Abrasion test device for tibiofemoral joint of bi-dimensional rotating and bi-dimensional movement synthesized knee replacement prosthesis

A wear test and motion synthesis technology, applied in the direction of prosthesis, medical science, etc., can solve the problems of immaturity and perfection of joint prosthesis, and achieve the effect of strong adjustability, accurate wear characteristics and wear prediction, and many degrees of freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

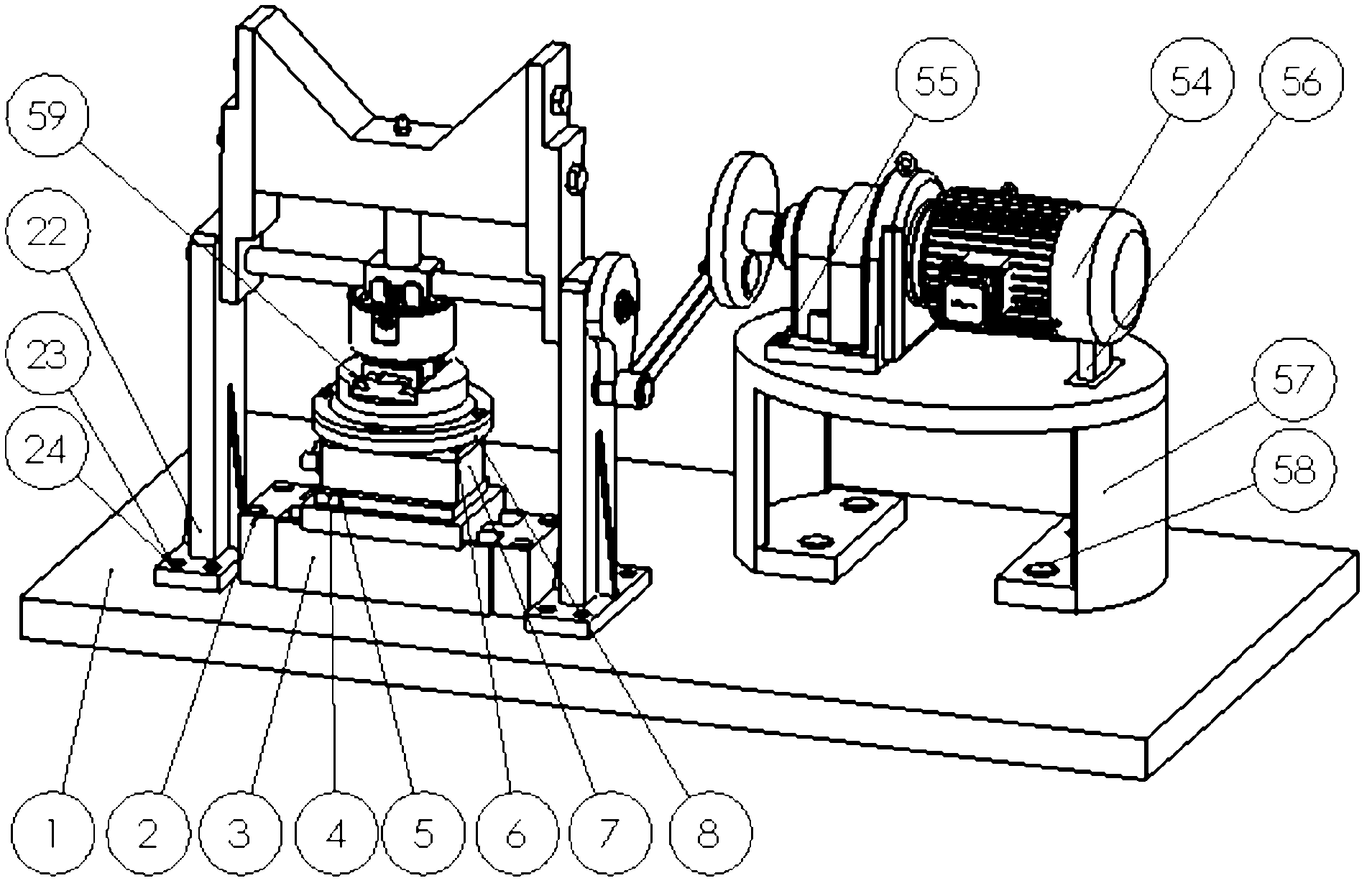

[0022] Further elaborate the technical scheme of the present invention in conjunction with accompanying drawing:

[0023] See figure 1 , the present invention is a synthetic knee replacement prosthesis tibiofemoral joint wear test machine with two rotations and two shifts, which is composed of two parts, the right part and the left part, and the position connection relationship between them is: the left part is on the left side of the testing machine. The right part is on the right side of the testing machine, and the rocker in the crank-rocker mechanism in the right part is connected with the main shaft in the femoral system in the left part.

