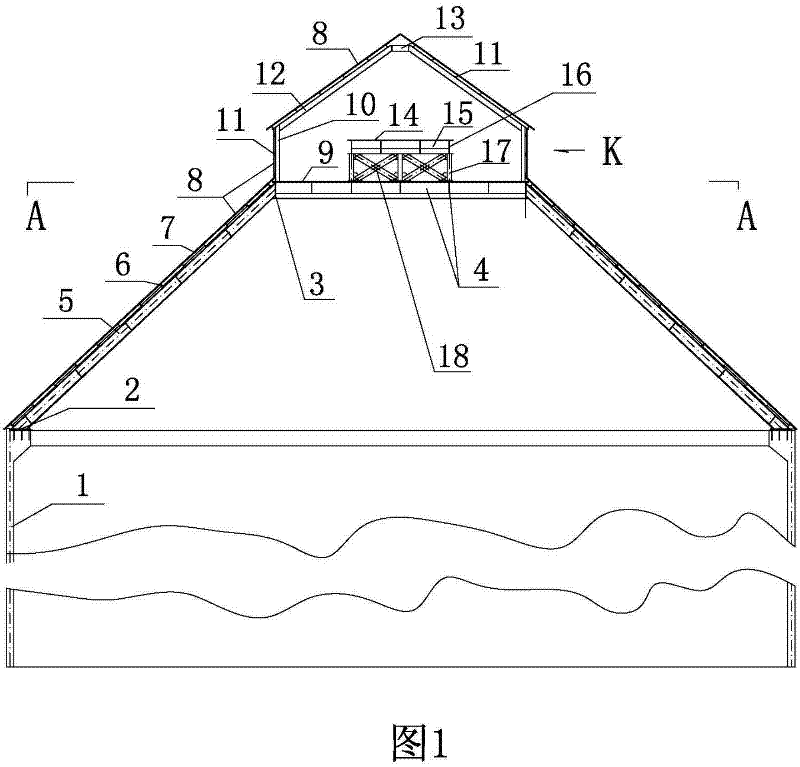

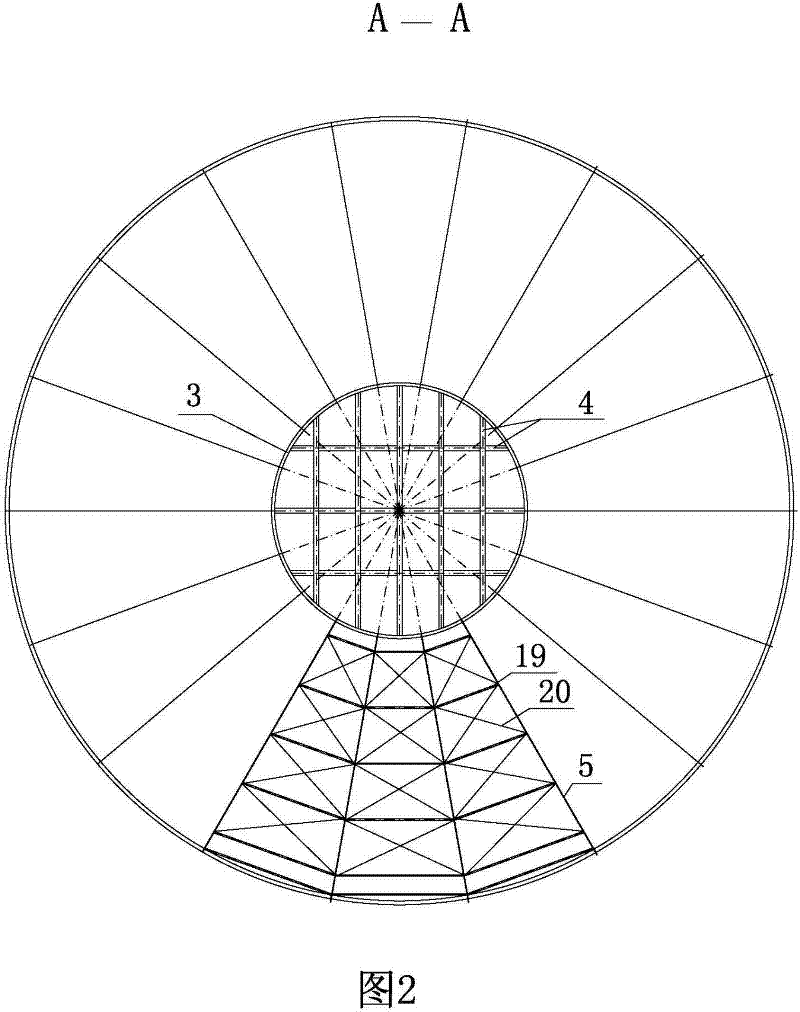

[0045] The clinker storage warehouse of the cement production line is a cast-in-place reinforced concrete circular silo 1 with a diameter of 40m, mainly including a 25.25m roof steel structure, a 37.10m ring beam steel platform, a 40.710m steel platform and a warehouse roof.

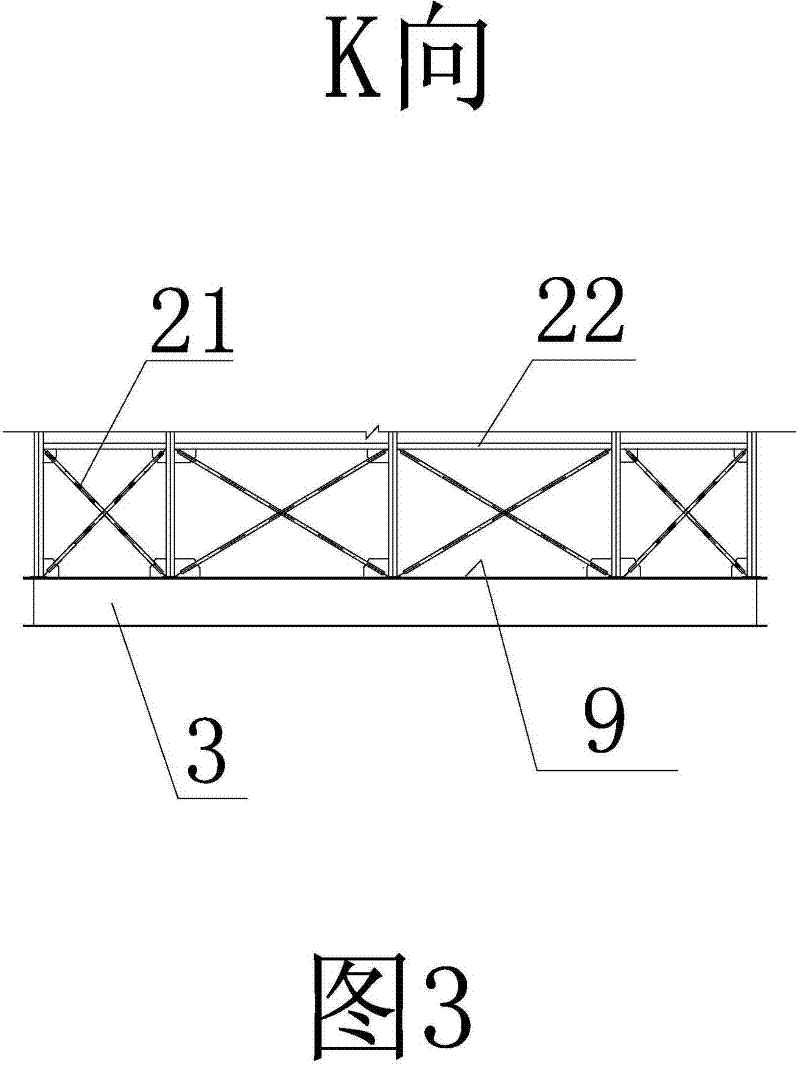

[0046] The lower cone of the 25.25m roof steel structure has an elevation of 25.300m and a diameter of 40.00m; the elevation of the upper cone is 37.10m and a diameter of 12.800m. The steel structure roof is composed of 18 H650×300×14×16 oblique beams 5, oblique supports 20 and horizontal supports 19 made of round steel pipes, the roof is made of Z-shaped steel purlins 6, and the braces 7 are made of round steel. The lower opening of the inclined beam 5 is bolted and welded to the pre-embedded connector 2 on the top of the wall of the concrete circular silo 1, and the upper opening is welded to the single-sided groove of the H850×400×16×28 ring beam 3 with an elevation of 37.10m.

[0047] The ring beam 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com