Laser speckle detection device and method for tire of engineering machine

A laser speckle, engineering machinery technology, applied in measurement devices, automotive tire testing, optical testing flaws/defects, etc., can solve problems such as tire deformation, reduce occupied space, save inspection and processing costs, and achieve clear and accurate images. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

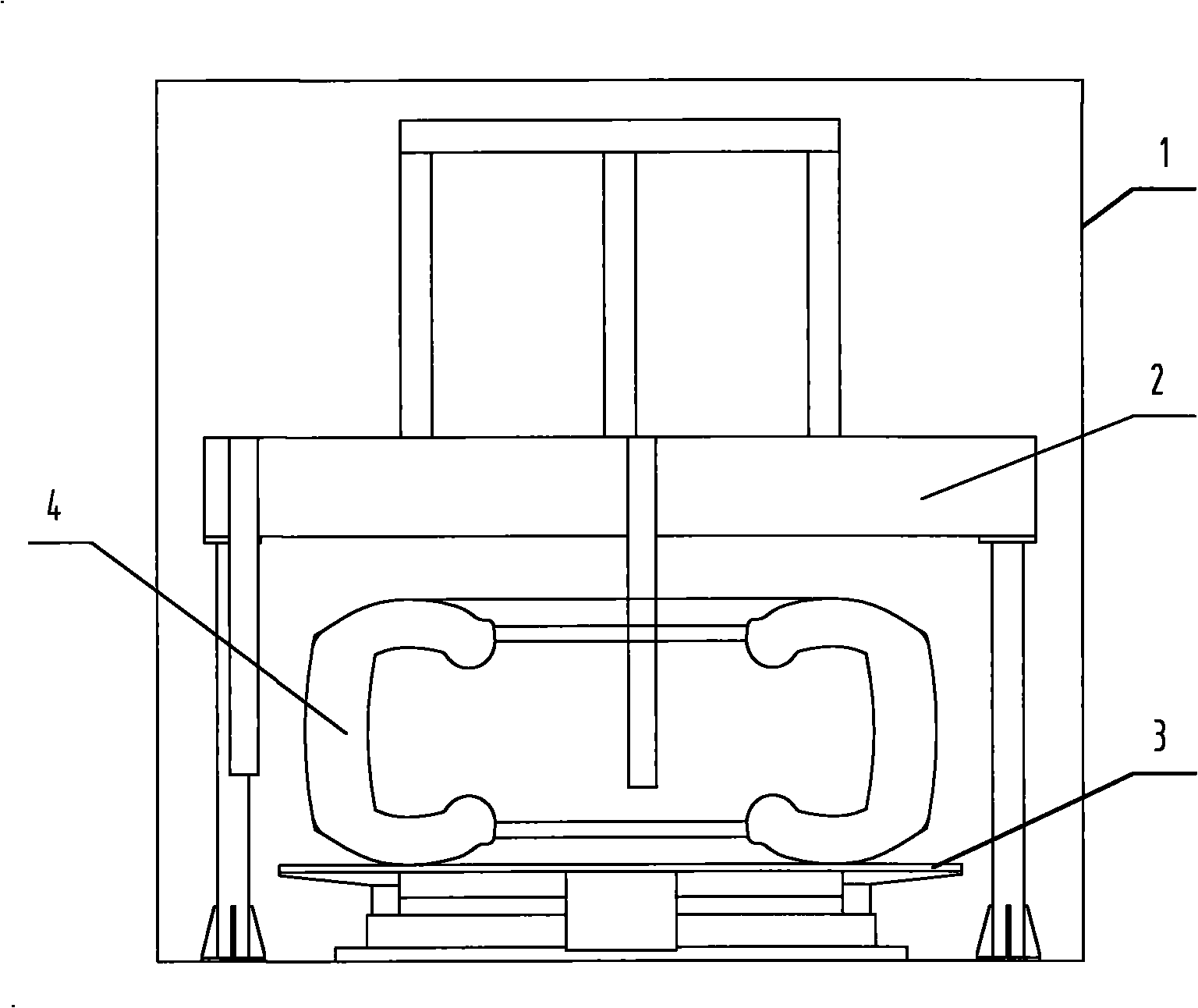

[0063] Example 1, as Figure 1 to Figure 5 As shown, the laser speckle detection device for construction machinery tires mainly includes a vacuum device 1 for forming a negative pressure detection environment,

