Composite anode material for lithium sulfur battery, preparation method and application thereof

A composite cathode material, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problems of poor cycle performance of sulfur batteries, and achieve the effect of uniform size and good electrochemical cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

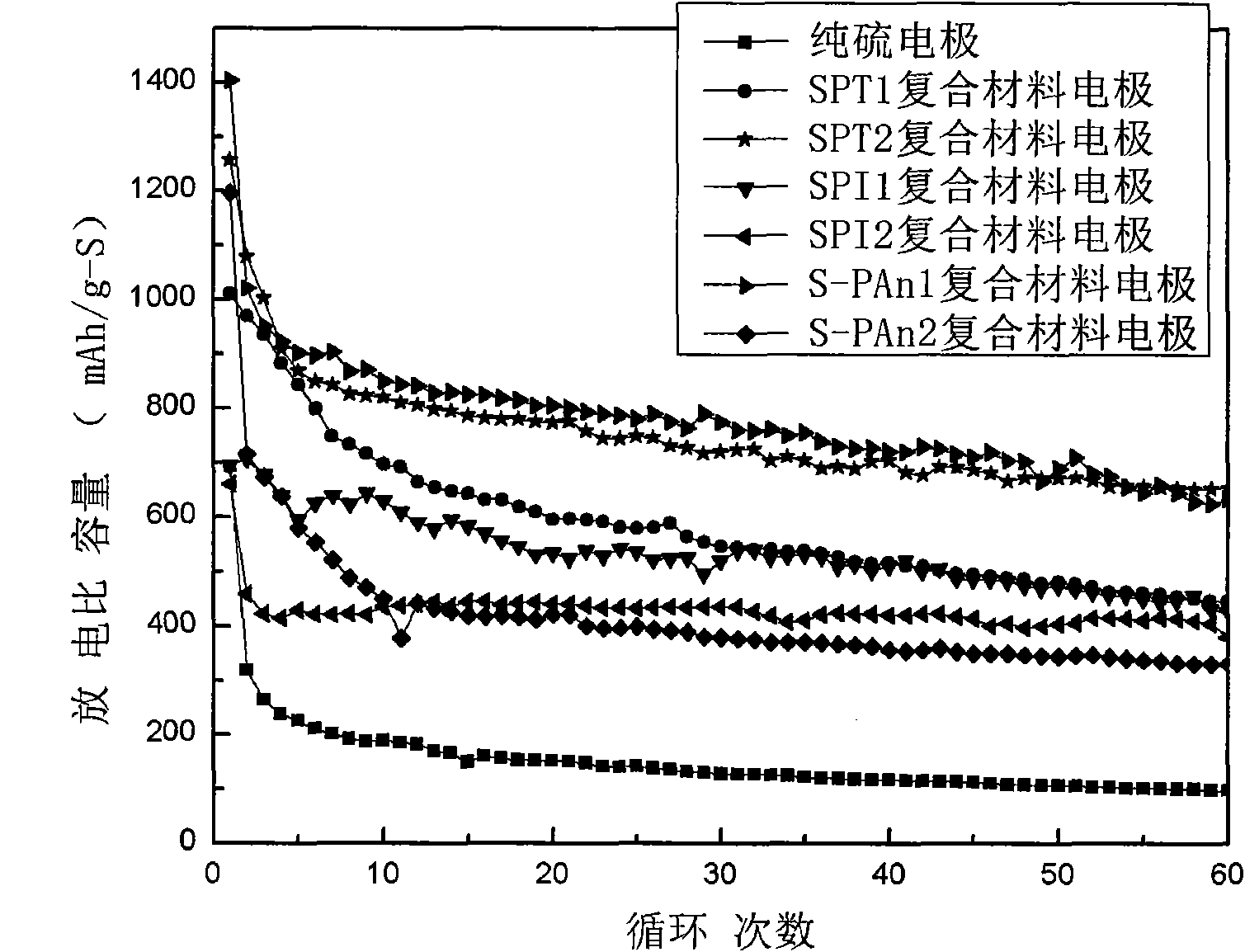

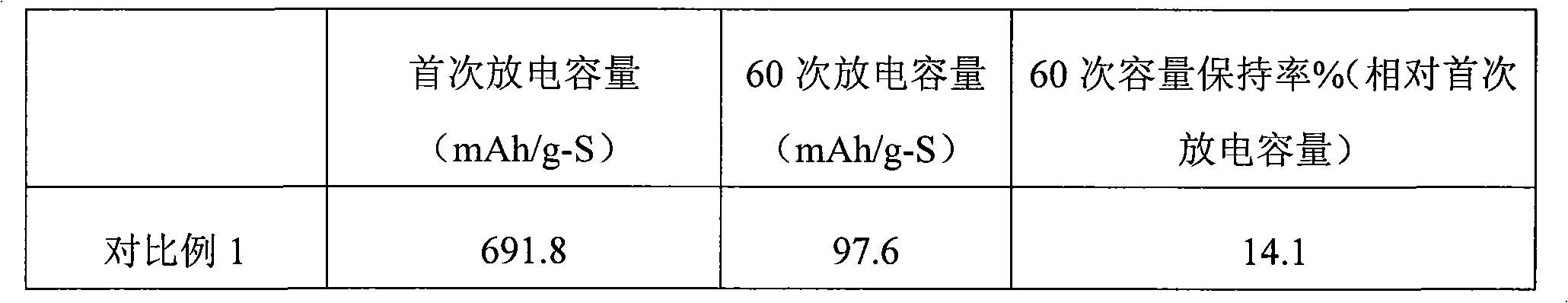

[0036] First, sulfur and polypyrrole were vacuum-dried at 50 °C for 10 h, respectively. Sulfur and polypyrrole were mixed evenly in a mass ratio of 2:1, then vacuum-sealed in a glass container, then kept at 150°C for 4 hours, and cooled naturally to obtain a sulfur-polypyrrole composite material (SPT1 ). The electrode preparation method, battery assembly, and test conditions are the same as in Comparative Example 1. The test results are shown in Table 1.

