Setting method of moisture control parameters for sintering granulation to effectively suppress raw material flow fluctuation

A technology of flow fluctuation and control parameters, applied in the direction of flow control, non-electric variable control, adaptive control, etc., can solve problems such as flow fluctuation of mixture adding water, water disturbance of mixture, and inability to stabilize moisture well, to ensure The effect of stable operation, reduction of moisture fluctuation, and suppression of uneven mixing and granulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

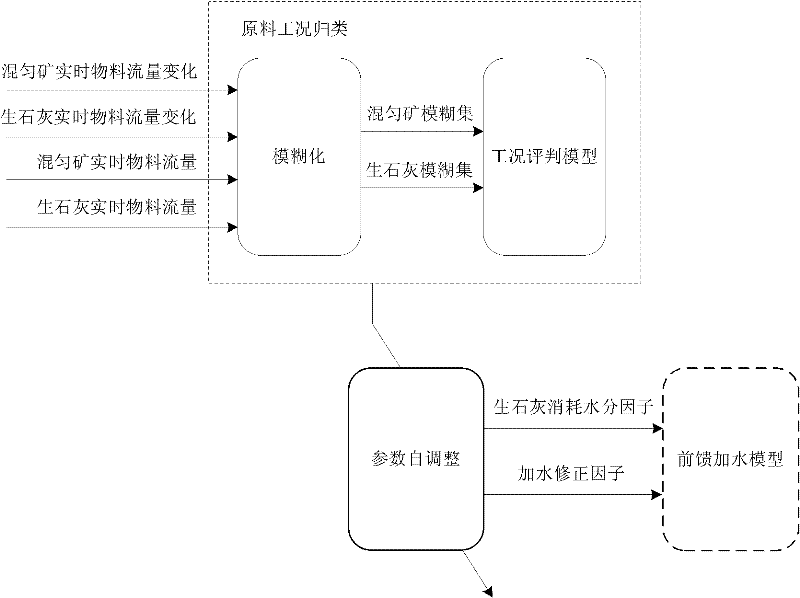

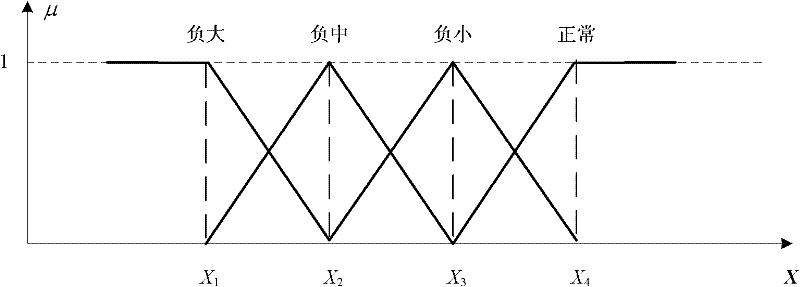

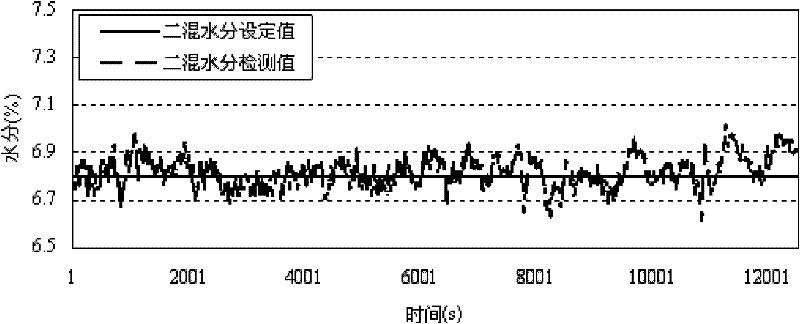

[0052] like figure 1 As shown, the feed-forward water addition control structure of the present invention mainly consists of raw material working condition classification, parameter self-adjustment and feed-forward water addition model, actual detection of real-time raw material flow and its change rate of mixed ore, quicklime real-time raw material flow and its change rate, etc. After the value is fuzzified, the fuzzy comment set of the mixed ore and quicklime is obtained, and then the working conditions of the two are obtained through the raw material working condition evaluation model, the expert rules are queried, and the quicklime consumption factor and the water correction factor are adjusted online. These two parameters are directly applied Based on the calculation of the feed-forward water addition model, the water addition flow rate of the mixing cylinder is finally obtained.

[0053] The real-time raw material flow rate is the instantaneous total amount of raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com