Resin composition for laser engraving, relief printing plate precursor for laser engraving, process for producing relief printing plate and relief printing plate

一种树脂组合物、激光雕刻的技术,应用在凸版印刷版领域,能够解决画质下降、雕刻形状(边缘形状不良、难以去除胶粘性渣滓等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0356] 1. Preparation of resin composition for laser engraving

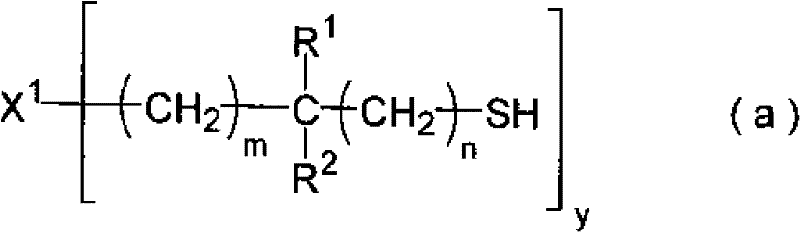

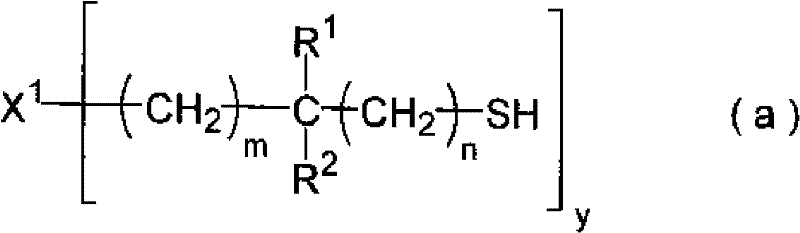

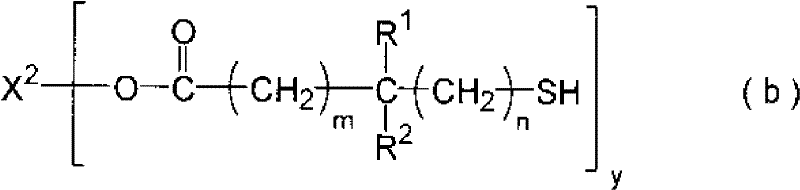

[0357] In a three-necked flask with a stirring blade and a condenser, 40 parts of Denka Butyral #3000-2 (polyvinyl butyral, manufactured by Denka Kogyo Co., Ltd.) as (component C) binder polymer, and ( Component F) 0.75 parts of Ketjenblack EC600JD (F-1) (manufactured by Lion Co., Ltd.) as a photothermal conversion agent, 20 parts of RS-540 (manufactured by ADEKA Co., Ltd.) as a plasticizer, and propylene glycol monomethyl ether acetic acid as a solvent 47 parts of ester were heated at 70° C. for 2 hours while stirring to dissolve the polymer. A-1 (manufactured by Wako Pure Chemical Industries, Ltd., 10.9 parts) as (component A) a compound having at least 2 mercapto groups, and B-4 (Tokyo Chemical Industry Co., Ltd.) as (component B) ethylenically unsaturated compound were added. Co., Ltd., 9.1 parts; component A and component B are equimolar in terms of molar ratio), (component D) silane compound D-1 (KBE-846, ...

Embodiment 2~41、 comparative example 1 and 2

[0363] In Examples 2 to 41 and Comparative Examples 1 and 2, Component A, Component B, Component C, Component D, Component E, and Component F were combined as shown in Table 1, and the same procedure as in Example 1 was performed, A resin composition for laser engraving is prepared, followed by forming a crosslinked relief-forming layer.

[0364] In addition, component A and component B were compounded so that the molar ratios of the mercapto groups and ethylenically unsaturated groups as the respective functional groups were the molar ratios shown in Table 1, and their The total weight is 20 parts. Component C, component D, component E, and component F are the same parts by weight as in Example 1.

[0365] In addition, the compound used as component A is selected from the said exemplified compound.

[0366] The compound used as component B is selected from the above-mentioned Exemplary Compounds B-1 to 22.

[0367] As component C, the following compounds were used.

[036...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com