Two-dimensional comb actuator and manufacturing method thereof

A manufacturing method and actuator technology, which are applied in the manufacture of microstructure devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of improper lateral overcut of component layers, The actuator is difficult to start and other problems, to achieve the effect of solving the lateral overcut, solving the difficulty of starting, and increasing the rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The preferred embodiments of the present invention are described in detail by the accompanying drawings and the following descriptions. In different drawings, the same reference numerals represent the same or similar components.

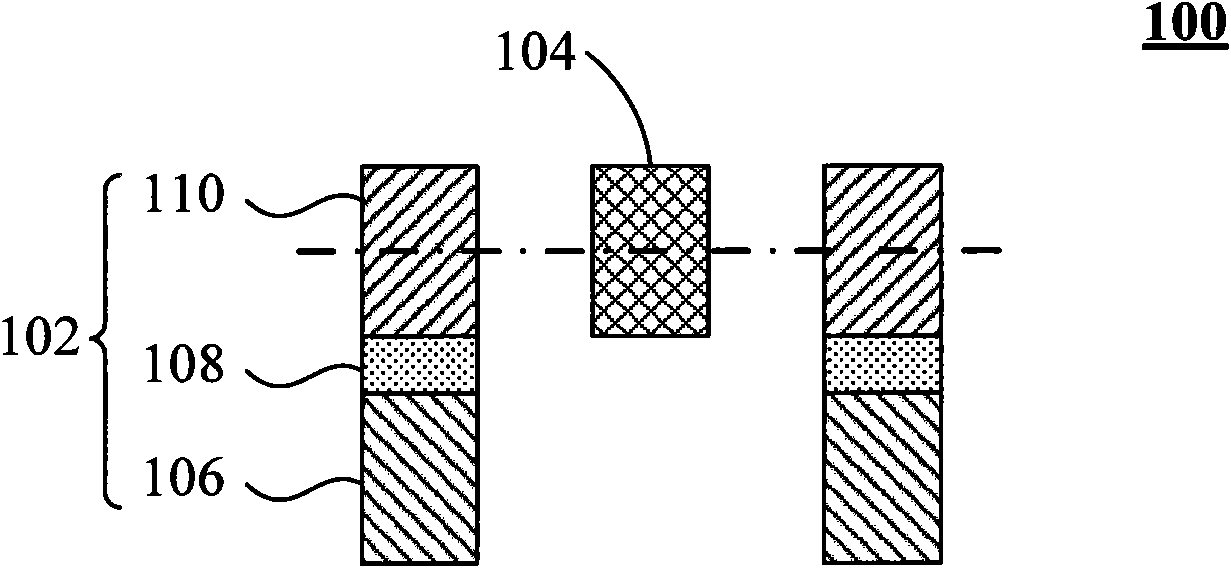

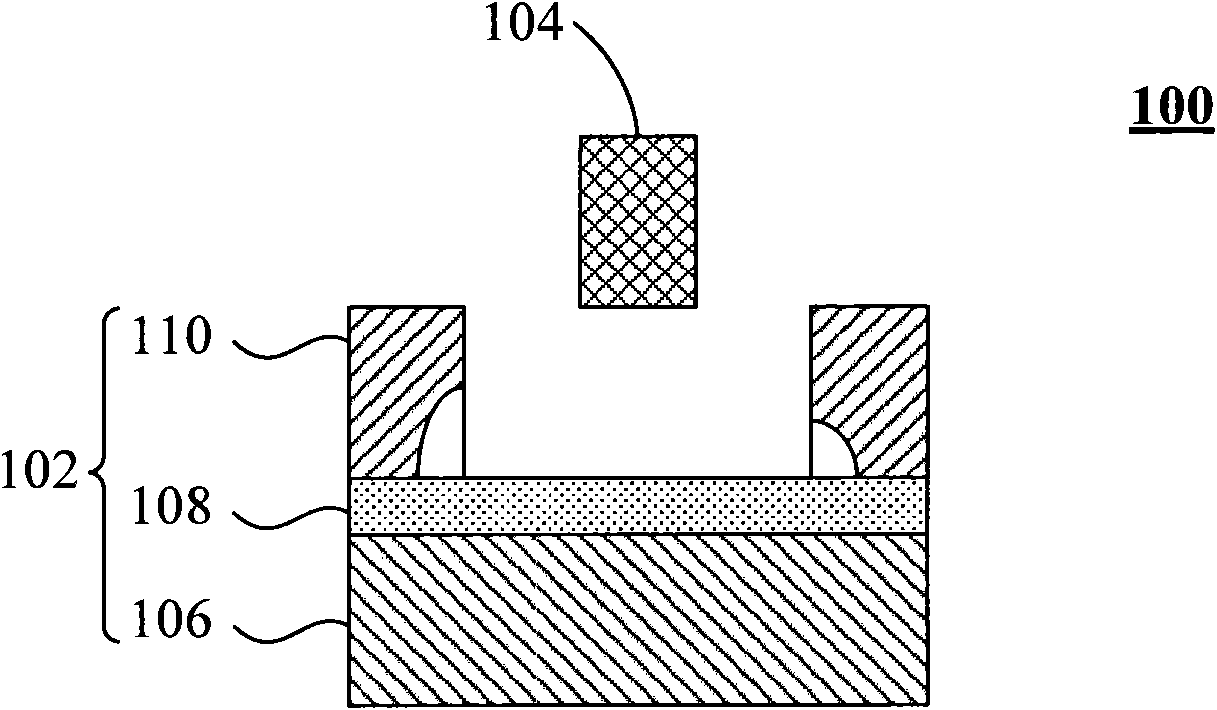

