Integrated solar energy tile and manufacturing method thereof

A manufacturing method and solar technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, building construction, etc., can solve the problems of complex roof tile structure and increase manufacturing cost, and achieve the effect of simple structure and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

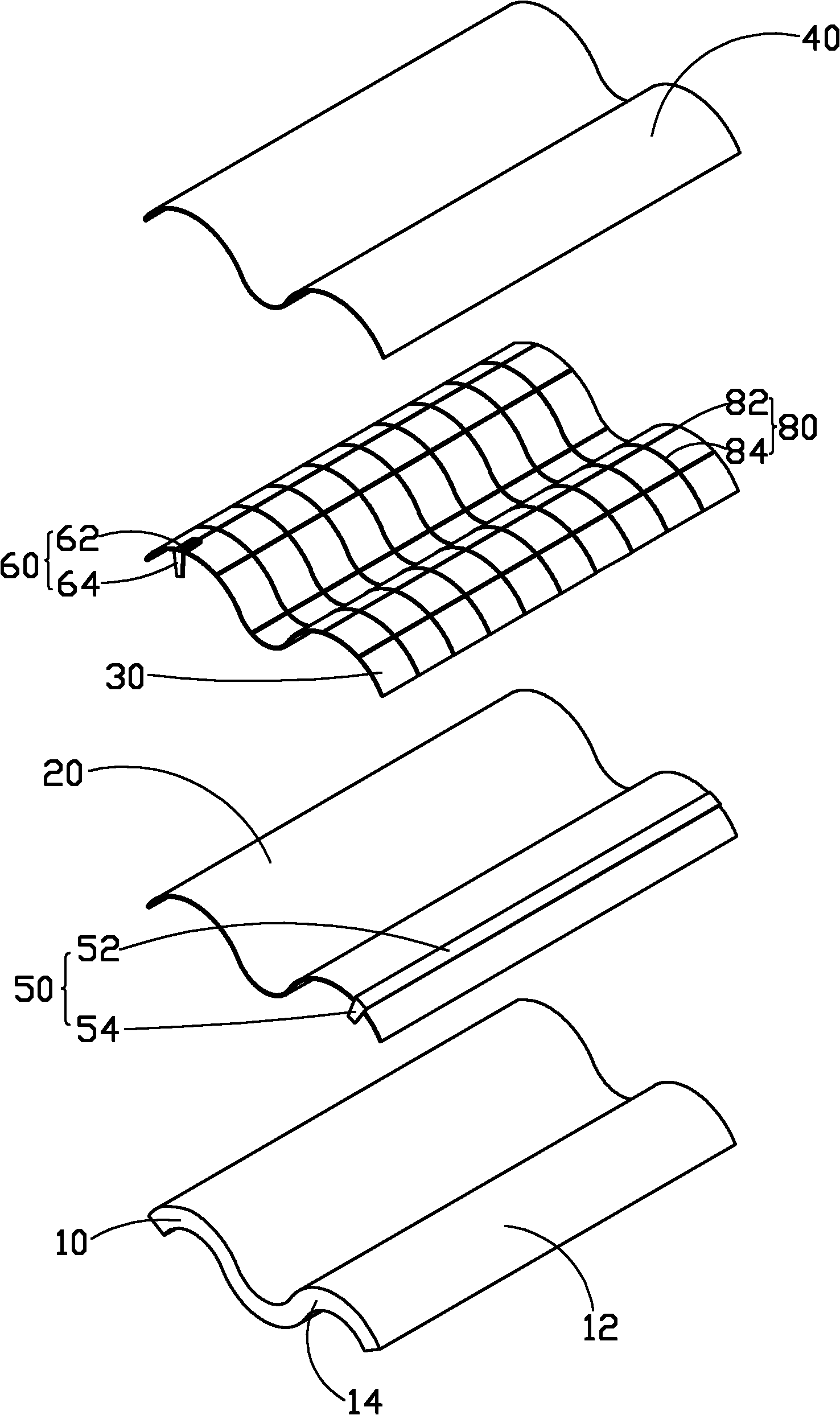

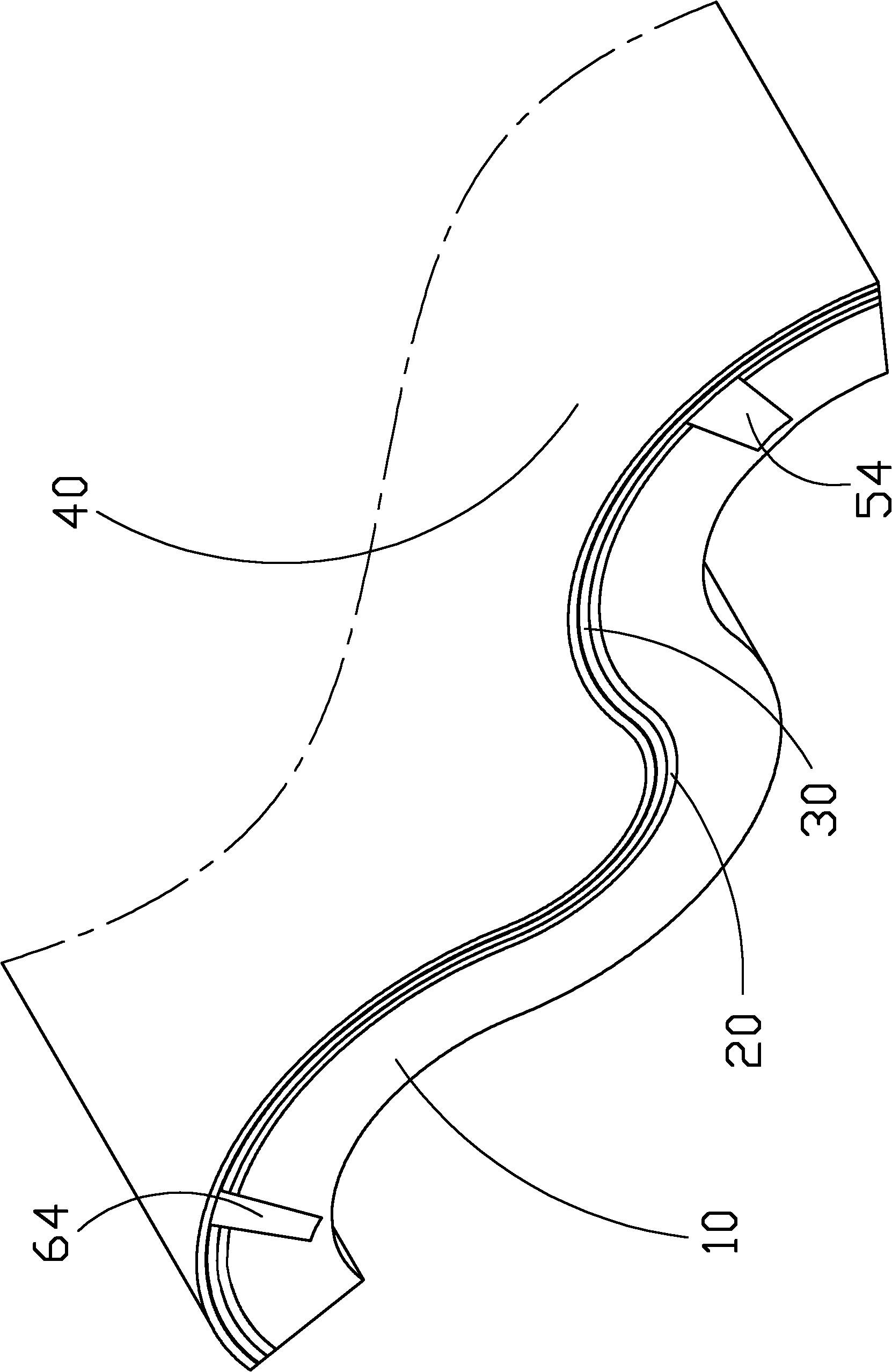

[0032] see figure 1 and figure 2 , an integrated solar tile in one embodiment of the present invention includes a curved tile body 10, a silicon nitride (SiN) film 20, a first contact electrode 50, an amorphous silicon (amorphous silicon) film 30, a second contact electrode 60 . The metal wire layer 80 and the protective film 40 . The curved tile body 10 includes a top surface 12 and a side surface 14 . The silicon nitride film 20 covers the top surface 12 of the curved tile body 10 .

