Full-automatic on-line monitoring system of COD (chemical oxygen demand) and monitoring method thereof

A monitoring system, fully automatic technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of automatic dilution, cleaning, automatic online detection, low sensitivity, etc., and achieve the effect of consistent volume, good conductivity, and low background current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

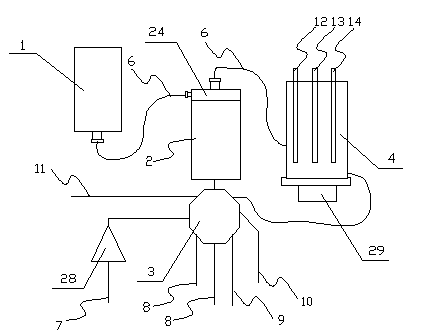

[0025] Embodiment 1: the COD automatic online monitoring system of the present embodiment, as figure 1 As shown, it includes electric injector 1, optical quantitative device 2, multi-way adapter 3, reaction tank 4 and monitoring control device 5, between electric injector 1 and optical quantitative device 2, between optical quantitative device 2 and reaction tank 4 All are connected with ventilation pipe 6. There are many pipelines inside the multi-way adapter 3, and there are a plurality of electromagnetic valves 27 on the multi-way adapter 3, and each electromagnetic valve controls the on-off between the internal pipelines. The solution input pipe 7 to be tested is connected to the multi-way adapter 3 through the pretreatment system 28, and the multi-way adapter 3 is also connected with two standard solution input pipes 8, blank solution input pipe 9, and deionized water input pipe 10. And the waste liquid discharge pipe 11, the multi-way adapter 3 is also communicated with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com