[0024] The left part produces the flexion and extension wear motion between the joint surfaces of the prosthesis, and the right part is the driving structure in the flexion and extension motion of the prosthesis joint.

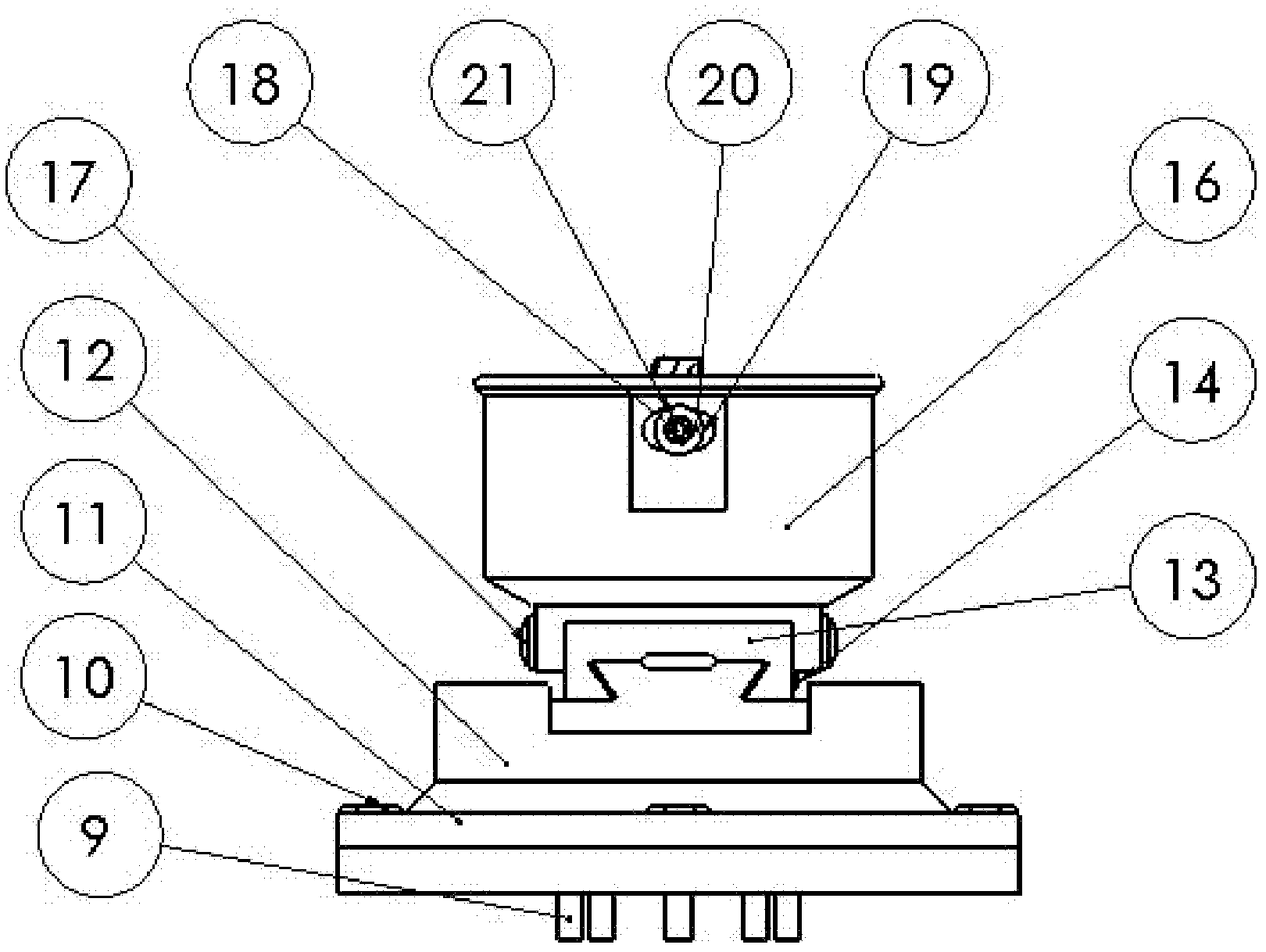

[0025] The technical scheme and principle of the left part:

