Isatis root oil microcapsule and functional fabric finishing agent

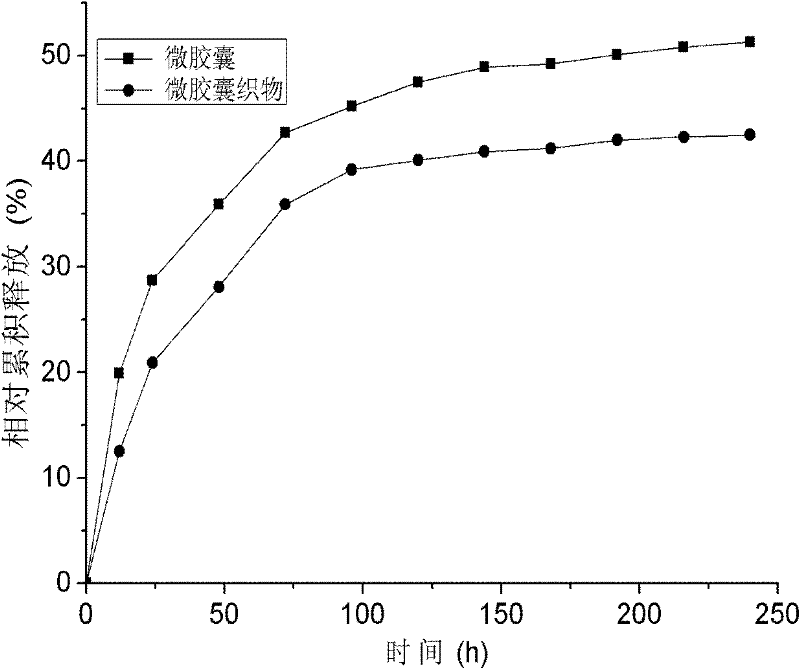

A technology of functional fabrics and Radix isatidis, applied in the direction of biocides, animal repellents, plant growth regulators, etc., can solve the problems of long-term retention of active ingredients, poor affinity with fabric fibers, and reduced comfort of textiles, etc., to achieve good Biocompatibility, improved washing resistance, and prolonged action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

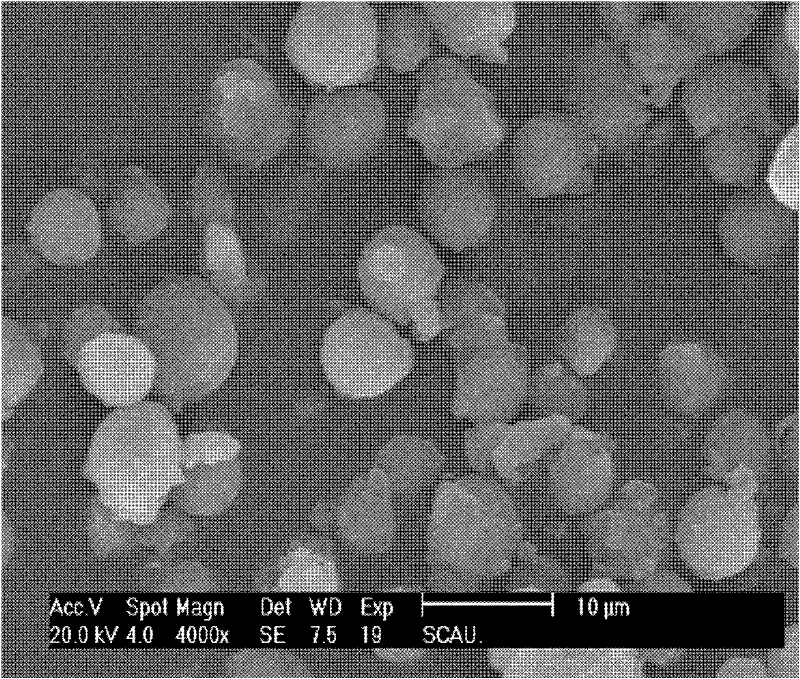

Image

Examples

Embodiment 1

[0071] 1. Preparation of Radix Radix Radix Oil Microcapsule Emulsion

[0072] 1) Dissolve chitosan in 1% (mass fraction) acetic acid solution, adjust the pH of the solution to 8, let stand overnight, filter with suction, put the filter cake in a constant temperature water bath at 75°C, add 4 times the amount of chitosan The isopropanol solution of high quality 2,3-epoxypropyltrimethylammonium chloride, after reacting for 8h, precipitated with absolute ethanol, washed, suction filtered, and dried to obtain chitosan quaternary ammonium salt;

[0073] 2) Dissolve 3g of gelatin in 200mL of 50°C distilled water to prepare a gelatin solution with a concentration of 1.5%;

[0074] 3) dissolving 0.5g chitosan quaternary ammonium salt in 100mL distilled water and preparing a concentration of 0.5% chitosan quaternary ammonium salt solution; adding 1.5g Tween-80 to the chitosan quaternary ammonium salt solution and stirring to dissolve, Add 1.5g Span-80 and 3.5g Radix Radix Radix Oil, a...

Embodiment 2

[0090] 1. Preparation of Radix Radix Radix Oil Microcapsule Emulsion

[0091] 1) Dissolve chitosan in 1% (mass fraction) acetic acid solution, adjust the pH of the solution to 8, let stand overnight, filter with suction, put the filter cake in a constant temperature water bath at 75°C, add 4 times the amount of chitosan The isopropanol solution of high quality 2,3-epoxypropyltrimethylammonium chloride, after reacting for 8h, precipitated with absolute ethanol, washed, suction filtered, and dried to obtain chitosan quaternary ammonium salt;

[0092] 2) Dissolve 2g of gelatin in 200mL of 40°C distilled water to prepare a 1% gelatin solution;

[0093] 3) 0.5g chitosan quaternary ammonium salt is dissolved in 100mL distilled water and is mixed with the chitosan quaternary ammonium salt solution that concentration is 0.5%; In the chitosan quaternary ammonium salt solution, add 1.5g cetyl trimethyl Ammonium chloride was stirred and dissolved, and 5g Radix Radix Radix Oil was added,...

Embodiment 3

[0109] 1. Preparation of Radix Radix Radix Oil Microcapsule Emulsion

[0110] 1) Dissolve chitosan in 1% (mass fraction) acetic acid solution, adjust the pH of the solution to 8, let stand overnight, filter with suction, put the filter cake in a constant temperature water bath at 75°C, add 4 times the amount of chitosan The isopropanol solution of high quality 2,3-epoxypropyltrimethylammonium chloride, after reacting for 8h, precipitated with absolute ethanol, washed, suction filtered, and dried to obtain chitosan quaternary ammonium salt;

[0111] 2) Dissolve 4g of gelatin in 100mL of 40°C distilled water to prepare a 4% gelatin solution;

[0112] 3) Dissolve 0.5g chitosan quaternary ammonium salt in 200mL distilled water to prepare a chitosan quaternary ammonium salt solution with a concentration of 0.25%; add 2g OP-10 to the chitosan quaternary ammonium salt solution and stir to dissolve, add 6g Isatidis oil, emulsified for 10min at a rotating speed of 1500r / min to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wrinkle recovery angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com