[0064] The testing device 2 and the rotating device 3 are provided inside the vacuum device 1 . in,

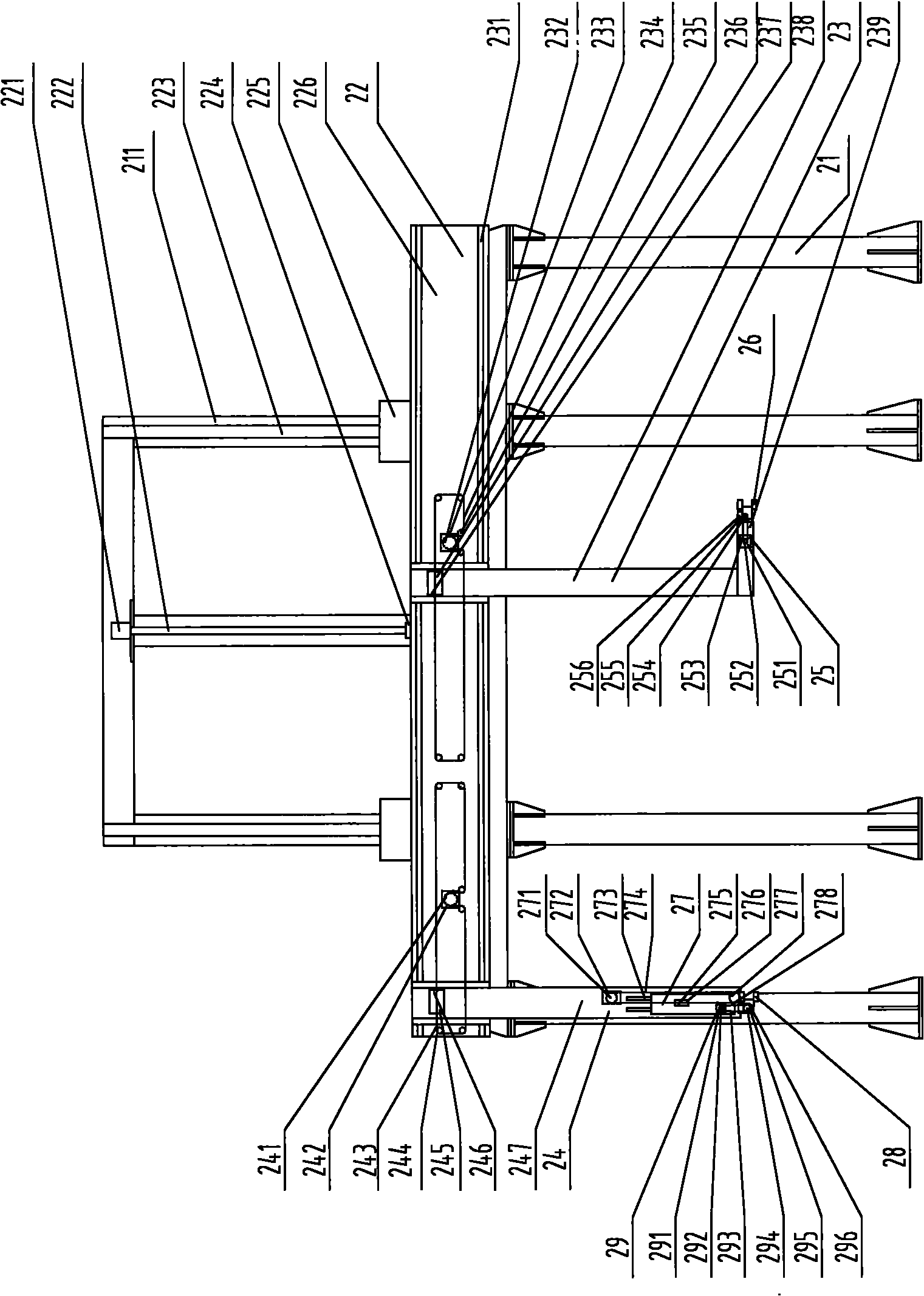

[0065] The testing device 2 is used for taking phase pictures on the inside and outside of the tested tire 4 respectively, and it has an inner probe 26 and an outer probe 28 that can be moved and positioned in the vertical and horizontal directions.

