Liquid crystal display module and liquid crystal display panel

A liquid crystal display module, display panel technology, applied in static indicators, printed circuits, instruments, etc., can solve the problems of reduced welding accuracy, welding dislocation, etc., and achieve the effect of improving welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced.

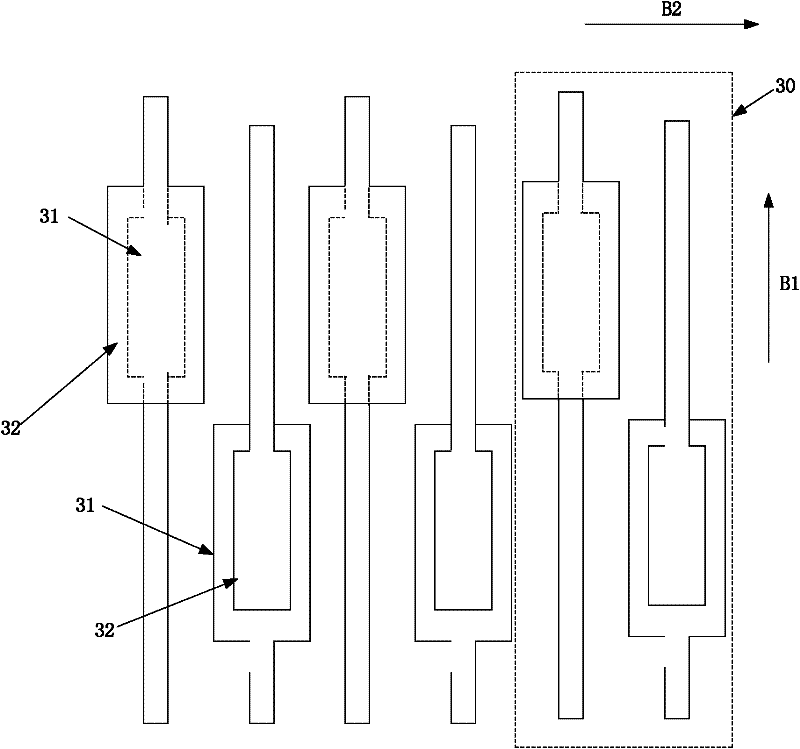

[0034] image 3 A structural diagram of a preferred embodiment of the liquid crystal display module in the present invention is shown.

[0035] see image 3 , the liquid crystal display module includes a display panel (not shown), the display panel is provided with a plurality of panel pads 31, the length of the panel pads 31 extends along the longitudinal direction B1 of the pull wire direction, the mold The set also includes a flexible circuit board (not shown in the figure), and the flexible circuit board includes a plurality of flexible circuit board pads 32 , and the flexible circuit board pads 32 are soldered to the panel pads 31 one by one.

[0036] Please also refer to image 3 and Figure 4 , two adjacent columns of panel pads and corresponding two columns of flexible circuit board pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com