Embodiment 2

[0038] The drying of raw material is as embodiment 1. Mix sulfur and polypyrrole at a mass ratio of 1:1 and obtain a sulfur-polypyrrole composite material (SPT2) with a sulfur content of 40% according to the method of Example 1. The electrode preparation method, battery assembly, and test conditions are the same as in Comparative Example 1. The test results are shown in Table 1. From the data in Table 1, it can be seen that the cycle performance of the composite electrode has been greatly improved compared with the pure sulfur electrode.

Embodiment 3

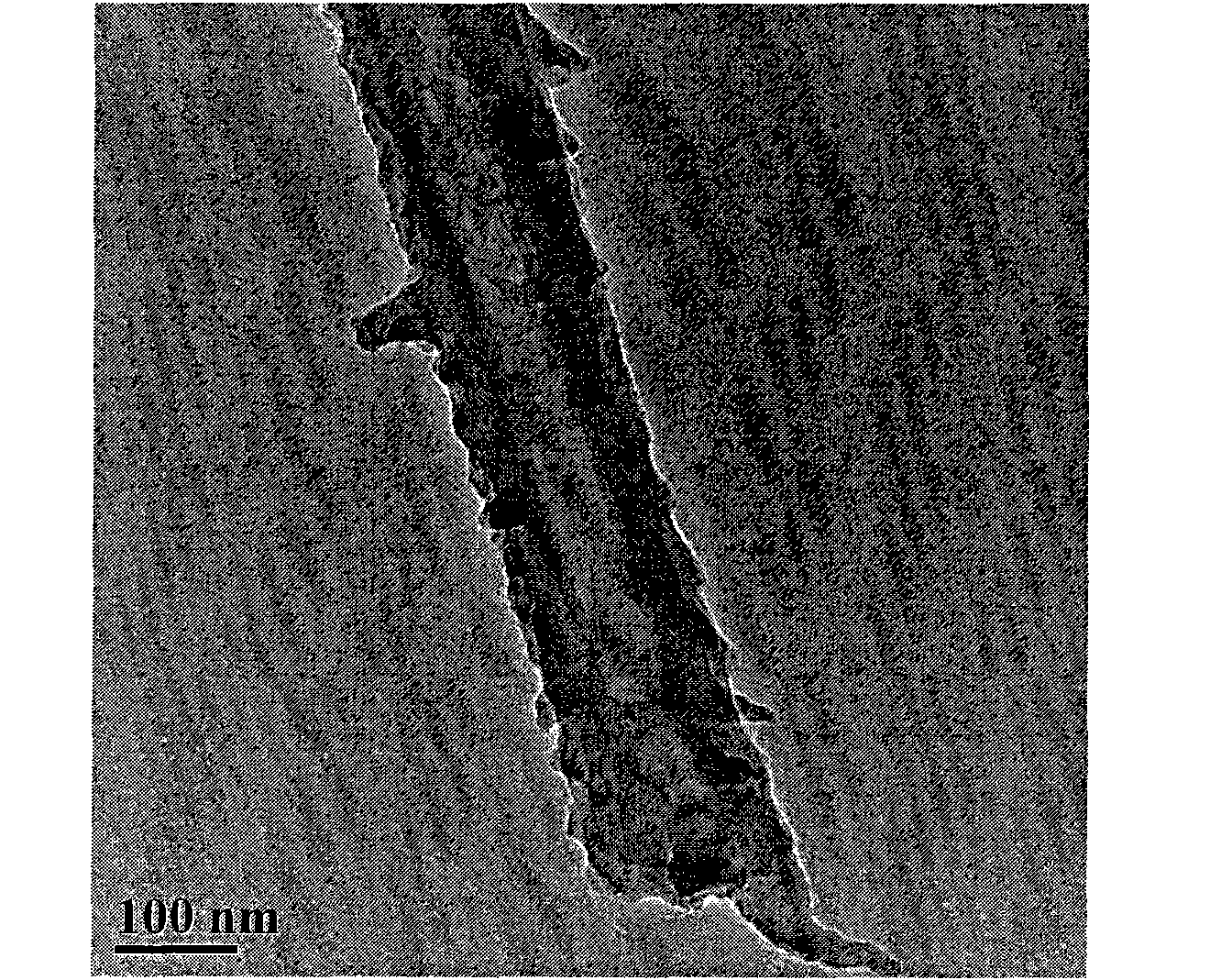

[0040] The drying of raw material is as embodiment 1. Melt sulfur completely at 140°C, rapidly cool it in air or water, then dissolve it in CS 2 After filtration, a filtrate containing 10% sulfur was obtained. Immerse an appropriate amount of polypyrrole nanotubes into the above sulfur CS 2 The solution was stirred for 10 minutes and then left to stand for 20 minutes, and then the filtered product was vacuum-dried at 50° C. to obtain a sulfur-polypyrrole composite material (SPI1) with a sulfur content of 15%. The electrode preparation method, battery assembly, and test conditions are the same as in Comparative Example 1. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap