Pasting machine transmission clutch method and device for implementing the method

A technology for pasting machines and drive shafts, applied in transmission devices, gear transmission devices, mechanical drive clutches, etc., can solve problems such as difficulty in ensuring product quality, poor running stability, and prolonging the production cycle, so as to achieve convenient maintenance and debugging. The effect of stable operation and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

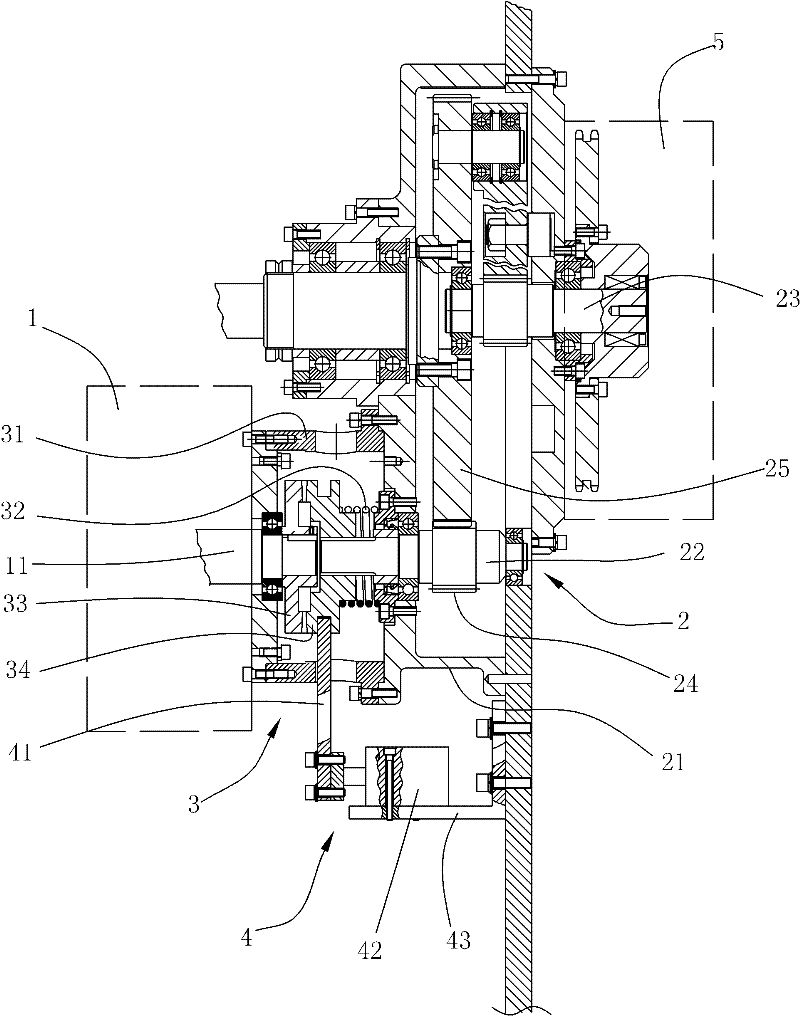

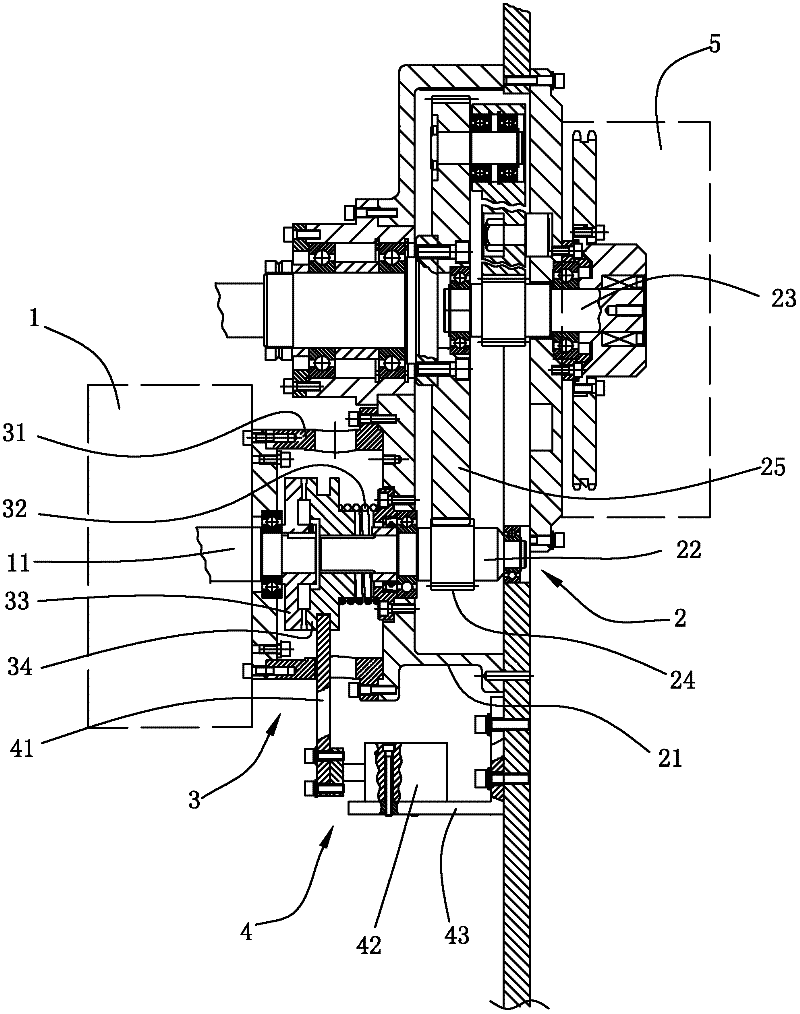

[0048] Example: see figure 1 and figure 2 , the embodiment of the present invention provides a method for transmission and clutching of a paste machine, which includes the following steps:

[0049] (1) Drive shaft 11 is set, for the power output of paster 1; Described step (1) specifically comprises the following steps: described drive shaft 11 is horizontally arranged on transmission gear case 2 side, and makes it It is arranged concentrically with the transmission shaft 22 .

[0050](2) transmission gear box 2 is set, realizes that paste machine 1 is connected with its supporting functional equipment, and drive shaft 11 can synchronously drive described functional equipment to work through this transmission gear box 2; (2.1) a casing 21 is set (2.2) a transmission shaft 22 is set, which is used to be connected with the drive shaft 11; (2.3) an output shaft 23 is set, which is used to output the power of the drive shaft 11; (2.4) a gear A24 and a gear with the gear are set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com