Thinning lightweight packaging material and preparation method thereof

A packaging material and lightweight technology, which is applied in the field of thinning and lightweight packaging materials and its preparation, can solve the problems of wasting social resources and high energy consumption, and achieve the effects of high safety performance, high sealing strength and moderate barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

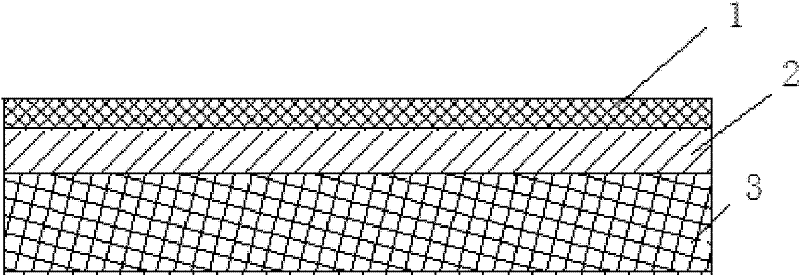

Method used

Image

Examples

Embodiment 1

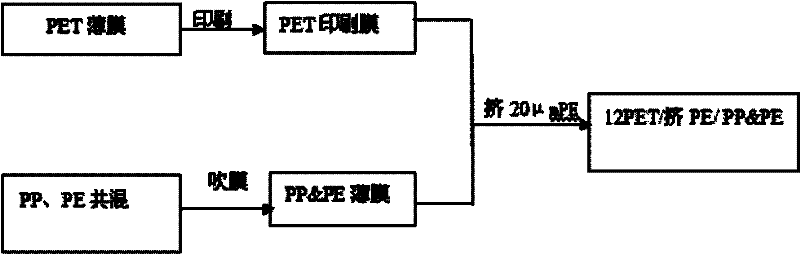

[0054] 1) Printing process: that is, between 20-30 ° C, the PET thin material is printed in color by a printing machine,

[0055] 2) Polypropylene and polyethylene blending and co-extrusion thin material layer preparation process: The materials of the corona layer, the middle layer and the heat-sealing layer are respectively loaded into the three-layer co-extrusion thin material blow molding unit (M3B-1300Q ) in the three hoppers for blowing materials;

[0056] Corona layer: 75KgRC1314 (co-PP); 20KgSP1520; 5Kg150BW; 0.5Kg100991-k

[0057] Middle layer: 25KgF920A; 25Kg1018FA; 25Kg2426H; 18Kg white female F501; 0.2Kg100991-k;

[0058] Heat seal layer: 25Kg Yanshan 100AC; 25Kg1002KW; 25Kg5100G; 1.8KgSE07PE; 1KgAB-20LD; 0.2Kg100991-k

[0059] Outer layer: RC1314 (co-PP) is a copolymerized PP, which has good compatibility with PE in terms of melting point and melting index. SP1520 is 6C MLLDPE, because metallocene polyethylene and PP materials have good blending compatibility, t...

Embodiment 2

[0070] Except 2) preparation process of polypropylene and polyethylene blending and co-extrusion thin material layer: middle,

[0071] Corona layer: 65KgRC1314 (co-PP); 25KgSP1520; 7Kg150BW; 0.5Kg100991-k

[0072] Middle layer: 25KgF920A; 30Kg1018FA; 30Kg2426H; 15Kg white female F501; 0.3Kg100991-k;

[0073] Heat seal layer: 25Kg Yanshan 100AC; 30g1002KW; 30Kg5100G; 1.5KgSE07PE; 0.8KgAB-20LD; 0.3Kg100991-k;

[0074] 3) In the extrusion compounding process,

[0075] The weight ratio of LDPE 1C7A to SP1071C is 1:3

[0076] Outside, all the other are identical with embodiment 1.

Embodiment 3

[0078] Except 2) preparation process of polypropylene and polyethylene blending and co-extrusion thin material layer: middle,

[0079] Corona layer: 70KgRC1314 (co-PP); 30KgSP1520; 30Kg150BW; 0.8Kg100991-k

[0080] Middle layer: 25KgF920A; 35Kg1018FA; 38Kg2426H; 22Kg white female F501; 0.3Kg100991-k;

[0081] Heat seal layer: 30Kg Yanshan 100AC; 25Kg1002KW; 30Kg5100G; 2.0KgSE07PE; 1.5KgAB-20LD; 0.4Kg100991-k;

[0082] 3) In the extrusion compounding process,

[0083] The weight ratio of LDPE 1C7A to SP1071C is 1:3.5

[0084] Outside, all the other are identical with embodiment 1.

[0085] The technical index of embodiment 1-3 is as follows:

[0086]

[0087]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com