Process for producing sulfadimidine

A technology for sulfamethazine and production process, applied in the field of sulfamethazine production technology, can solve the problems of waste of raw materials, increase of raw material costs, waste of tail gas hydrogen chloride and no recycling and utilization, etc., so as to reduce neutralization costs, ensure quality and process The effect of conditional optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

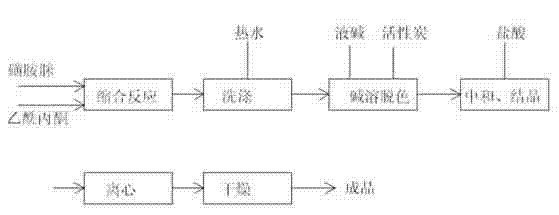

[0011] figure 1 A kind of sulfamethazine production technology shown in , take sulfamidine and acetylacetone as raw material, carry out condensation reaction in the first step, make wet product sulfamethazine after condensation, the second step washes with hot water and makes wet Product sulfamethazine, remove other incidentals in the reaction solvent, the 3rd step, add gac and liquid caustic soda in the sulfamethazine after washing and carry out alkali-soluble decolorization treatment, the 4th step, for the sulfamethazine after the decolorization The liquid caustic soda taken out of the pyrimidine is neutralized with an acidic solvent, and then crystallized. In the fifth step, the crystallized sulfamethazine is separated out by centrifugal analysis and dried to obtain a finished product, which is characterized in that: the neutralization 1. In the crystallization step, the neutralization of the acidic solvent used is hydrochloric acid neutralization.

[0012] In order to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com