Intermittent greenhouse light complementing system with automatic moving light source

An automatic moving and intermittent technology, which is applied in greenhouse cultivation, light source fixing, lighting device components, etc., can solve the problems of high energy consumption, failure to meet the control needs of plants for light interval and variability, and high cost investment. Problems, to achieve the effect of simple system structure, conducive to plant growth, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

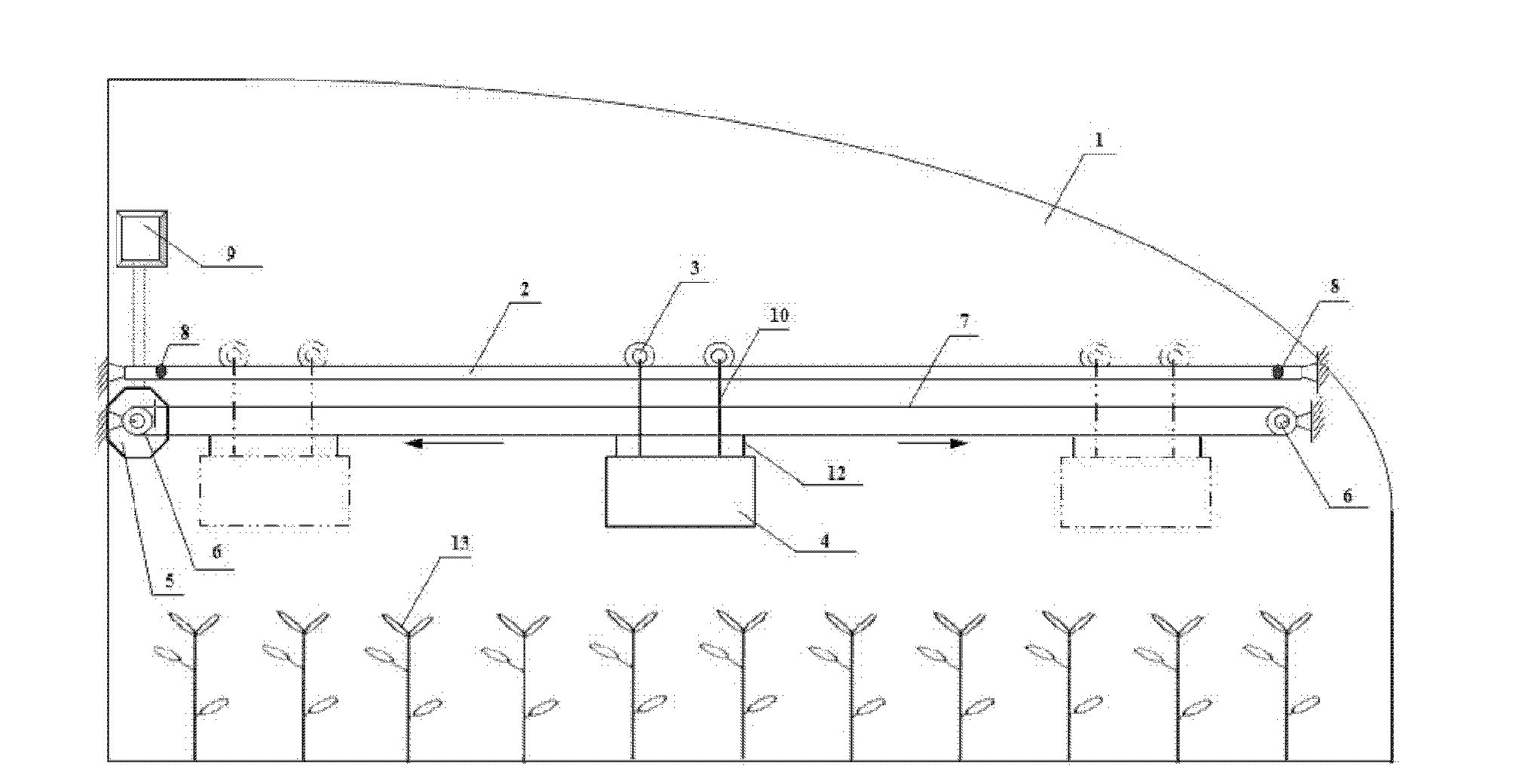

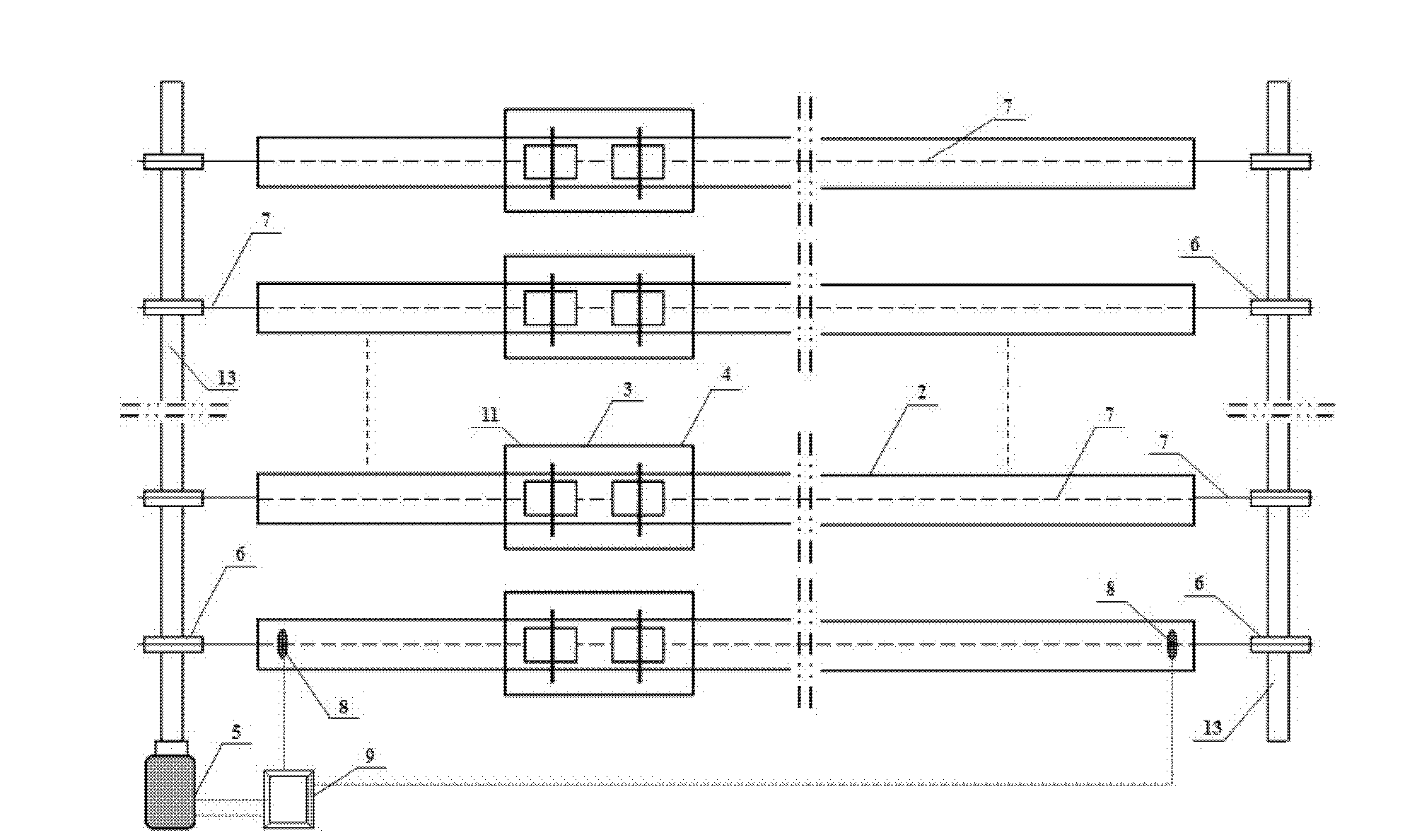

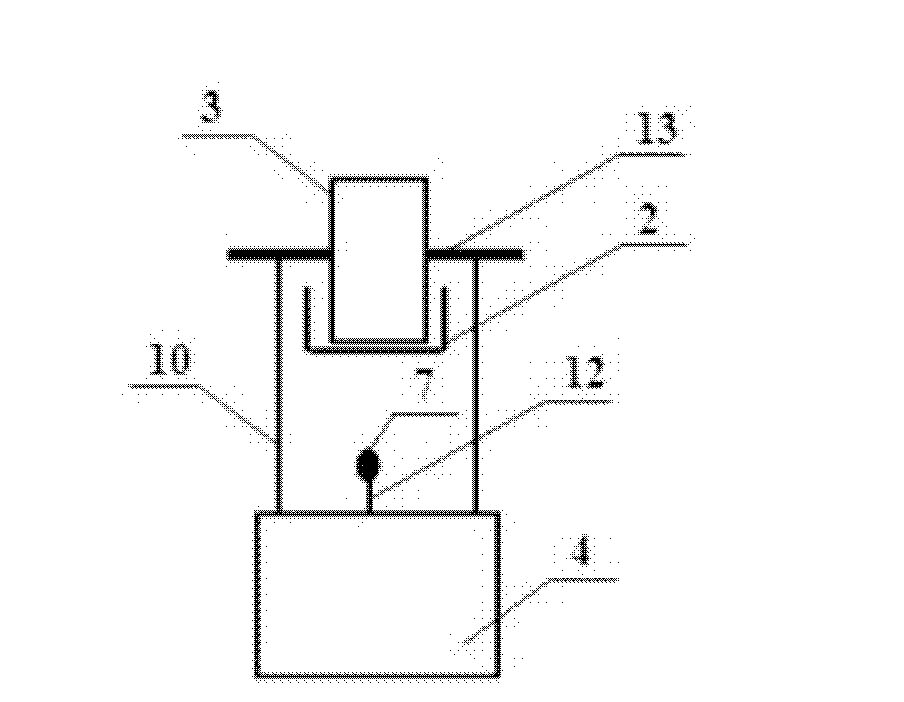

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] combine figure 1 , figure 2 , image 3 As shown, a guide beam 2 and a transmission device are installed at both ends of the greenhouse 1, and are fixed on the frame of the greenhouse 1. The transmission device is composed of a servo motor 5, two pulleys 6, and a transmission cable 7. The two pulleys 6 pass through the pulley shaft. 13 is installed on the two ends of the greenhouse 1, and the transmission cable 7 is arranged between the pulleys 6. The guide beam 2 is a track provided with a groove, and two road wheels 3 are arranged in the groove, and the roller shafts 11 of the two road wheels 3 hang the electric light source device 4 below through the telescopic suspension rod 10, and the electric light source device 4. The front and back are also connected with the transmission cable 7 by two connecting rods 12. The electric light source device 4 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com