Re-combustion injector of combustor of re-combustion supercritical pressure gas-liquid phase fuel generator

A technology of fuel generators and injectors, which is applied in the direction of burners, production fluids, wellbore/well components, etc., and can solve the design concept of simultaneous combustion of gas-liquid two-phase fuels and the inability to satisfy two-phase fluid injection at the same time Characteristic requirements, the inability to change the combustion mode of the generator, etc., to achieve the effect of avoiding burning and damage, flexible cooling mode and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

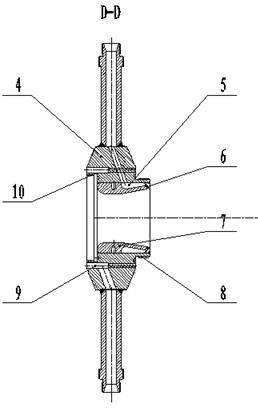

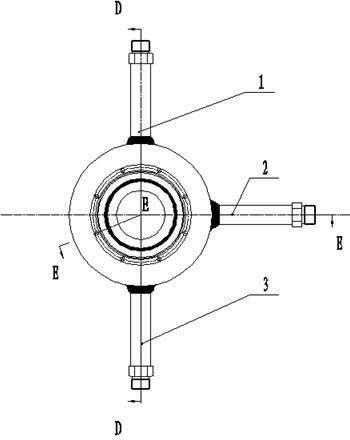

[0038] like figure 1 , figure 2 , image 3 As shown, the components in the figure are: gas phase nozzle 1, liquid phase nozzle 2, water nozzle 3, afterburning injector housing 4, and throat liner 7.

[0039] Wherein, a gas phase cavity 5 and a gas phase nozzle 6 are provided in the internal channel of the gas phase connector 1, a fuel nozzle 11 is provided in the internal channel of the liquid phase connector 2, and a liquid collecting chamber 9 and a liquid collecting chamber 9 are provided in the internal channel of the water connector 3. The water hole 13; the two end faces of the afterburner injector housing 4 are spherical end faces 15, and its front end has an internal connecting thread 10 and a corresponding sealing groove for connecting the air and water combination redundant cooling jacket assembly of the pre-combustion chamber 12. Its rear end has an external connection thread 8 and a sealing groove 14 for connecting the water cooling jacket of the supplementary c...

Embodiment 2

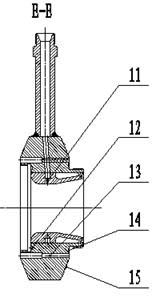

[0043] like Figure 4 , Figure 5 or Image 6 , Figure 7 As shown, the components in the figure are: gas phase nozzle 1 or liquid phase nozzle 2, water nozzle 3, afterburning injector housing 4, throat liner 7.

[0044] Among them, the afterburning injector shell 4 is provided with a water connection nozzle 3, a gas phase connection nozzle 1 or a liquid phase connection nozzle 2, and a gas phase chamber 5 and a gas phase nozzle 6 or a liquid phase connection nozzle are provided in the internal passage of the gas phase connection nozzle 1. A fuel nozzle 11 is provided in the inner passage of the nozzle 2, and a liquid collection chamber 9 and a water passage hole 13 are provided in the inner passage of the water joint nozzle 3; the two end faces of the afterburning injector housing 4 are spherical end faces 15, and Its front end has an internal connecting thread 10 and a corresponding sealing groove 12 for connecting the air and water combined redundant cooling jacket assem...

Embodiment 3

[0048] like Figure 8 , Figure 9 or Figure 10 , Figure 11 As shown, the components in the figure are: gas phase nozzle 1 or liquid phase nozzle 2, afterburning injector housing 4, throat liner 7.

[0049] Among them, the afterburning injector housing 4 is provided with a gas-phase nozzle 1 or a liquid-phase nozzle 2, and the internal passage of the gas-phase nozzle 1 is provided with a gas-phase chamber 5 and a gas-phase nozzle 6, and the internal passage of the liquid-phase nozzle 2 A fuel nozzle 11 is provided in the middle, and a liquid collecting chamber 9 and a water hole 13 are provided on the supplementary combustion injector housing 4; the two end surfaces of the supplementary combustion injector housing 4 are spherical end surfaces 15, and its front end has The internal connection thread 10 and the corresponding sealing groove 12 connected to the air and water combination redundant cooling jacket assembly of the pre-combustion chamber have an external connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com