Deep sea vertical pipe array model vortex-induced vibration test device with top capable of moving in step flow

A deep-sea riser and vortex-induced vibration technology, applied in the field of marine engineering, can solve the problems of less test data, unavoidable scale effect, and small test section distance, and achieve convenient installation and disassembly, avoid scale effect, and real external environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

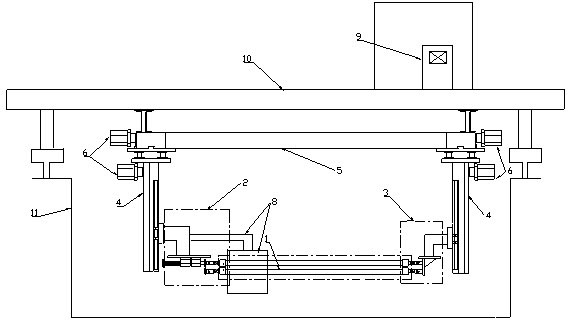

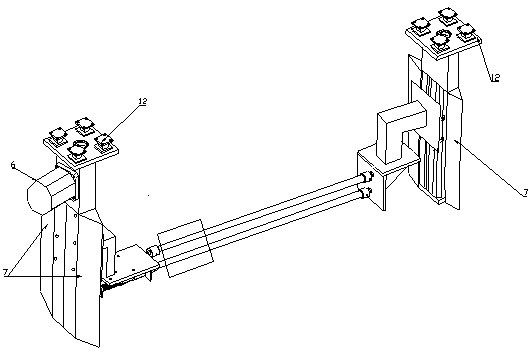

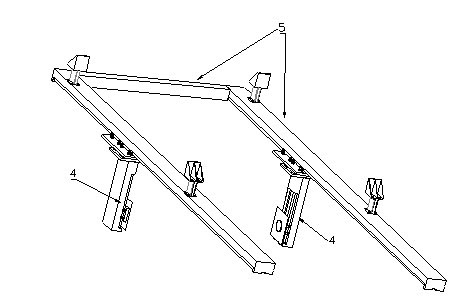

[0049] Such as figure 1 As shown, this embodiment includes: several deep-sea riser modules 1, a top support module 2, a bottom support module 3, two vertical track modules 4, a horizontal track module 5, four motor modules 6, and four fairing modules 7 , the sleeve module 8 and the measurement analysis control module 9, wherein: two vertical track modules 4 are respectively connected with the bottom of the horizontal track module 5, the top support module 2 and the bottom support module 3, and the horizontal track module 5 is connected with the trailer 10 respectively The bottom of the side is connected to the top of two vertical track modules 4, the two ends of several deep-sea riser modules 1 are respectively connected to the top support module 2 and the bottom support module 3, and the fairing side plates 39 of the four fairing modules 7 are respectively Through and fixed on the outside of two vertical track modules 4, there are two fairing modules 7 on each vertical track ...

Embodiment 2

[0067] Such as Figure 14 As shown, when the number of deep-sea riser modules 1 is equal to 2, two deep-sea riser modules 1 are arranged in a vertical array.

Embodiment 3

[0069] Such as Figure 15 As shown, when the number of deep-sea riser modules 1 is equal to 3, two deep-sea riser modules 1 are arranged in a triangular array.

[0070] Such as figure 1 As shown, the trailer 10 and the towing pool 11 are existing test facilities. The trailer 10 can realize bidirectional uniform linear motion at different speeds. environment, the relative movement of the two can simulate the step flow of different flow velocities.

[0071] The device has the following advantages: 1. The device can be installed with a large-scale riser model 15, thereby avoiding the scale effect; 2. The device can make full use of the high speed of the trailer 10 to simulate the real Reynolds number vortex-induced vibration of the large-scale riser model 15. 3. The device can make full use of the length of the towed pool 11 to conduct long-distance tests and obtain longer and more stable test data. 4. The device can use the vertical track module and the horizontal track modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com