A vertical multi-storey wind power generation system that is combined and stabilized by the foundation platform and the frame steel cable

A technology of wind power generation system and foundation frame, which is applied to wind power generator components, wind power generation, wind power generators, etc. It can solve the problems of small anti-overturning torque and weak anti-storm damage ability, so as to increase the installed capacity and increase the resistance to wind. The effect of overturning moment, anti-storm destruction ability, and improvement of wind field land utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

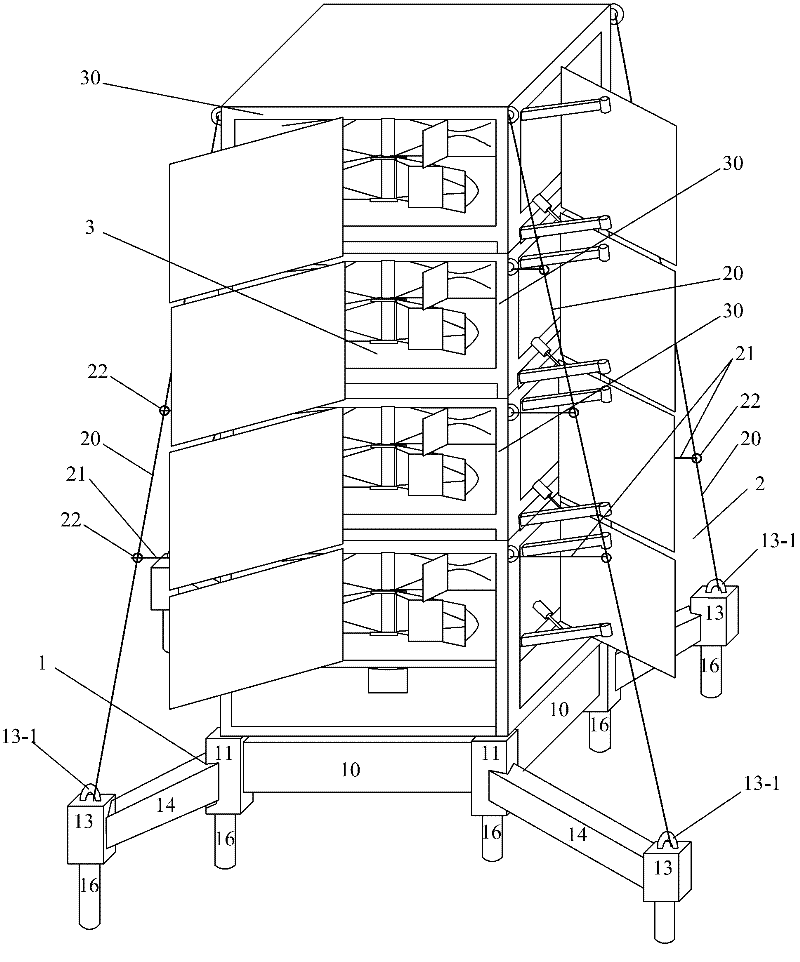

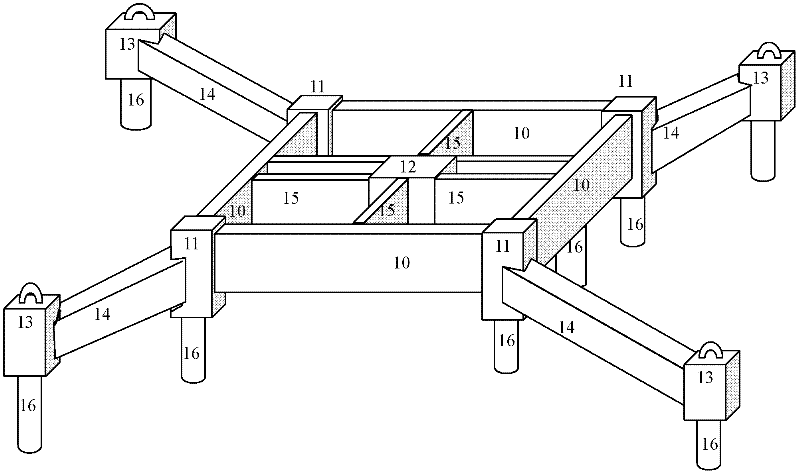

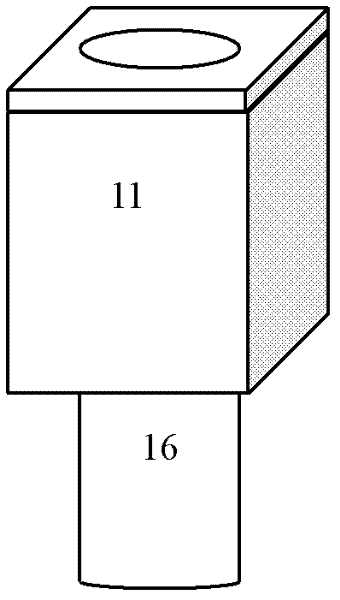

[0024] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, the vertical multi-layer wind power generation system that the foundation platform and the frame steel cable of the present embodiment are combined and stabilized, it includes the multilayer composite wind power system 3 and the frame steel cable stabilization system 2; The stable vertical multi-storey wind power generation system also includes a foundation platform 1, and the foundation platform 1 includes a plurality of foundation beam reinforcement skeletons 10, a plurality of column and square pier reinforcement reinforcement skeletons 11, a generator base reinforcement reinforcement skeleton 12, and a plurality of fixed steel skeletons. Cable square pier reinforcement skeleton 13, multiple fixed steel cable square pier support beam reinforcement skeletons 14, multiple internal support beam reinforcement skeletons 15, multiple ground pile reinforcement skeletons 16, and multiple...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination Image 6 Describe this embodiment, the frame steel cable stabilization system 2 of this embodiment includes a plurality of cable-stayed main cables 20 and a plurality of transversely-stayed horizontal steel cables 21, the top angle of the box frame 30 at the top of the multilayer composite wind power system 3 Each is tensioned and connected with the pull ring 13-1 on the corresponding fixed steel cable square pier steel frame 13 through a cable-stayed main steel cable 20, and the rest of the multi-layer composite wind power system 3 except the top box frame 30 The top corners of the box frame 30 are respectively connected to the corresponding cable-stayed main steel cables 20 through a transversely-stayed horizontal steel cable 21 . With this setting, the vertical multi-layer wind power generation system and the foundation platform 1 can maintain a good verticality, so that the deformation of the overall box frame is small, ...

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Image 6 The present embodiment is described, and the transversely-stayed horizontal steel cables 21 of the present embodiment are connected to the corresponding main cable-stayed cables 20 through the connection ring 22 . In this way, the horizontal steel cable 21 can automatically slide on the cable-stayed main steel cable 20 through the connecting ring 22, so that the box frame 30 of each layer can be automatically adjusted and balanced by the tension of the steel cable, so that the vertical multi-layer wind power generation system and the foundation The maximum verticality is maintained between platforms 1 to minimize the deformation of the overall box frame. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com