Arrangement and method for measurement of temperature and of thickness growth of silicon rods in silicon deposition reactor

A reactor and silicon deposition technology, applied in chemical instruments and methods, measuring devices, semiconductor/solid-state device testing/measurement, etc., can solve short-term problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

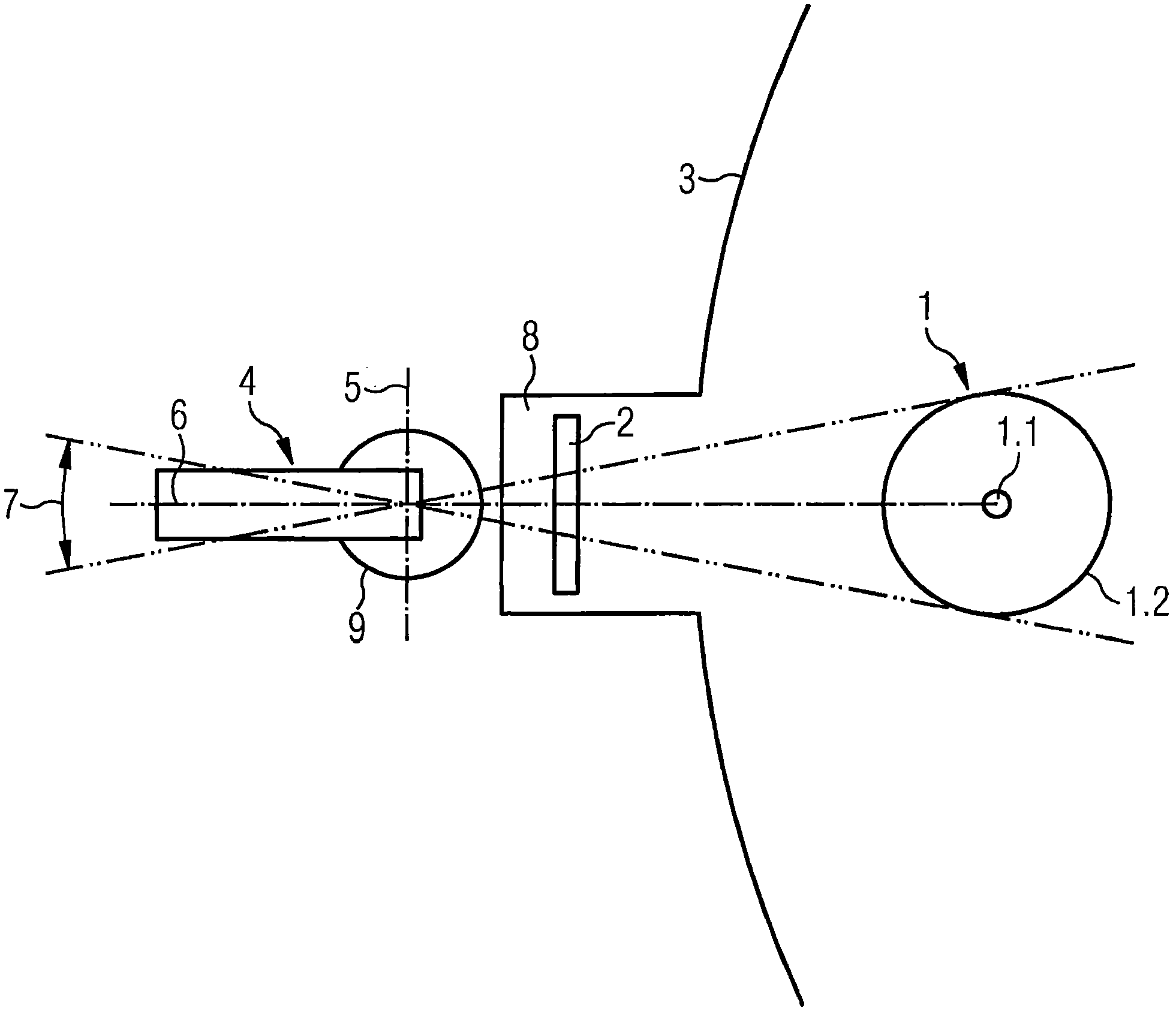

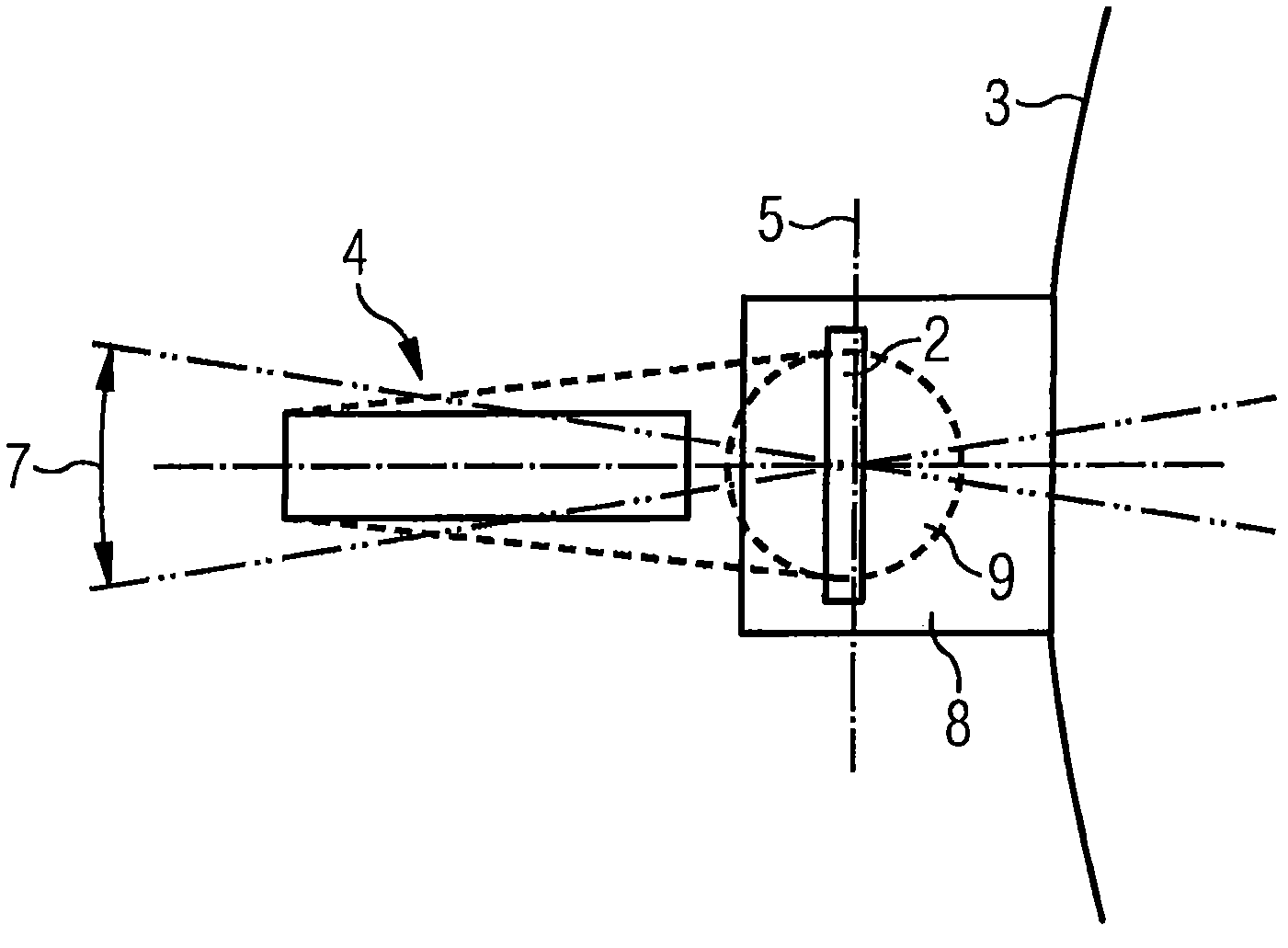

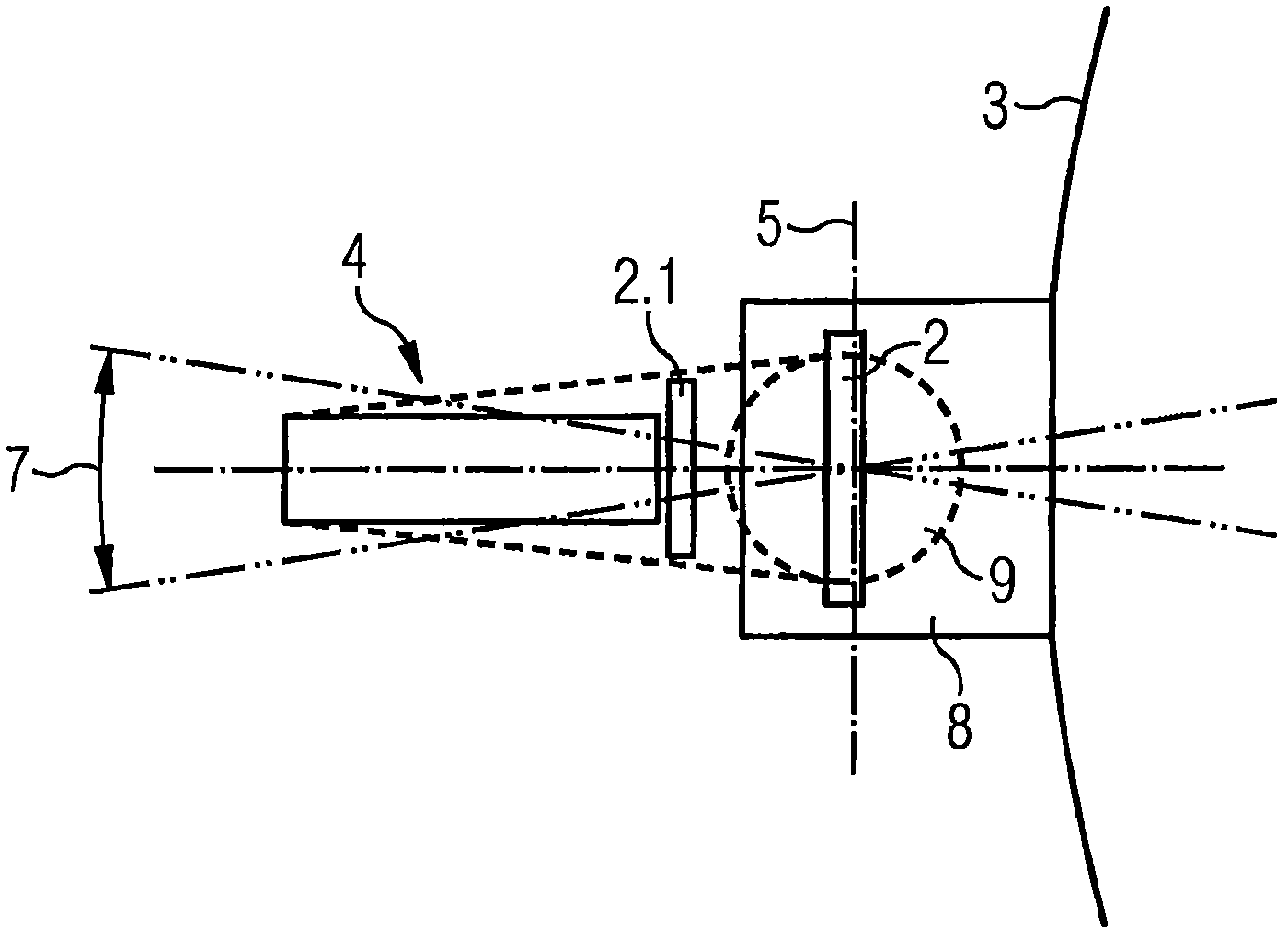

[0035] according to figure 1 , the device for temperature measurement of silicon rods 1 in a silicon deposition reactor through a viewing window 2 in the reactor wall 3 comprises a contactless operating temperature measuring device 4 which can pivot about a pivot axis 5 . The pivot axis 5 extends parallel to the longitudinal axis 6 of the silicon rod 1 . Furthermore, the longitudinal axis 6 of the temperature measuring device 4 extends through the pivot axis 5 .

[0036] figure 1 The silicon rod 1 is shown in two states, specifically the thin silicon rod 1.1 and the silicon rod 1.2 after the end of the process.

[0037] exist figure 1 In the variant shown, the pivot axis 5 is located on the outside of the reactor wall 3 of the silicon deposition reactor in front of the viewing window 2 housed in a tubular connecting stud 8 protruding outside the tube wall 3 .

[0038] A motor adjustment device in the form of a rotary drive 9 is provided for the pivotal drive of the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com