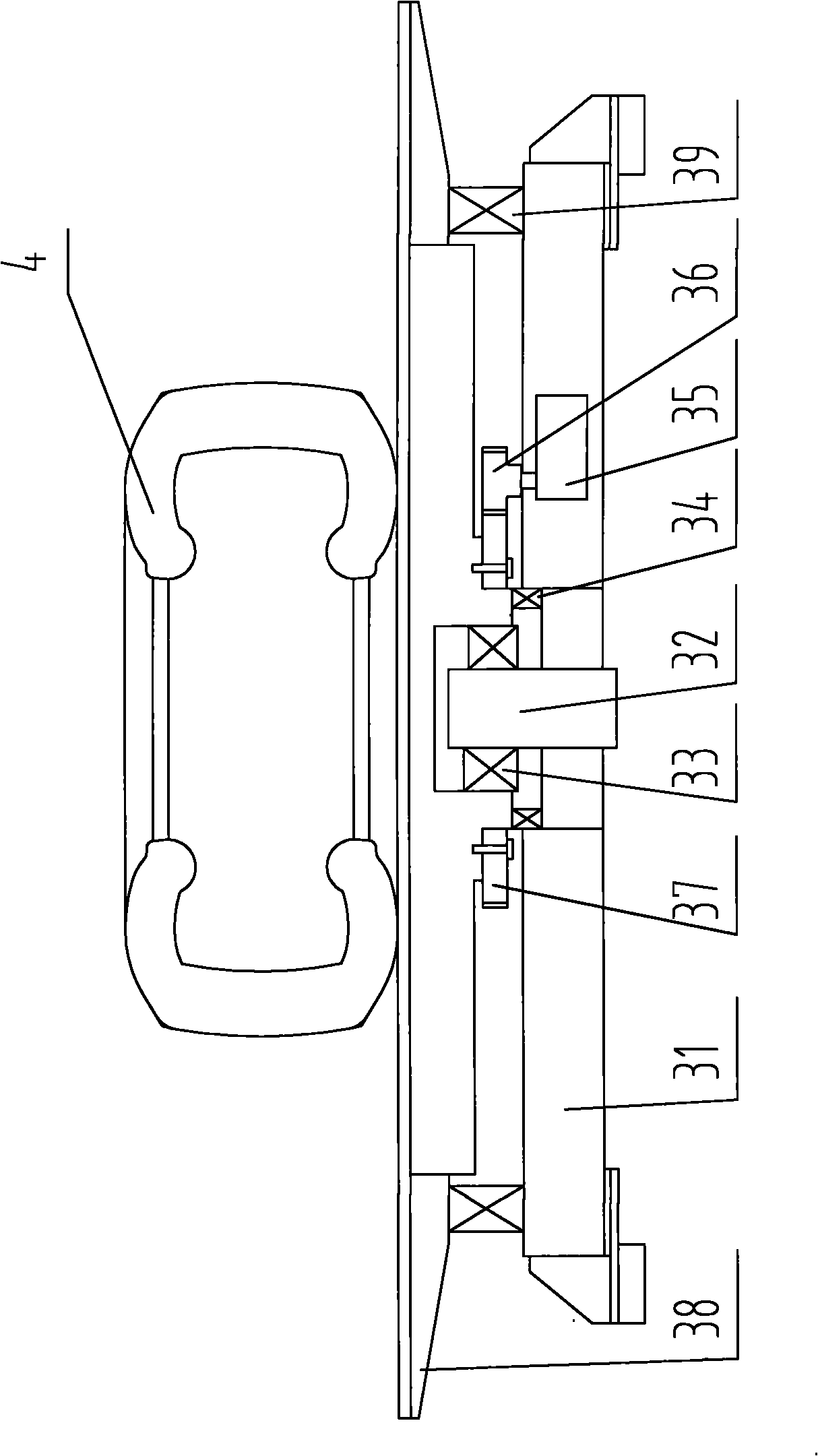

[0066] The rotating device 3 is used to carry and drive the detected tire 4 to rotate synchronously.

[0067] The vacuum device 1 is composed of a vacuum chamber 11 and a vacuum pump 12 connected and composed, and the vacuum chamber 11 adopts a steel frame structure. The vacuum chamber 11 is also provided with a tire loading door 13 and two automatic pressure relief devices 14, and a control valve can be used to contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com