Method for the in-line processing of liquid or pasty or semi-liquid media such as grape harvests

A semi-liquid, material technology, applied in the direction of wine preparation, biochemical equipment and methods, liquid injection devices, etc., can solve the problems of impossibility, difficulty, temperature reduction, etc., to ensure no deterioration and short reaction time , the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

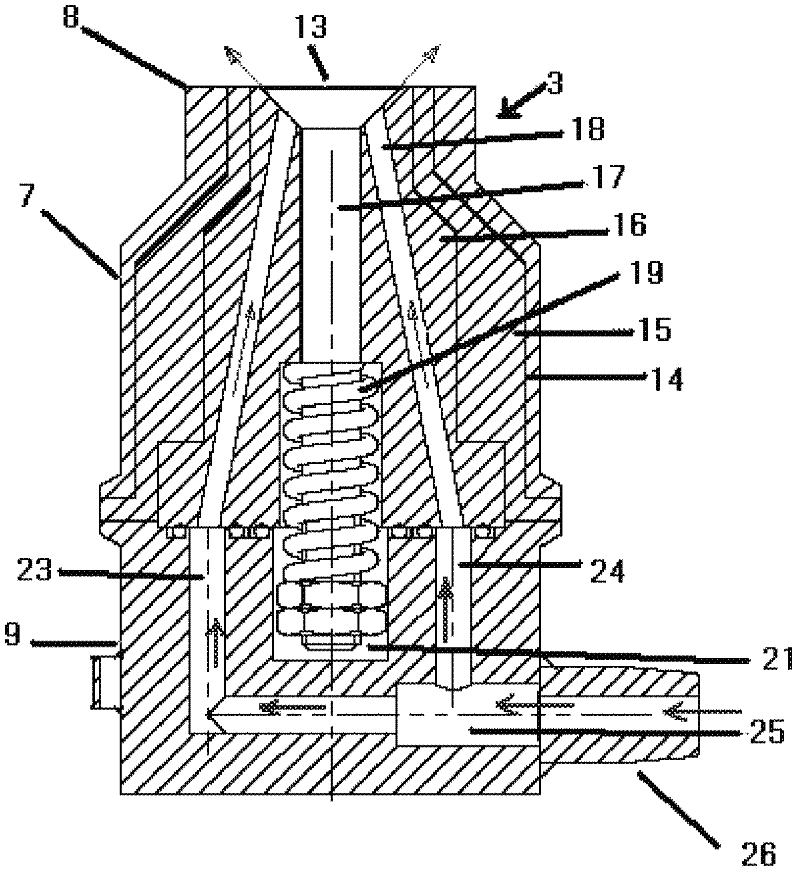

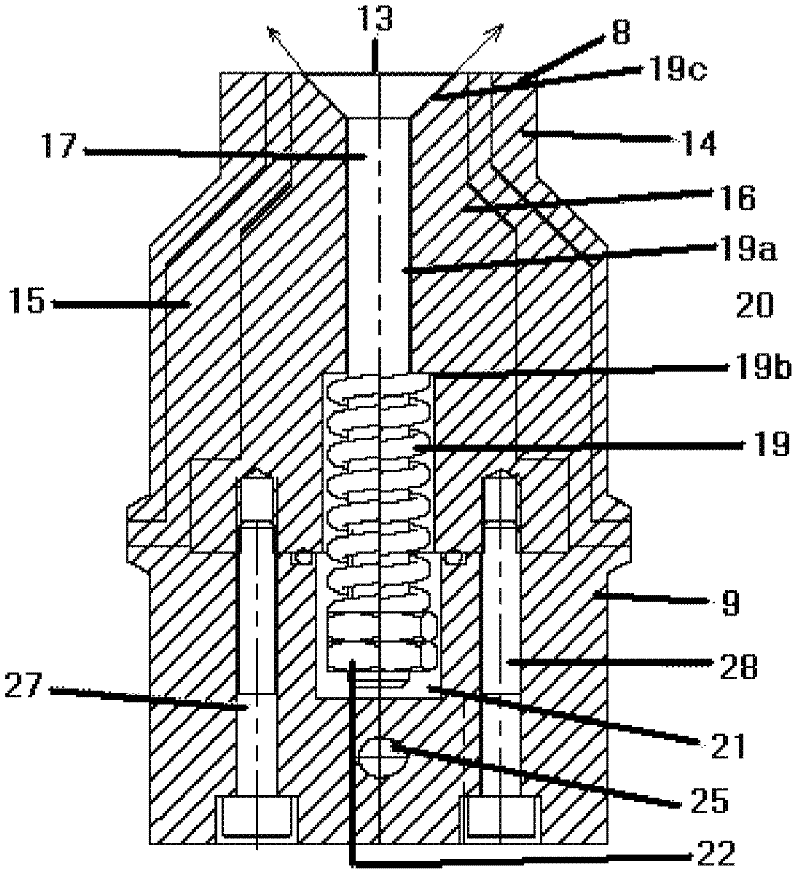

[0032] From figure 2 and 3 As can be seen more clearly in , the injection device 3 comprises a body consisting of two connected parts (lower part 9 and upper part 7 ). The upper part itself consists of three parts, (one of which is) a substantially cylindrical outer wall 14 made of stainless steel, which rests indirectly at one end on the lower part 9 and at the other end for fixing to the wall of the container.

[0033] Inside the outer wall 14 there are provided members of complementary shape, which are also hollow and insulating and which define thermal bridges. A third stainless steel part 16 is arranged inside said component and is penetrated in its center by a valve 17 and two through passages 18 in the beveled / conical shape of the component 16 for receiving the valve seat 13 of the valve 17 opening at the top.

[0034] The central through-opening of member 16 comprises three regions: a central region 19a, whose diameter is substantially equal to that of the valve, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com