Double-component silane-terminated sealing adhesive and preparation method thereof

A silane-terminated, sealed and bonded technology, applied in the direction of adhesives, polyether adhesives, chemical instruments and methods, etc., to achieve the effect of flexible ratio range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

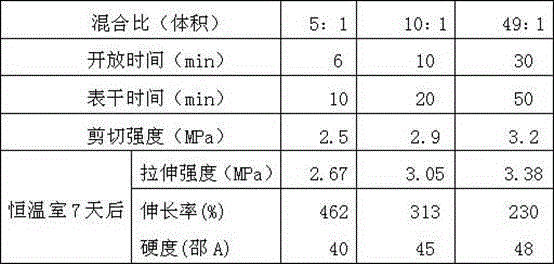

Examples

Embodiment 1

[0084] Component A:

[0085] Preparation of a one-component silane-modified polyether sealant containing silane-terminated polymer, plasticizer (dioctyl phthalate), calcium carbonate, titanium dioxide, fumed silica, modified organotin for curing agent, etc., the parts by weight ratio of the composition is as follows:

[0086] Silane-terminated polymer 38.5 parts

[0087] Dioctyl phthalate 13.3 parts

[0088] Calcium carbonate 40.2 parts

[0089] Titanium dioxide 4.1 parts

[0090] 0.5 parts of polyamide thixotropic agent

[0091] UV absorber 0.15 parts

[0092] UV stabilizer 0.15 parts

[0093] Fumed silica 2.2 parts

[0094] Vinyltrimethoxysilane 0.3 parts

[0095] N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane 0.5 parts

[0096] Modified organotin 0.1 parts

[0097] During preparation, after adding silane-terminated polymers, dioctyl phthalate, titanium dioxide, ultraviolet absorbers and stabilizers sequentially into a biaxial planetary stirring tank at room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com