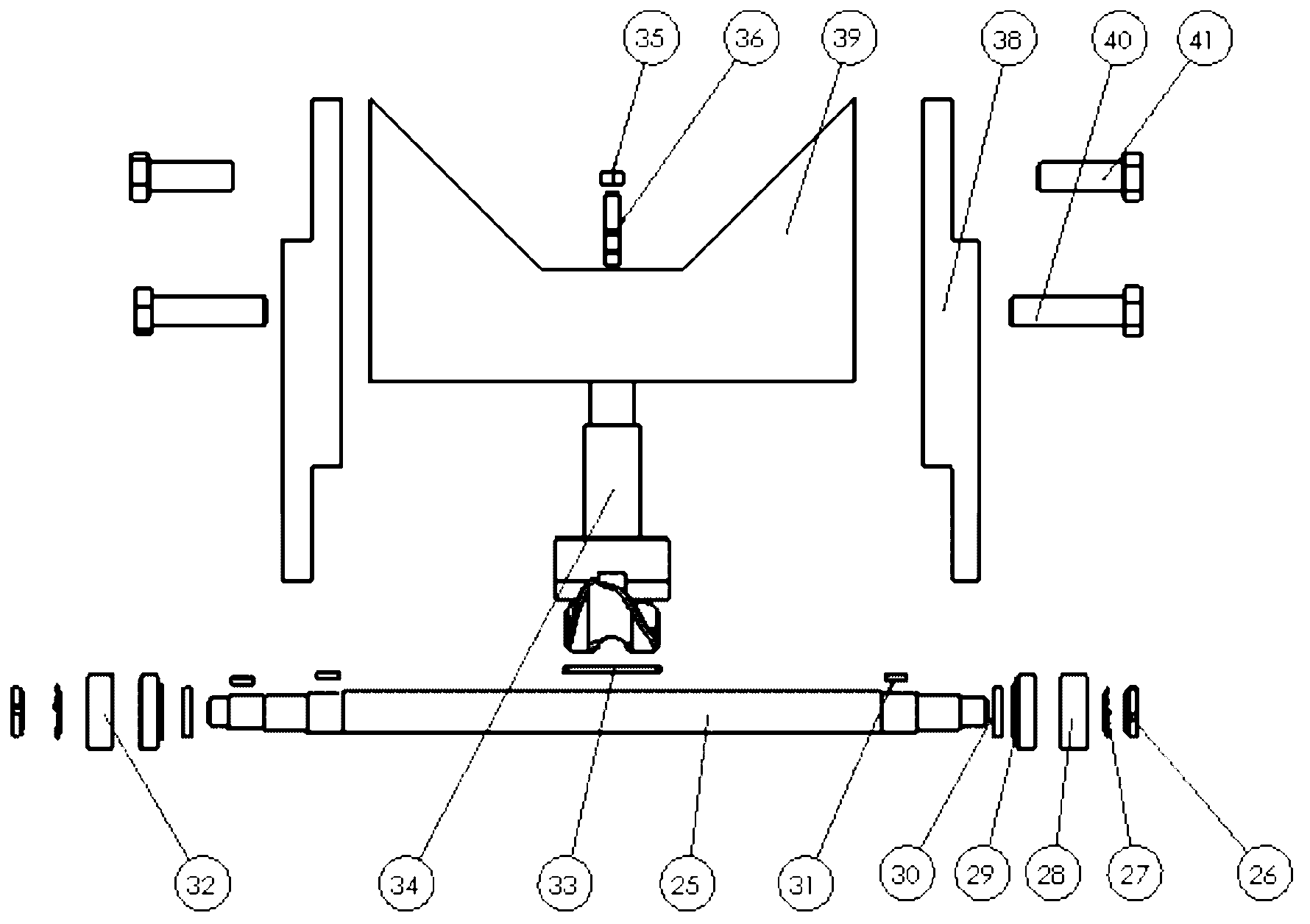

[0026] The left part mainly includes a main shaft 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com