Self-locking lining board device of horizontal roller mill

A technology of horizontal roller mill and lining plate, applied in the field of horizontal roller mill, can solve the problems of increasing the difficulty of replacing the lining plate and bolts, damaging the overall structural performance of the cylinder, plastic deformation of the lining plate and bolts, etc., so as to eliminate the risk of falling off and eliminate the Wear phenomenon, effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

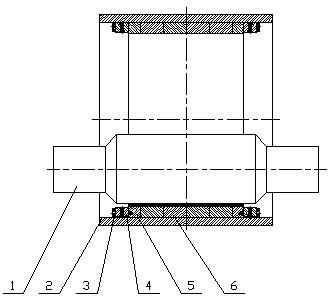

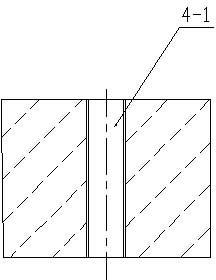

[0023] The technical solution of this specific embodiment includes: a fixed retaining ring 3, a wedge-shaped block 4, a self-locking liner (1) 5, and a self-locking liner (2) 6.

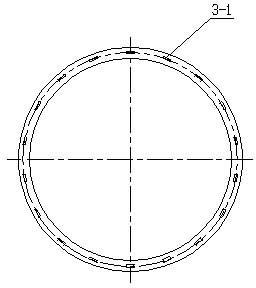

[0024] The fixed retaining ring 3 has an inner and outer arc surface structure, and its outer arc surface is rigidly connected with the inner wall of the horizontal roller mill cylinder 2 . A plurality of waist-shaped through-holes 3-1 are uniformly opened on the fixed retaining ring 3, and the number of waist-shaped through-holes 3-1 is the same as that of the circumferential self-locking liner (1) 5 and self-locking liner (2) 6 Quantity is equal, and waist-shaped through hole 3-1 diameter is identical with self-locking liner (one) 5, self-locking liner (two) 6 side threaded holes 5-1 diameters, and its center is on the same line.

[0025] The wedge-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com