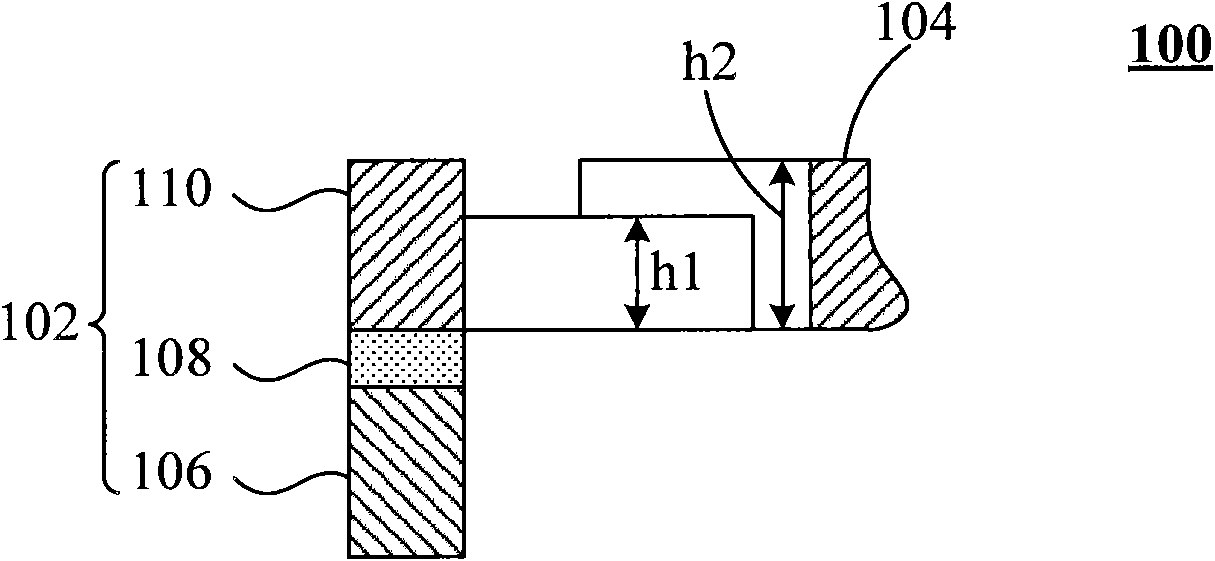

[0054] refer to Figure 2A , which shows a top view of the two-dimensional comb actuator 200 according to an embodiment of the present invention. The two-dimensional comb actuator 200 is suitable for Micro Electro Mechanical Systems (MEMS), and mainly includes a supporting base 202 , a frame 204 and a movable body 206 . The support base 202 is provided with two sets of first comb-shaped electrodes (208a, 208b).

[0055] The frame 204 is attached to the support base 202 by a first torsion bar (torsion bar) 215a for rotation around a first rotation axis 210a, wherein the frame 204 has two sets of internal comb-shaped electrodes (212a, 212b) And two sets of external comb-shaped electrodes (214a, 214b), the two sets of external comb-shaped elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com