Fusion bonded epoxy coating compositions that include magnesium oxide

A technology for epoxy coatings and compositions, applied in epoxy coatings, powder coatings, coatings, etc., can solve problems such as cracks and defects in pipeline coatings, achieve excellent resistance to cathodic disbondment, and improve adhesion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0080] All parts, percentages, ratios, etc. in the examples, as well as elsewhere herein, are by weight unless otherwise indicated.

[0081] materials used

[0082] Amicure CG-1400: Dicyanamide curing agent available from Air Products and Chemical, Inc., Allentown, PA.

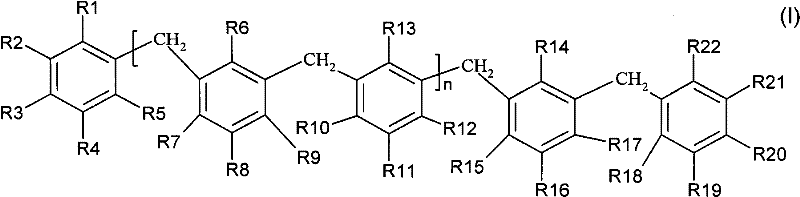

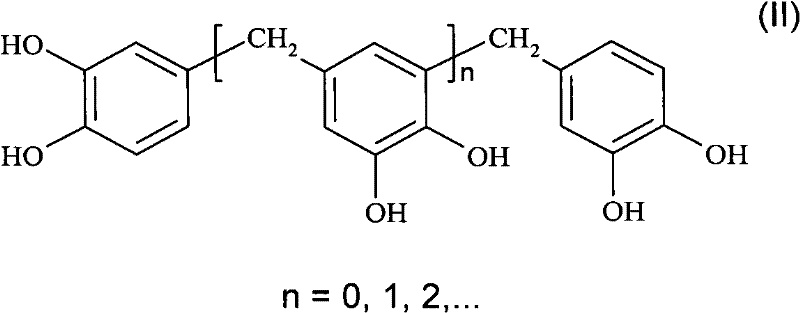

[0083] Catechol Novolak Blend - A 20:80 blend of catechol novolac resin and phenolic hardener resin, which is equivalent to the "ACN blend" described in US Patent No. 6,911,512.

[0084] Curezol C-17Z: Accelerator, available from Shikoku Chemicals Corp., Tokushima, Japan.

[0085] DER 6508: Isocyanate-modified epoxy resin available from Dow Chemical Corporation, Freeport, TX.

[0086] Dyhard 100M: Dicyanamide curing agent available from AlsChem LLC, Atlanta, GA.

[0087] EPI-CURE P100: Accelerator available from Hexion Specialty Chemicals, Columbus, OH.

[0088] EPON 2004 and EPON 1001F: epoxy resins available from Hexion Specialty Chemicals, Columbus, OH.

example 1 and 2 and comparative example A

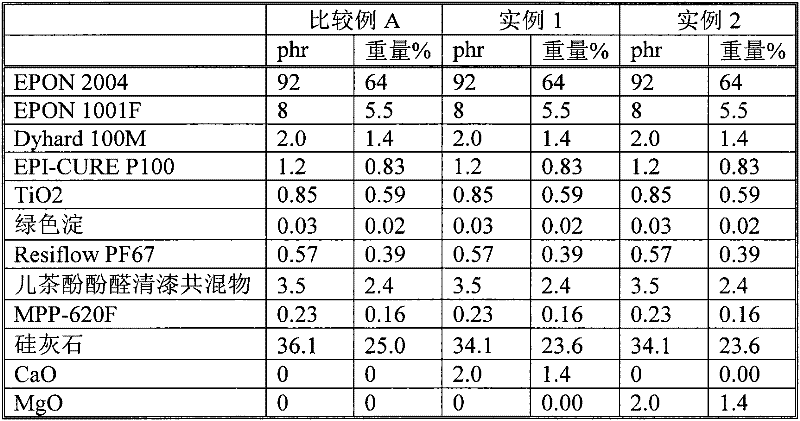

[0135] Examples 1 and 2 are powdery epoxy compositions prepared according to an exemplary embodiment of the present invention, which respectively have EPON 2004, EPON 1001F, Dyhard 100M, EPI-CURE P100, SMC 1108, phthalein as provided in Table 1 Component concentrations of Cyan Green Lake, Resiflow PF67, Catechol Novolak Blend, MPP 620F, Vansil W20, and Polycal OS 325 or Maglite A. Comparative example A is the composition of comparison, and it has EPON 2004, EPON 1004F, Dyhard 100M, EPI-CURE P100, SMC 1108, phthalocyanine green lake, Resiflow PF67, catechol novolac blending as provided in Table 1 products, MPP 620F and Vansil W20. The amounts shown in Table 1 are given in both relative parts by weight (parts per 100 parts by weight resin, phr) and percent by weight (wt%) of the coating composition.

[0136] Table 1

[0137]

[0138] Table 2 shows the results of the coated steel panel samples in the hot water adhesion test and cathodic disbondment test. Example 1 strongl...

Embodiment 3 and 4 and comparative example B

[0142] Examples 3 and 4 are powdery epoxy compositions prepared according to an exemplary embodiment of the present invention, which have DER 6508, EPON 2004, Amicure CG-1400, Curezol C-17Z, SMC 1108, Component concentrations of Phthalocyanine Green Lake, Resiflow PF67, Catechol Novolak Blend, ExBAR 400, Vansil W20 and Maglite A. Comparative Example B is a comparative composition, which has DER 6508, EPON 2004, CG-1400, Curezol C-17Z, SMC 1108, phthalocyanine green lake, Resiflow PF67, catechol novolac co- Blend, ExBAR 400 and Vansil W20. The amounts shown in Table 3 are given in both relative parts by weight (parts per 100 parts by weight resin, phr) and percent by weight (wt%) of the coating composition.

[0143] table 3

[0144]

[0145]

[0146] Table 4 shows the results of the coated steel panel samples in the hot water adhesion test and cathodic disbondment test. Note that for the hot water adhesion test, two separate scoring results are reported for each exam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap