Testing device and testing method

一种测试设备、测试方法的技术,应用在测试船建造、测试介电强度、单个半导体器件测试等方向,能够解决设备变复杂、测试设备复杂等问题,达到减小负担的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

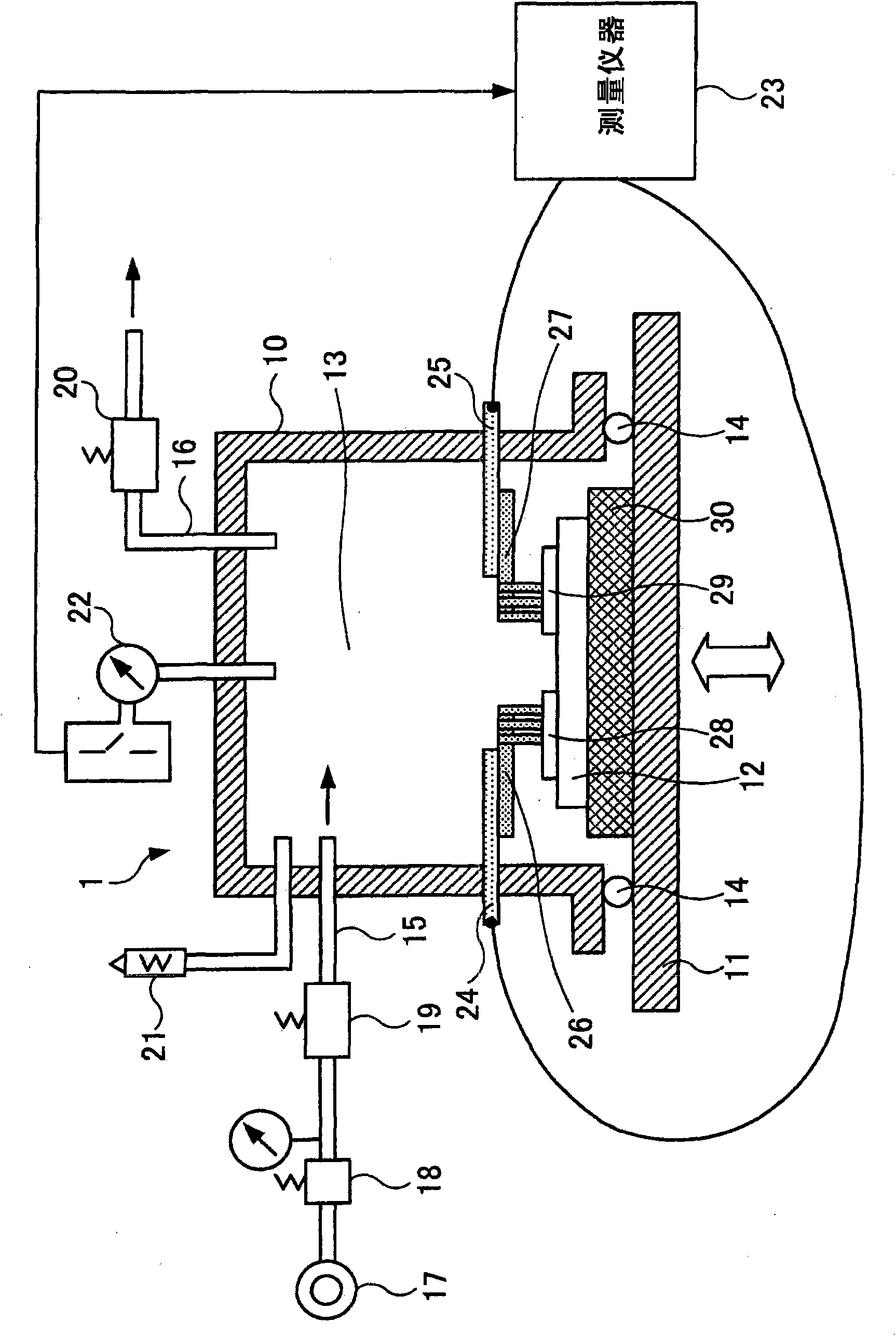

[0034] figure 1 is a diagram showing an example of the testing device according to the first embodiment.

[0035] The testing device 1 has a pressure vessel 10 , a bottom plate 11 , and a measuring instrument 23 . The pressure vessel 10 has an internal space 13 and can withstand a pressure to bring the internal space 13 to a predetermined pressure, and a device under test (DUT) 12 is tested in the internal space 13 . The pressure vessel 10 may also be referred to as, for example, a chamber. Here, it is assumed that the device under test 12 is a semiconductor device including the electrodes 28 and 29 as an example. The device under test 12 may also be any one of a semiconductor wafer, a semiconductor chip, a semiconductor package, or a semiconductor module. The test apparatus 1 may also be configured to appropriately use a configuration of a wafer detector, a processor, and the like according to the apparatus under test 12 as needed.

[0036] The bottom plate 11 is provided...

no. 2 example

[0079] Figure 4 is a diagram showing an example of a test device according to the second embodiment.

[0080] The difference between the test device 2 and the test device 1 lies in the shape of the pressure vessel, and a piston 31 and a servo motor 32 are additionally provided. In addition, although a safety valve is not provided, a safety valve may be provided. Other configurations are the same as those of the test device 1 .

[0081] The pressure vessel 33 has an opening at its top. The piston 31 is arranged to block the opening of the pressure vessel 33 . A servo motor 32 is provided on the piston 31 . The piston 31 raises or lowers the inner space 34 of the pressure vessel 33 under the control of the servo motor 32 .

[0082] At this time, the piston 31 moves along the inner wall 35 of the pressure vessel 33 while being in close contact with the inner wall 35 of the pressure vessel 33 . That is, the pressure vessel 33 functions as an air cylinder. The control of th...

no. 3 example

[0123] Figure 7 A and Figure 7 B is a diagram showing an example of a dielectric strength test according to the third embodiment. Figure 7 A is a top view of the device under test 40, and Figure 7 B is a cross-sectional view of the device under test 40 to which test electrodes 47a and 47b are attached.

[0124] Such as Figure 7 As shown in A, the device under test 40 has a frame electrode 41 , a plurality of lead terminals 42 and 43 , and a semiconductor chip 44 . A semiconductor chip 44 is formed on the frame electrode 41 , and the semiconductor chip 44 is electrically connected to the lead terminals 42 and 43 through an internal wire 45 . Furthermore, the frame electrode 41 , the plurality of lead terminals 42 and 43 , the semiconductor chip 44 , and the internal wire 45 are sealed with a resin 46 . Here, an end portion of the frame electrode 41 and an end portion of each of the lead terminals 42 and 43 are exposed from the resin 46 .

[0125] When testing, clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com