Copper-clad plate with low-dielectric constant

A technology of copper clad laminate and low dielectric is applied in the field of copper clad laminate modified by hollow glass microspheres, which can solve the problems of limiting the application of integrated circuits, improving thermal stability, reducing the polarity of the material itself, and achieving good chemical resistance. High performance, cost-effective, good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

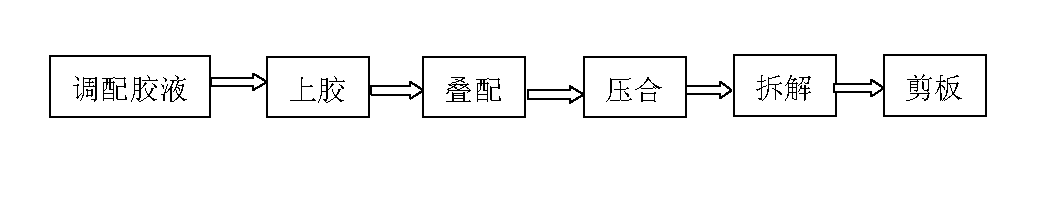

[0034]refer to figure 1 , a low-dielectric copper-clad laminate prepared by the following method:

[0035] 1.1) Add 5kg of hollow glass microspheres with a particle size of 900 mesh, 10kg of dimethylformamide, 0.5kg of silane coupling agent, and 0.05kg of fluorocarbon surfactant into a high-speed disperser and stir at high speed;

[0036] 1.2) Mix 125kg of bisphenol A epoxy resin, 3.1kg of electronic grade dicyandiamide, 0.1kg of dimethylimidazole, and 28kg of dimethylformamide to form a glue solution with a gel time of 210-215 seconds;

[0037] 1.3) Add the glue solution in step 1.2) to the hollow glass microsphere solution stirred at high speed in step 1.1) and mix at high speed to form a mixed solution;

[0038] 2) Immerse the 2116 cloth in the mixed solution pumped into the rubber basin, put it into an oven at a temperature of 150°C to 230°C, bake it, and then cool it to obtain a resin fluidity of 22% to 23%, and a content of 48.4 %~49.4% 2116 cloth prepreg, cut the 2116...

Embodiment 2

[0044] refer to figure 1 , a low-dielectric copper-clad laminate prepared by the following method:

[0045] 1.1) Add 10kg of hollow glass microspheres with a particle size of 300 mesh, 22kg of dimethylformamide, 0.6kg of silane coupling agent, and 0.05kg of fluorocarbon surfactant into a high-speed disperser and stir at high speed;

[0046] 1.2) Mix 125kg of bisphenol A epoxy resin, 2.8kg of electronic grade dicyandiamide, 0.055kg of dimethylimidazole, and 28kg of dimethylformamide into a glue solution with a gel time of 245-250 seconds;

[0047] 1.3) Add the glue solution in step 1.2) to the hollow glass microsphere solution stirred at high speed in step 1.1) and mix at high speed to form a mixed solution;

[0048] 2) Immerse the 1506 cloth in the mixed liquid pumped into the rubber basin, put it into an oven at a temperature of 150°C to 230°C, bake it, and then cool it to obtain a resin fluidity of 18% to 19%, and a content of 42.3 %~42.7% 1506 cloth prepreg, cut the 1506 ...

Embodiment 3

[0054] refer to figure 1 , a low-dielectric copper-clad laminate prepared by the following method:

[0055] 1.1) Add 15kg of hollow glass microspheres with a particle size of 1200 mesh, 20kg of dimethylformamide, 1kg of silane coupling agent, and 0.07kg of fluorocarbon surfactant into a high-speed disperser and stir at high speed;

[0056] 1.2) Mix 125kg of bisphenol A epoxy resin, 2.5kg of electronic grade dicyandiamide, 0.050kg of dimethylimidazole, and 26kg of dimethylformamide to form a glue with a gel time of 260-270 seconds;

[0057] 1.3) Add the glue solution in step 1.2) to the hollow glass microsphere solution stirred at high speed in step 1.1) and mix at high speed to form a mixed solution;

[0058] 2) Immerse the 2116 cloth in the mixed solution pumped into the rubber basin, put it into an oven at a temperature of 150°C to 230°C, bake it, and then cool it to obtain a resin fluidity of 20% to 21%, and a content of 46.5 %~47.3% 2116 cloth prepreg, cut the 2116 cloth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com