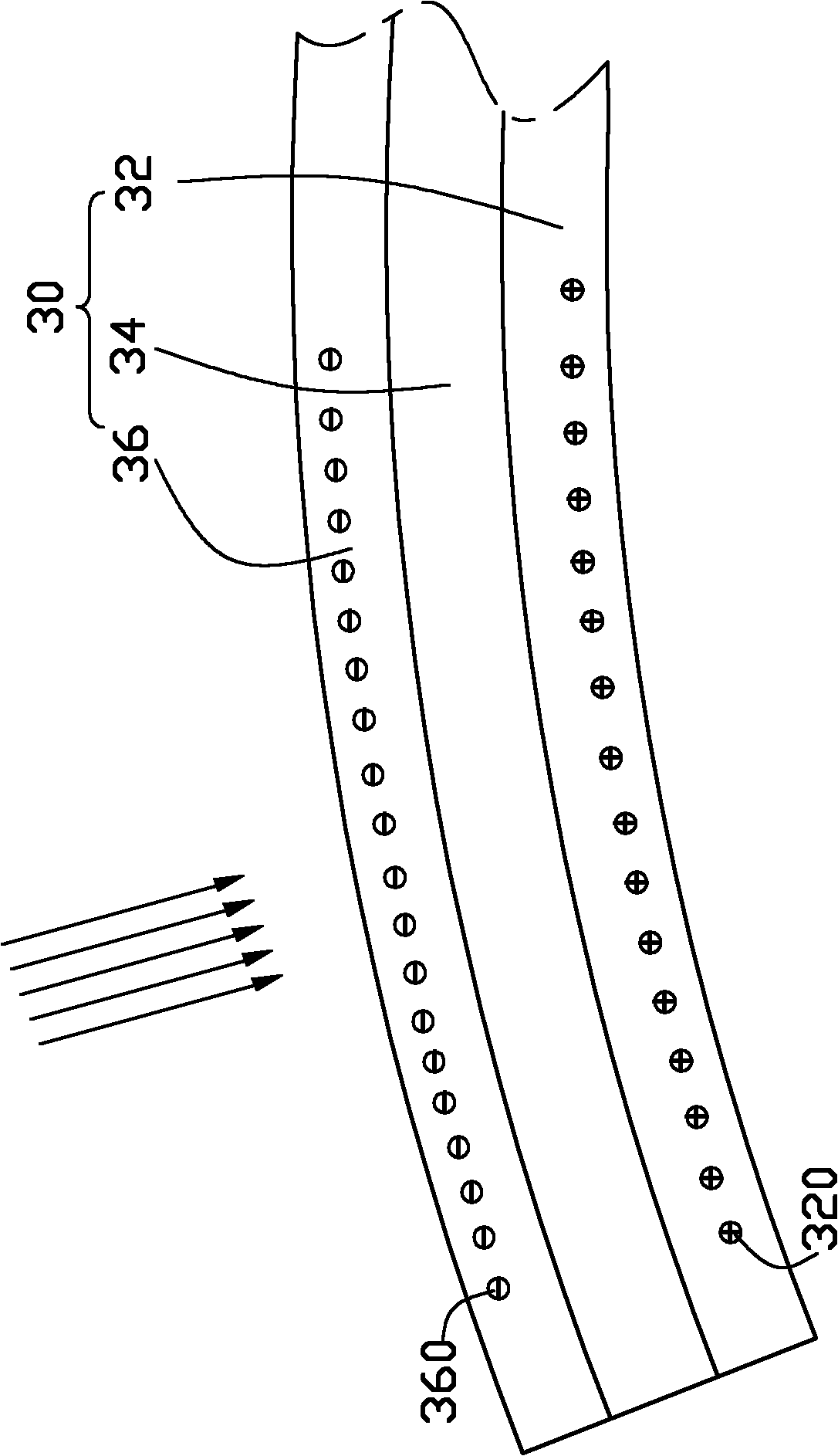

[0033] The first contact electrode 50 is attached to the surface of the silicon nitride film 20 . The first contact electrode 50 includes a first body portion 52 and a first end portion 54, the first body portion 52 is elongated and penetrates the silicon nitride film 20, and the first end portion 54 is vertically arranged It is located at one end of the first body portion 52 and extends to the side surface 14 of the curved tile body 10 . The amorphous silicon film 30 covers the silicon n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com